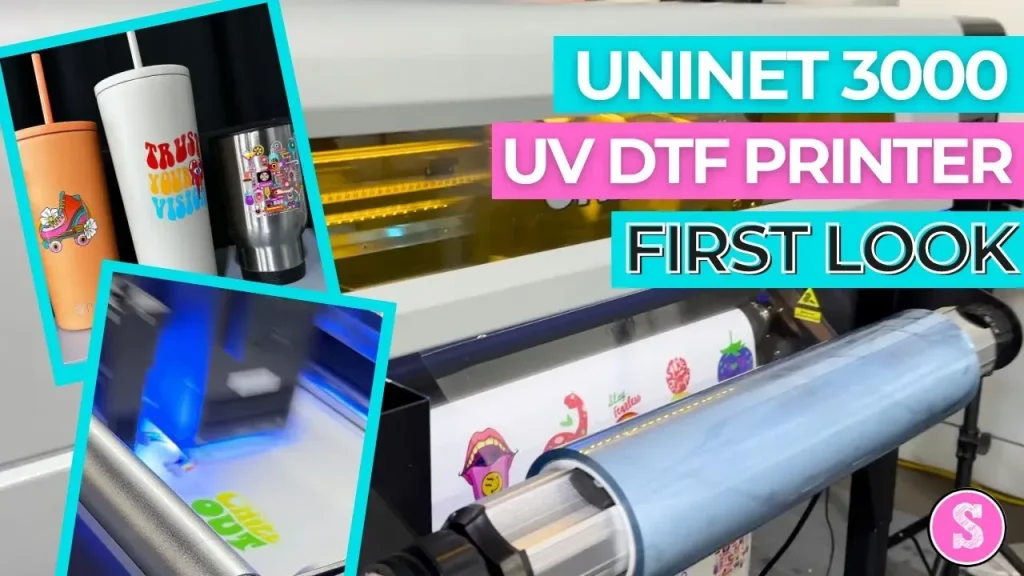

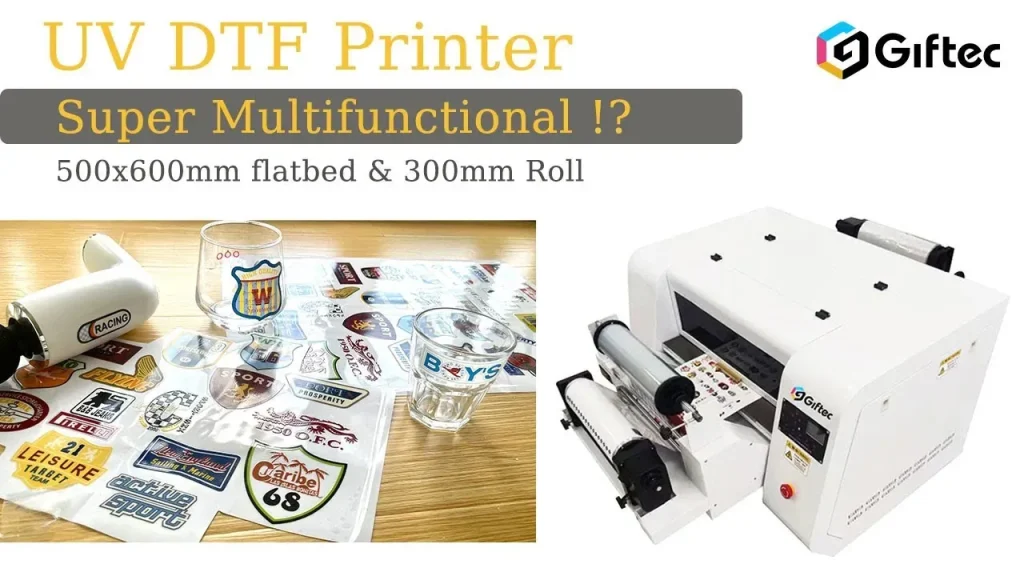

UV DTF Printing: Why It’s Gaining Momentum in 2025

UV DTF is redefining the printing landscape by marrying the flexibility of direct-to-film with the speed of UV-curable inks, empowering designers to explore complex graphics with production efficiency.UV DTF printing delivers vibrant, durable results that align with evolving needs in the apparel space and offer sharp color and reliable wash performance for a range of fabrics.

UV DTF Printing: Why It’s Gaining Momentum in 2025 Read More »