In the ever-evolving arena of printing technology, UV Direct-to-Film (DTF) is carving out a prominent place as a modern marvel that industry professionals cannot afford to overlook. This inventive process synthesizes traditional printing methods with cutting-edge technology, enabling businesses to achieve exceptional results with incredible speed and efficiency. With its extensive range of UV DTF applications and superior output quality, this printing technique is rapidly gaining traction among those seeking sustainable printing solutions. The benefits of UV DTF printing extend far beyond appearance; they bring durability, color vibrancy, and reduced environmental impact to the forefront of the industry. As an essential component of future printing endeavors, understanding UV DTF technology will empower print companies to adapt and thrive in a competitive marketplace.

When discussing advanced printing techniques, terms such as UV Direct-to-Film (DTF) often emerge at the forefront, highlighting the significant transformations in contemporary printing workflows. This innovative approach harnesses the strengths of ultraviolet curing technology, reflecting a shift towards more efficient and sustainable methods in the printing sector. The versatility of UV DTF applications allows for a broad spectrum of creative expressions, making it an attractive choice for various industries. As businesses increasingly prioritize eco-friendly printing practices, the remarkable benefits associated with UV DTF printing are proving to be crucial for meeting modern consumer demands. Ultimately, embracing this state-of-the-art printing technology represents a pivotal step for manufacturers aiming to enhance their production capabilities and market competitiveness.

Understanding UV Direct-to-Film Printing

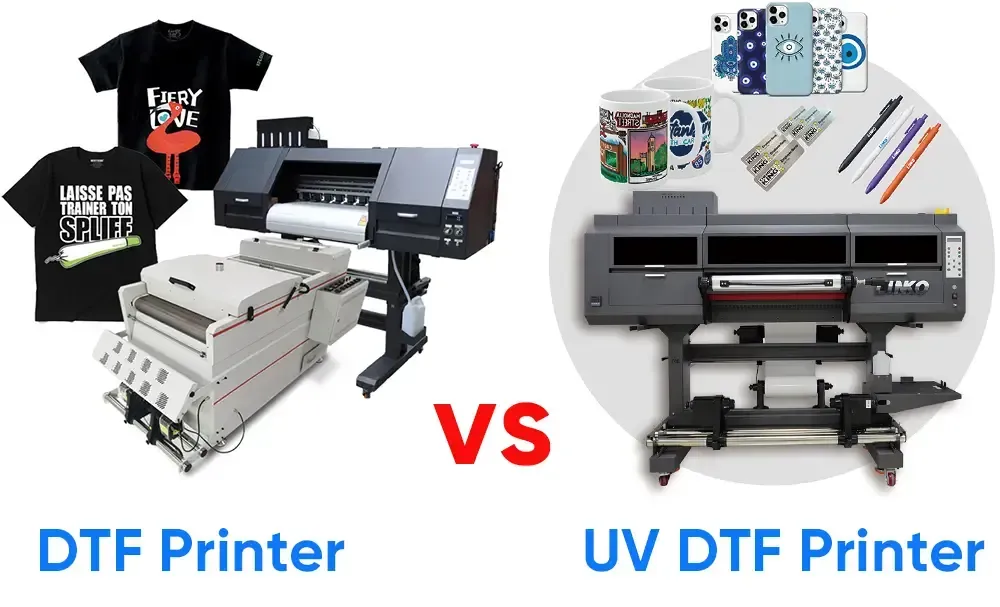

UV Direct-to-Film (DTF) printing represents a significant breakthrough in printing technology, combining the advantages of traditional methods with the innovative features of UV curing. This technique allows for the direct transfer of high-resolution images onto various substrates using UV-curable inks – a fact that drastically enhances color vibrancy and detail. Unlike conventional DTF printing, which may have limitations regarding material compatibility, UV DTF printing excels in its versatility, accommodating materials like textiles, metals, glass, and plastics, thereby appealing to a broader range of industries.

The process involves printing an image onto a special film that is then transferred to the desired surface using a heat press. This unique method not only modernizes printing techniques but significantly enhances efficiency and scalability for production runs. As businesses strive to meet the demands of a fast-paced market, understanding the intricacies of UV DTF printing becomes crucial, enabling them to harness its capabilities for customized applications in apparel, signage, and promotional items.

The Advantages of UV DTF Printing

One of the standout advantages of UV DTF printing is its exceptional quality and durability. The UV curing process ensures that prints dry instantly, offering immediate usability without compromising on visual appeal. This technology produces prints that are resistant to fading, scratching, and environmental factors, thereby increasing the longevity of the finished products. As a result, businesses can assure their customers of high-quality products that maintain their integrity over time, especially in outdoor applications where exposure to harsh conditions is expected.

Furthermore, the efficiency that UV DTF printing brings to production cannot be overstated. With the ability to execute faster turnaround times without sacrificing quality, companies can respond more quickly to customers’ needs and stay competitive in a crowded market. This ability to quickly produce high-quality prints positions UV DTF as a top choice for small to medium-sized businesses looking to elevate their service offerings.

Emerging Trends in UV DTF Applications

As UV DTF printing gains traction, its applications are rapidly expanding across various sectors, making it an increasingly important consideration for businesses. From custom apparel to intricate signage and promotional materials, the versatility of UV DTF technology provides endless possibilities for creative expression. The ability to print on diverse substrates allows companies to cater to a wide range of customer preferences, hence driving market growth and adoption.

The demand for personalized products is on the rise, and UV DTF printing enables businesses to easily cater to this trend with high-quality customization options. Whether for event branding, bespoke merchandise, or unique gifts, the ability to produce short runs of customized items efficiently showcases the capacity of UV DTF technology to meet modern consumer demands.

User-Friendly Innovations in UV DTF Printing

Major equipment manufacturers have been diligent in creating user-friendly UV DTF printing solutions, effectively democratizing access to advanced printing technology. The introduction of intuitive machines designed for smaller businesses and entry-level users means that high-quality printing is no longer exclusive to large print houses. By lowering the barriers to entry, more organizations can leverage UV DTF printing to enhance their product offerings without a steep learning curve.

This user-centric approach helps to foster innovation and creativity within the industry, as more users experiment with the technology. As a result, we see a diverse range of applications emerge, from artisanal crafts to commercial projects, that showcase the potential of UV DTF printing. Collectively, these advancements suggest a promising future for the printing industry, driven by accessibility and creativity.

Sustainability in UV DTF Printing

Sustainability is a significant trend influencing modern manufacturing processes, and UV DTF printing is at the forefront of this movement. The energy-efficient UV curing process curtails energy consumption compared to traditional printing methods, while the precision of ink application reduces waste. Companies that adopt UV DTF technology not only improve their operational efficiency but also align their production practices with growing consumer demand for environmentally responsible products.

In addition to lowering energy usage and waste, UV DTF printing facilitates the use of eco-friendly inks, which further enhances its appeal to businesses aiming for sustainability. As more enterprises prioritize green practices, UV DTF is positioned as a leading technology that supports the transition towards environmentally-conscious printing solutions.

Future Innovations in UV DTF Technology

The landscape of UV DTF printing continues to evolve, promising exciting advancements in the years to come. Trade shows like the ISA Sign Expo showcase innovative machines and technologies that enhance printing efficiency and capabilities, reflecting the industry’s commitment to continuous improvement. As technology becomes more sophisticated, it is expected that UV DTF printing will see enhancements in speed, quality, and the range of materials that can be utilized.

Investing in the latest UV DTF technology could provide print businesses with a significant competitive edge, allowing them to stay ahead of market trends and customer expectations. The ongoing evolution of this printing method assures that companies can not only maintain high standards but also push the creative boundaries of print production to drive future success.

Frequently Asked Questions

What is UV Direct-to-Film (DTF) printing and how does it work?

UV Direct-to-Film (DTF) printing is a modern printing technology that utilizes UV-curable inks to transfer vibrant designs directly from a film onto various substrates using a heat press. This process ensures high-resolution prints and allows for immediate curing, resulting in quicker production times.

What are the key benefits of UV DTF printing for businesses?

UV DTF printing offers several advantages, including superior quality with vibrant colors, exceptional durability against fading and scratching, and fast production times due to instant ink curing. Additionally, it aligns with sustainable printing practices by reducing ink waste and energy consumption.

What kind of applications can benefit from UV DTF technology?

UV DTF technology is versatile, suitable for a wide range of applications including custom apparel, signage, promotional materials, and decorative items. Its durability and high-quality output make it ideal for both indoor and outdoor uses.

How does UV DTF printing compare to traditional printing methods?

Compared to traditional printing methods, UV DTF printing provides enhanced color vibrancy, quicker processing times, and greater durability. Moreover, it minimizes the risk of ink smudging or running, making it a more reliable choice for high-quality prints.

Is UV DTF printing a sustainable option for companies focused on eco-friendly practices?

Yes, UV DTF printing is considered a sustainable option as it utilizes UV curing technology that requires less energy compared to conventional methods and significantly reduces ink waste. This makes it a favorable choice for environmentally conscious businesses.

What recent innovations are influencing the future of UV DTF printing?

Recent innovations in UV DTF printing include the development of user-friendly printing machines aimed at small businesses and entry-level users. Industry trade shows are showcasing advancements that enhance printing capabilities and efficiency, highlighting the continual evolution of this technology.

| Key Points | Details |

|---|---|

| What is UV DTF Printing? | A method that uses UV-curable inks for high-quality prints on various substrates, enhancing traditional printing techniques. |

| Superior Technology Integration | Instant drying of inks allows faster production, improved color quality, and reduced costs compared to conventional methods. |

| Exceptional Quality and Durability | UV DTF prints resist fading and scratching, maintaining quality for both indoor and outdoor usage. |

| Growing Market Adoption | Increasing recognition among businesses with a projected rise in the global UV printing market due to its efficiency and cost-effectiveness. |

| User-Friendly Solutions | Development of accessible UV DTF printing machines for small businesses, broadening the technology’s reach. |

| Commitment to Sustainability | Lower energy use and reduced ink waste position UV DTF as an eco-friendly option in modern manufacturing. |

| Recent Innovation Trends | Ongoing advancements and new machines showcased at industry trade shows demonstrate the evolving capabilities of UV DTF technology. |

Summary

UV DTF printing represents a remarkable advancement in the printing sector, boasting numerous benefits that make it an essential consideration for any printing professional. This innovative technology combines traditional printing methods with modern capabilities, resulting in stunning, durable prints suitable for a variety of applications. With rapid market adoption, businesses are increasingly drawn to UV DTF for its efficiency, cost-effectiveness, and environmental advantages. As the industry continues to innovate, understanding UV DTF will not only enhance printing services but also pave the way for new creative possibilities in the realm of print production.