DTF transfers, a game-changer in the printing industry, utilize Direct-to-Film technology to deliver stunning designs directly onto garments. This innovative process allows for heat transfer of high-quality prints from film, making it a preferred choice among businesses seeking to create vibrant, durable apparel. As we delve deeper into the advantages of DTF printing, we’ll uncover how it promotes creativity through customization in printing while reaching eco-conscious consumers with its sustainable practices. Not only do DTF transfers provide versatility across various fabric types, but they also adapt to current DTF market trends like personalization and rapid production capabilities. Join us as we explore this fascinating evolution and see why DTF transfers are emerging as the leading printing solution for 2024.

As we explore the world of Direct-to-Film (DTF) technology, it’s worth noting that this approach to textile printing represents a significant advancement in the customization and personalization of apparel. With its ability to create stunning, detailed designs on various fabric types, this method stands out among traditional printing techniques. In light of growing interest in sustainable practices, DTF solutions also contribute to eco-friendly printing solutions by minimizing resource use and incorporating safer inks. Additionally, the DTF methodology taps into current trends by allowing for quick turnaround times, appealing to the fast-paced demands of modern consumers. By embracing these innovative printing solutions, businesses can meet consumer needs for both quality and sustainability in the ever-evolving market.

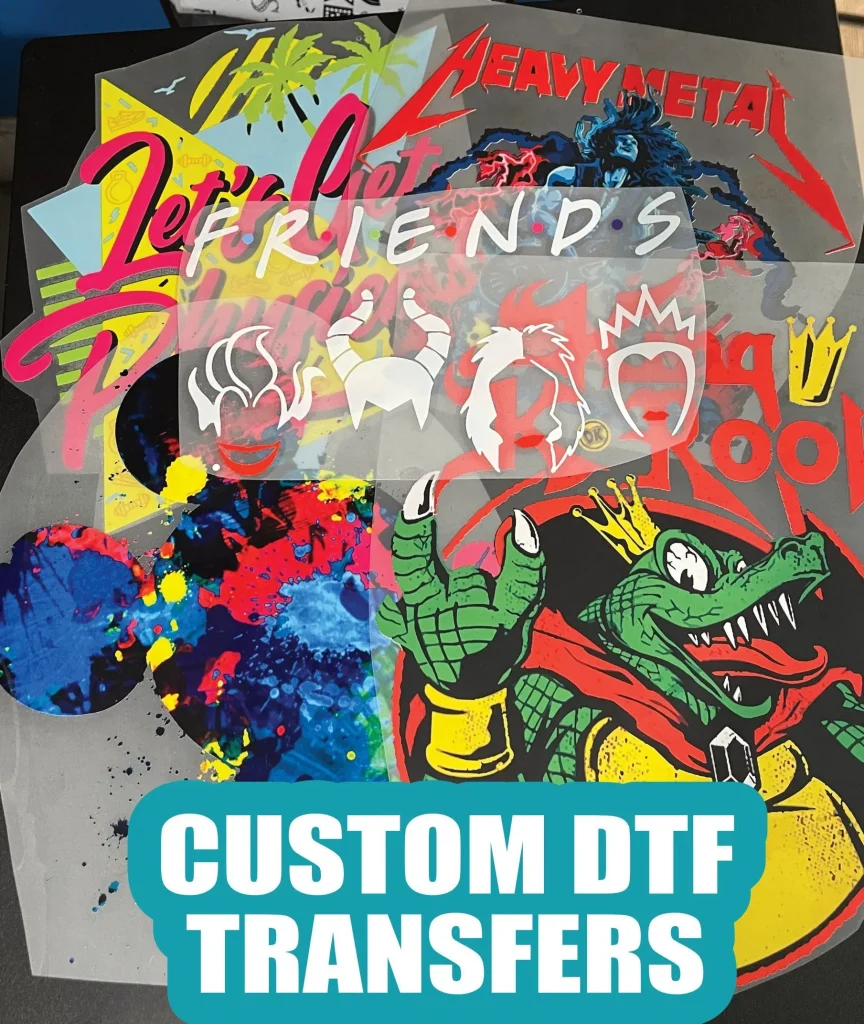

Understanding DTF Transfers: A Game Changer in Textile Printing

Direct-to-Film (DTF) transfers represent a significant shift in the methods used to print designs onto apparel. This technique is fundamentally different from traditional textile printing methods like screen printing or direct-to-garment (DTG) printing. With DTF transfers, inks are printed on a special film that captures vibrant colors and intricate details, which can then be transferred onto various fabric types using heat. This unique approach ensures that the quality of the print remains high, making DTF a preferred choice among fashion brands looking to maintain a competitive edge.

The rise of DTF technology is largely due to its versatility and superior output quality. Unlike other methods, DTF can be employed on various fabrics, including cotton, polyester, and blends. The ability to produce sharp images with a broad color spectrum is pivotal for designers and brands looking to stand out in a crowded marketplace. As consumers increasingly demand unique and personalized items, DTF transfers allow businesses to cater to these preferences without compromising on quality.

The Advantages of DTF Printing

DTF printing has numerous benefits that make it an appealing choice for many businesses in the textile industry. One of the foremost advantages is the impressive quality of the prints. DTF transfers produce sharp details and a wide color range that rivals that of any other printing method. This level of detail is particularly essential for brands that rely on intricate designs and want to attract customers through visually appealing products.

Another significant advantage of DTF printing is its ease of use and speed of production. For businesses facing tight deadlines, DTF transfers enable quicker turnaround times compared to traditional printing methods. As the demand for fast fashion continues to grow, the efficiency of DTF printing can offer manufacturers a substantial boost in productivity, allowing them to meet customer expectations with timely deliveries.

Technological Innovations in DTF Transfers

The landscape of DTF transfers is profoundly influenced by technological advancements, particularly in the printing equipment used. Newer DTF printers are equipped with faster printing capabilities and enhanced ink systems that mitigate common issues like ink bleeding. This evolution not only enhances the overall quality of the prints but also improves the workflow, making it easier for businesses to scale production.

Furthermore, ongoing innovations in ink formulations are propelling DTF technology into an era of superiority. Manufacturers are developing vibrant inks that prioritize durability while being less harmful to the environment. This focus on optimizing quality and sustainability aligns with the contemporary consumer’s preference for eco-friendly products, making DTF a relevant choice in today’s responsibly-conscious market.

The Market Trends Impacting DTF Printing

As we approach 2024, the DTF printing market continues to expand at a remarkable pace. More companies, particularly small and medium-sized enterprises, are embracing this cost-effective solution due to its lower entry requirements. The decreasing costs of DTF printers and printing materials open doors for start-ups to enter the customization market, capitalizing on the growing demand for personalized products.

The convenience and flexibility offered by DTF printing positions it as a key player in meeting the shifting consumer trends toward individuality. As customers increasingly seek distinct and customized apparel, DTF technology provides businesses with the tools to deliver personalized designs efficiently, thus enhancing customer satisfaction and loyalty.

The Role of Eco-Friendly Practices in DTF Printing

In an age where sustainability influences consumer preferences, DTF printing emerges as a viable eco-friendly alternative to traditional methods like screen printing. The DTF process significantly reduces water usage, making it an attractive option for environmentally-conscious businesses looking to minimize their ecological footprint. This aspect of DTF transfers aligns with the global trend towards adopting greener manufacturing practices.

Additionally, advancements in DTF inks are leading manufacturers to produce products that are free of harmful chemicals. This focus on safe inks not only resonates with consumers but also contributes positively to workplace safety. As the demand for sustainable solutions grows, adopting DTF technology places businesses at the forefront of this vital movement within the printing industry.

Customization and Personalization: The Future of DTF Printing

Customization has become a defining feature in contemporary consumer culture, and DTF transfers are positioned to lead this charge in the textile industry. The technology enables brands to create high-quality personalized products that cater to the unique preferences of individual customers. With DTF, businesses can produce an array of customized designs effortlessly, thus enhancing their market appeal.

As competition heightens in the textile market, offering personalized options can significantly boost customer loyalty and retention. By tapping into this customization trend, businesses are not just meeting current consumer demands; they are also potentially unlocking new revenue streams by catering to niche markets. Embracing DTF printing provides an excellent avenue for brands to differentiate themselves and capitalize on the growing desire for individual expression through apparel.

Frequently Asked Questions

What are the main advantages of DTF transfers in textile printing?

DTF transfers offer numerous advantages in textile printing, including high-quality results with sharper details and vibrant colors, versatility for use on different fabric types, and ease of use that allows for faster production times. This makes DTF printing an excellent choice for businesses looking to produce high-quality customized products efficiently.

How does Direct-to-Film technology differ from traditional printing methods?

Direct-to-Film (DTF) technology differs from traditional methods like screen printing by utilizing a specialized film that receives the print before being transferred onto fabrics. This process enhances durability, color vibrancy, and compatibility with various fabric types, significantly improving the quality of printed designs compared to traditional techniques.

What recent market trends are influencing the adoption of DTF printing?

Recent market trends driving the adoption of DTF printing include growing consumer demand for customization and personalization, lower entry costs for DTF technology, and an increased focus on eco-friendly printing solutions. These trends position DTF transfers as a preferred choice for businesses aiming to meet modern consumer preferences.

Are there eco-friendly benefits associated with DTF transfers?

Yes, DTF transfers are considered an eco-friendly printing solution due to reduced water usage and the availability of safe ink options that are free from harmful chemicals. This aligns with the industry’s broader initiative to adopt greener practices, making DTF an appealing choice for environmentally conscious businesses.

How can businesses leverage DTF printing for customization in apparel?

Businesses can leverage DTF printing for customization by utilizing its ability to produce high-quality images and designs. This technology allows for tailored solutions that resonate with individual customers, enabling businesses to capitalize on niche markets and enhance customer loyalty through personalized apparel offerings.

What should companies consider before investing in DTF transfer technology?

Before investing in DTF transfer technology, companies should consider the cost of equipment and materials, the expected return on investment from increased production efficiency, the demand for customized products in their target market, and their commitment to implementing eco-friendly practices as consumer preferences shift towards sustainability.

| Key Features of DTF Transfers | Overview | Advantages | Trends and Innovations | Market Impact | Sustainability | Customization |

|---|---|---|---|---|---|---|

| Definition of DTF Transfers | Revolutionary printing method that applies designs using a film. | High-quality print with vibrant colors and excellent durability. | Emerging printer technologies and improved ink formulations. | Robust market growth with increased accessibility for businesses. | Less water usage and safer ink options contribute to eco-friendliness. | High-quality personalization fosters individuality among consumers. |

| Technological Advancements | New printers with fast speeds and better ink systems. | Versatile for various fabric types, including cotton and blends. | Automation and efficient workflows enhance productivity. | Lower entry costs making it feasible even for small businesses. | Manufacturers produce eco-friendly inks for sustainability. | Opportunity for niche markets through tailored offerings. |

Summary

DTF transfers are becoming a pivotal printing solution in the textile industry as we head into 2024. This innovative method not only enables high-quality and vibrant designs but also addresses market demands for eco-friendly practices and customization. The continual advancements in technology, alongside a focus on sustainability, suggest that DTF transfers will redefine how businesses approach garment printing. Companies that embrace these changes can expect to thrive in an evolving landscape that values individuality and environmental responsibility.