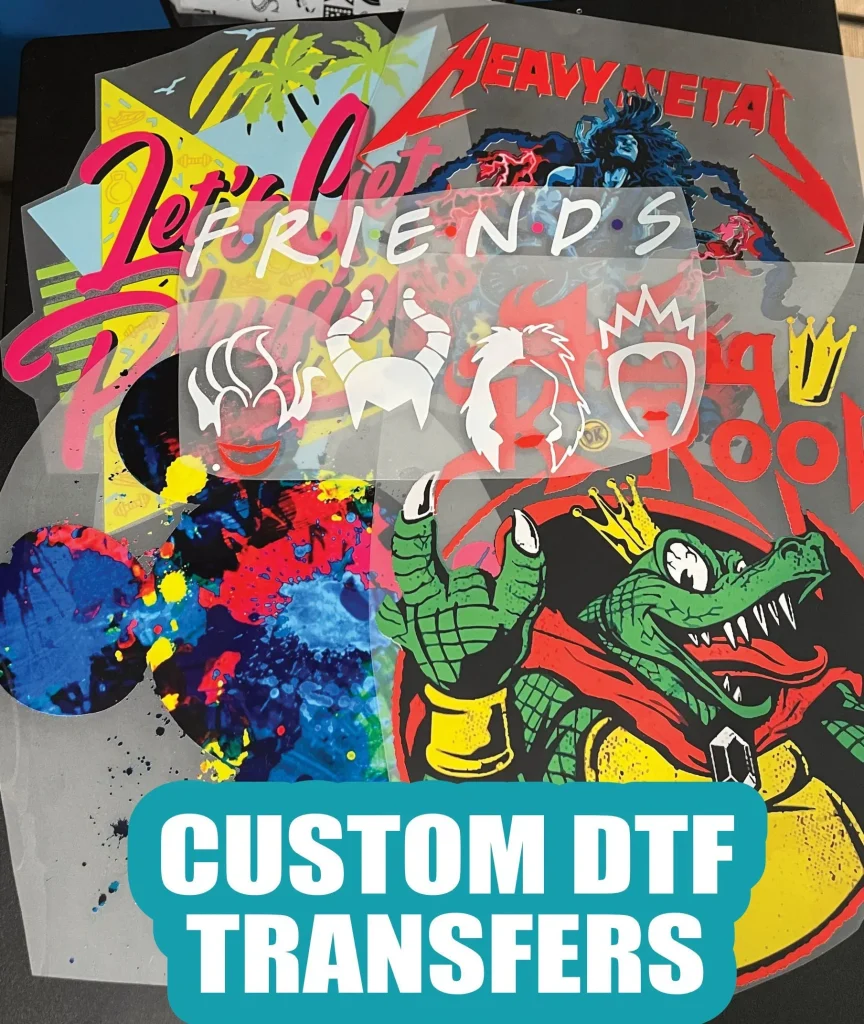

DTF transfers, or Direct-to-Film transfers, are revolutionizing the way we approach fabric printing, offering a dynamic solution for creating custom designs with unmatched vibrancy and durability. This innovative method allows you to print intricate graphics directly onto a special film before transferring them onto fabric, ensuring that colorful images maintain their clarity and wash resistance. As the market for DTF printing expands, both beginners and seasoned print makers are eager to master the essential DTF transfer techniques that can elevate their creative output. By utilizing high-quality materials and adhering to best practices in artwork preparation and heat pressing, you can produce stunning results that meet the demands of today’s consumers. Dive into the world of DTF transfers and unlock new possibilities for your custom fabric printing projects now!

Explore the fascinating landscape of Direct-to-Film printing, a method that transforms the way you apply designs to textiles. Often referred to as DTF printing, this approach utilizes a specialized film that effectively transfers colorful, high-definition images onto various fabric surfaces. The excellent performance of DTF transfer applications makes it a favored choice among creators seeking to produce unique, custom pieces. With its ability to yield stunningly vibrant fabric printing results, mastering the intricacies of this technique will empower you to stand out in the competitive print market. Discover the essential strategies and tools necessary for honing your skills in this innovative area of design!

Introduction to DTF Printing

Direct-to-Film (DTF) printing is revolutionizing the custom printing landscape by enabling creators to effortlessly produce stunning, high-resolution designs on a wide array of fabrics. Unlike traditional methods, DTF transfers utilize a unique printing process that allows for intricate designs and vibrant colors to be transferred directly onto the fabric. This technique not only ensures the longevity of the designs but also maintains their vividness even after multiple washes. For anyone involved in fabric printing, understanding DTF printing is essential for maximizing creativity and efficiency.

One of the key features of DTF printing is its adaptability to different materials, making it ideal for everything from cotton to polyester blends. This versatility means that fashion designers, promotional product creators, and hobbyists can utilize DTF transfers to bring their artistic visions to life. The ability to print detailed artwork without limitations on color or complexity is a game-changer, opening new avenues for customization and personal expression in fashion and merchandise.

Essential Supplies for DTF Transfers

When it comes to achieving professional-grade DTF transfers, selecting top-quality materials is paramount. Users should start with high-quality DTF films and inks, which are crucial for ensuring bright colors and strong adherence to various fabrics. Trusted brands such as Avery Dennison and Stahls’ have developed materials specifically engineered for DTF printing, enhancing the overall outcome of each design. Investing in superior supplies not only guarantees stunning results but also minimizes the chances of issues such as ink bleeding or poor transfer durability.

In addition to quality films and inks, it is also important to have the right equipment on hand, such as a reliable heat press. Heat presses designed for DTF transfers can provide the precise temperature and pressure necessary to ensure an effective transfer. Having the correct tools and supplies simplifies the printing process, leading to faster production times and higher customer satisfaction due to the exceptional finish of the final product.

Artwork Preparation for DTF Transfers

Meticulous artwork preparation is critical for the success of DTF transfers. Utilizing graphic design software such as Adobe Illustrator or Photoshop is recommended to create custom DTF designs that are sharp and vibrant. Designers should focus on creating vector files, which allow for resizing without loss of detail, making them perfect for any garment size or format. Additionally, ensuring that artwork is set at 300 DPI is essential for achieving high-resolution prints that capture the intricacies of the design.

Another key aspect of artwork preparation is color management. Using the right color profiles can significantly affect the outcome of the printed designs, leading to more accurate color reproduction. It is advisable to run test prints to evaluate how colors appear on different fabrics. Properly preparing and managing your artwork not only ensures a stunning final product but also helps streamline the printing process.

Understanding DTF Transfer Techniques

Mastering DTF transfer techniques encompasses a wide range of best practices that can enhance the quality and durability of prints. It’s important to adhere to recommended heat settings; generally, DTF transfers require a heat press temperature between 320°F and 330°F along with consistent pressure for around 15-20 seconds. Adjustments in time and temperature can depend on fabric types, and experimentation may be necessary to determine the optimal settings for each unique combination.

Furthermore, layering techniques in DTF printing can create unique visual effects that enhance the final design. By utilizing multiple layers of transfers, printers can achieve depth and dimension that truly stand out. Learning these advanced DTF transfer techniques can set you apart in a competitive market, allowing you to offer one-of-a-kind designs that showcase your artistic flair.

Post-Transfer Care for DTF Designs

Following the proper care steps post-transfer is essential to maintain the integrity of DTF transfers. Once the transfer is completed, it’s crucial to allow garments to cool before peeling the film off. This step ensures that the design has fully adhered to the fabric, preventing any lifting or distressing. Following this, washing instructions play a significant role in preserving the design; washing garments inside out in cold water helps prevent fading and peeling.

In addition to washing, it’s also advisable to avoid harsh detergents or fabric softeners that might compromise the durability of the DTF transfer. Educating customers about proper garment care can lead to longer-lasting products and higher customer satisfaction. The care you take post-transfer directly impacts the longevity of your designs, making it a vital part of the printing process.

The Future of DTF Printing Innovations

The future of DTF printing is poised for continuous innovation, driven by advancements in technology and materials. Recent developments in ink formulations are enhancing color vibrancy and durability, allowing print makers to produce high-quality results with greater ease. New technologies are also emerging that promise to reduce curing times, making the printing process faster and more efficient for businesses looking to scale operations without sacrificing quality.

Moreover, the expansion of online communities and platforms for sharing insights and experiences is an exciting trend in the DTF printing industry. These virtual spaces are rich resources, enabling printers of all skill levels to educate themselves on the latest techniques and technologies. Engaging with these communities can foster collaboration and inspire creativity, ensuring that those involved in DTF printing remain at the forefront of industry trends.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs on a special film that is then applied to fabric using heat and pressure. This innovative DTF printing technique produces vibrant and durable designs that are wash-resistant, making them ideal for custom fabric applications.

What materials are best for DTF printing?

For successful DTF transfers, using high-quality materials is essential. Invest in premium DTF films and inks from reputable brands like Avery Dennison or Stahls’. Quality materials ensure vibrant color reproduction and strong adhesion to fabrics, greatly improving the overall print quality.

How should I prepare artwork for DTF transfers?

When preparing artwork for DTF printing, it is crucial to use graphic design software like Adobe Illustrator or Photoshop. Create your designs in vector format if possible, and set your artwork resolution to 300 DPI for optimal print quality. Meticulous preparation leads to stunning results in DTF transfers.

What are the ideal heat press settings for applying DTF transfers?

To master DTF transfer techniques, preheat your heat press to a temperature range of 320°F to 330°F and press the design for 15-20 seconds. Applying firm pressure is key to ensuring proper adherence of the DTF transfer to the fabric without damaging the print.

What post-transfer care is recommended for DTF prints?

After completing a DTF transfer, allow the garment to cool before peeling off the film. For maintaining vibrant prints, wash the garment inside out in cold water. Following these post-transfer care guidelines is vital to prevent fading and peeling of your custom DTF designs.

What advancements are being made in DTF printing technology?

Recent developments in DTF printing technology have enhanced color vibrancy and wash durability of designs. Innovations in ink technology lead to faster drying times and improved efficiency, making it easier for both amateur and professional print makers to create high-quality DTF transfers.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF (Direct-to-Film) transfers offer durable and vibrant designs for fabric, using specialized film and heat for application. |

| Quality Materials | Using premium DTF films and inks is crucial for vibrant colors and good adherence. |

| Artwork Preparation | Prepare artwork with vector files in programs like Adobe Illustrator or Photoshop at 300 DPI. |

| Optimized Printing Settings | Always select the highest printing quality, and use correct profiles for films and inks. |

| Heat Press Techniques | Preheat to 320°F-330°F, press for 15-20 seconds with firm pressure. |

| Post-Transfer Care | Allow cooling before peeling film; wash inside out in cold water. |

| Innovations in DTF | Recent developments include better ink technology and quicker curing processes, improving efficiency. |

| Community Resources | Online communities provide valuable tips and experiences, enhancing printing skills. |

Summary

DTF Transfers are revolutionizing the printing landscape, providing a means to achieve vibrant, durable designs on fabric effortlessly. As you embark on this design journey, it’s essential to focus on quality materials, meticulous artwork preparation, and optimizing your printing settings for the best results. Mastering the techniques of heat pressing and following post-transfer care are critical steps to ensure longevity and clarity in your designs. Furthermore, staying updated on the latest advancements and tapping into community resources can significantly enhance your skills. With dedication and practice, DTF transfers will open a world of possibilities for creating stunning designs that captivate audiences and meet professional standards.