DTF Transfers, or Direct to Film transfers, have quickly gained popularity as a revolutionary method in the fabric printing sector. This advanced printing technology enables vivid designs to be seamlessly printed onto a variety of textiles with remarkable quality and efficiency. DTF printing advantages over traditional methods include better precision, flexibility, and affordability, making it a preferred choice for both small-scale custom apparel printing and larger manufacturing operations. As the demand for sustainable printing practices rises, DTF transfers provide an eco-friendly alternative by minimizing waste and using less harmful chemicals in the printing process. In this article, we’ll delve into the transformative impact of DTF technology on the printing industry and explore its myriad benefits for businesses and consumers alike.

The world of fabric decoration is evolving rapidly, with Direct to Film (DTF) technology leading the charge. This innovative approach to custom fabric printing offers a variety of advantages, such as superior print quality and compatibility with different materials. With the rise of sustainable printing trends, many businesses are looking for alternatives to traditional methods, and DTF presents itself as an ideal solution. This technique not only thrives in durability and detail but also addresses environmental concerns by utilizing fewer resources than conventional printing processes. As we unpack the potentials of this advanced fabric printing technology, it becomes clear that DTF Transfers are set to redefine the landscape of custom apparel production.

Understanding DTF Transfers: The Future of Fabric Printing

DTF transfers, or Direct to Film printing, represent a revolutionary shift in the landscape of fabric printing technology. This process involves printing on a special film before applying it to the fabric, allowing for remarkable detail and durability in the final product. With the capacity to cater to various materials such as cotton, polyester, and blends, DTF printing has become increasingly essential for custom apparel businesses looking to meet diverse consumer demands. Understanding this process is crucial for any business aiming to stay competitive in a quickly evolving market.

One of the standout features of DTF printing is its compatibility with a wide range of textiles, giving producers the flexibility to target various segments in the apparel industry. As businesses look to diversify their offerings, the ability to produce high-quality prints across different fabrics without investing in multiple systems can significantly enhance operational efficiency. Furthermore, the quality output produced by DTF technology, characterized by vibrant colors and intricate designs, positions it as a preferred choice for fashion-forward consumers.

The Advantages of DTF Printing Over Traditional Methods

DTF printing boasts numerous advantages that set it apart from traditional printing methods such as screen printing or direct-to-garment (DTG) printing. One major benefit is its speed and efficiency; it enables quicker turnaround times on production runs, making it ideal for businesses that operate in fast-paced market environments. Furthermore, the quality attained through DTF printing is exceptional, yielding intricate designs that resonate with customers looking for bespoke fashion statements.

Moreover, DTF technology offers a cost-effective solution for both small startups and established enterprises. With lower setup costs and reduced ink consumption compared to traditional methods, businesses can increase their profit margins while offering competitive pricing to customers. As many industries shift towards online retail, the ability to deliver custom orders swiftly through DTF printing opens new avenues for businesses to connect with consumers.

Exploring the Workflow Efficiency of DTF Transfers

The efficiency of the workflow in DTF printing translates into considerable time savings for businesses. Unlike conventional methods that require extensive setup and manual labor, DTF transfers streamline the entire process, allowing for rapid adjustments to design and layering. This capability not only enhances a company’s ability to respond to market trends but also positions them favorably against competitors stuck with slower methodologies.

Additionally, with the integration of modern technology in the DTF printing process, businesses can automate their production further, leading to improved accuracy and consistency in prints. This enhanced workflow promotes scalability, enabling companies to take on larger orders without compromising on quality. Efficiency is critical in today’s retail landscape, and DTF printing cultivates a production environment ripe for innovation.

Sustainability in DTF Printing: A Greener Choice

As environmental consciousness continues to grow among consumers, the sustainability aspects of DTF printing are of great importance. DTF technology uses significantly less water and reduces the use of harmful chemicals compared to traditional printing techniques. By adopting eco-friendlier practices, businesses can appeal to a broader audience who prioritize sustainability in their purchasing decisions.

Moreover, the ongoing advancements in DTF technology aim to decrease waste and optimize energy consumption during production. This commitment to sustainable practices strengthens a brand’s position in the market as environmentally responsible. By promoting DTF printing as a greener choice, businesses not only contribute positively to the ecosystem but also enhance their brand loyalty among eco-conscious consumers.

Market Growth and Prospects for DTF Printing

The market for DTF printing is projected for significant growth as demand for high-quality custom apparel continues to rise. Companies that integrate DTF technology into their production capabilities are likely to thrive as consumer preferences shift toward personalized and unique designs. The versatility of DTF printing positions it firmly at the forefront of the future of fabric printing, attracting interest from a diverse range of industries.

Investment in advanced DTF printing technologies promises lower barriers to entry for new businesses, fostering competition and innovation within the textile industry. As consumers seek unique and quality products, the response from DTF printing technology could reshape how businesses approach fabric decoration, leading to more dynamic industry practices and offerings.

Embracing DTF Technology for Competitive Advantage

Businesses that embrace DTF printing stand to gain a competitive advantage in the crowded custom apparel market. By adopting this innovative technology, companies can produce high-impact designs that meet the increasing demands of consumers for uniqueness and quality. As the fashion industry becomes more saturated with options, standing out through superior print quality becomes crucial.

Furthermore, the adaptability of DTF printing allows businesses to pivot quickly in response to changing trends and consumer preferences, thereby enhancing customer satisfaction. With the combination of superior print techniques, sustainability, and cost efficiency, DTF transfers position businesses to not only meet but exceed market expectations, ultimately leading to increased customer loyalty and brand recognition.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

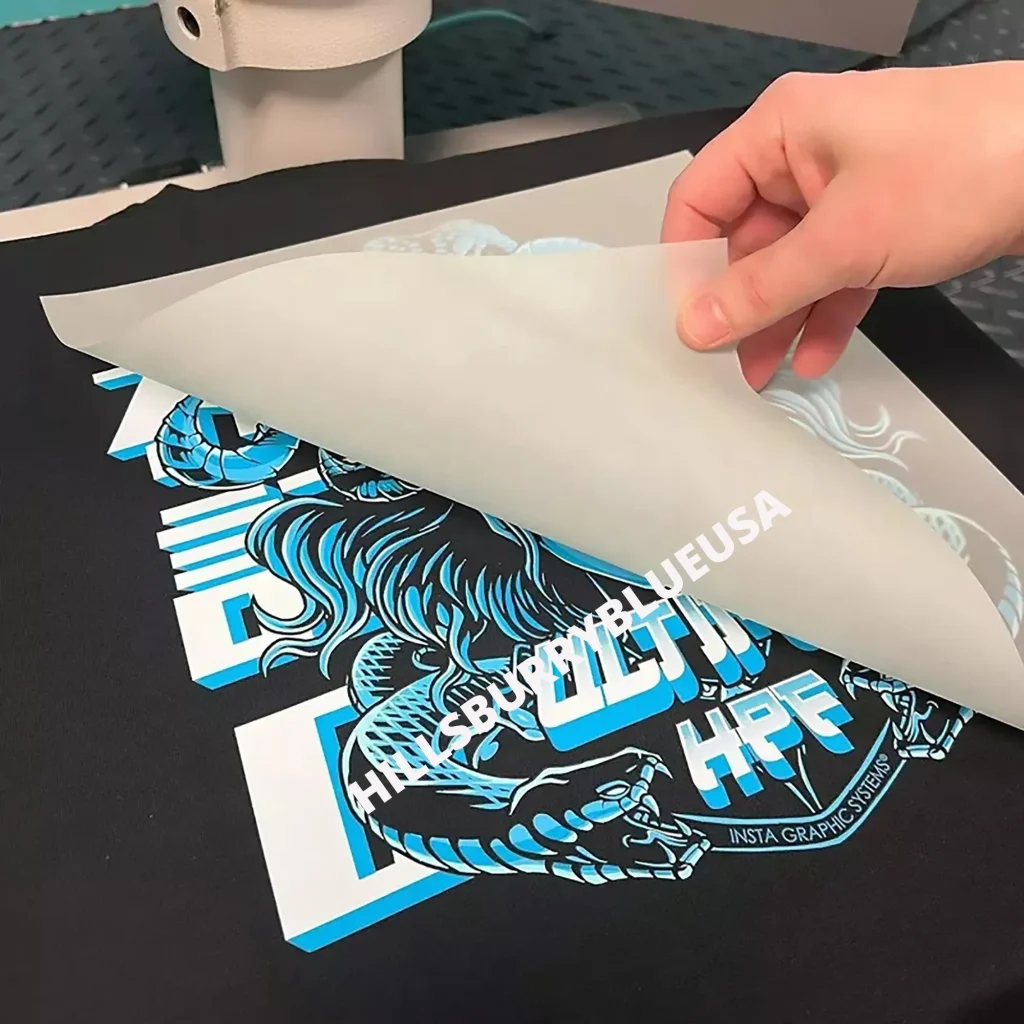

DTF transfers, or Direct to Film transfers, involve a process where images are printed onto a special film and then transferred onto various fabrics using a heat press. This method allows for high-quality, detailed designs, making it ideal for custom apparel printing, as it works well with various materials including cotton and polyester.

What are the advantages of DTF printing compared to traditional printing methods?

DTF printing offers several advantages over traditional methods, including exceptional print quality with vibrant colors, compatibility with a wide range of fabrics, and cost-effectiveness which is vital for small businesses. Additionally, its efficient workflow enables quicker turnarounds, meeting the fast-paced demands of the market.

How does DTF printing technology ensure sustainability in fabric printing?

DTF printing technology is considered more sustainable than traditional methods due to its lower water consumption and reduced use of harmful chemicals. Ongoing advancements in DTF processes also focus on minimizing waste and energy use, aligning with eco-friendly practices in the printing industry.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are versatile and can be used on a variety of fabric types, including cotton, polyester, and blends. This compatibility allows businesses to cater to diverse customer requests and enhances their custom apparel offerings.

What is the impact of DTF transfers on the printing market landscape?

DTF transfers are revolutionizing the printing market by providing high-quality, cost-efficient, and flexible solutions. As more businesses adopt this technology, the demand for DTF printing solutions is expected to grow, leading to increased competition and innovation in the industry.

What factors contribute to the cost-effectiveness of DTF printing?

The cost-effectiveness of DTF printing arises from advancements in technology that have significantly reduced the cost per print. This benefit allows small businesses to enter the custom apparel market without high initial investments, promoting growth and competition in the fabric printing sector.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A method where designs are printed onto a film and then transferred to fabric with a heat press, allowing for high-quality prints on various materials. |

| Quality and Detail | Offers vibrant colors and sharp details ideal for custom apparel, meeting customer demands for high-quality prints. |

| Material Compatibility | Compatible with a range of fabrics including cotton and synthetics, providing businesses with versatile options to meet customer preferences. |

| Cost-Effectiveness | Cost per print has decreased significantly, making it accessible for startups and small businesses, fostering increased competition in the market. |

| Workflow Efficiency | Simplifies production processes allowing for quick adjustments and fast responses to market demands, ideal for fast-paced retail. |

| Environmental Impact | Considered more eco-friendly than traditional methods, using less water and chemicals, with ongoing improvements in sustainability. |

| Market Growth and Future Prospects | Significant market growth expected as more businesses adopt DTF technology, driven by its advantages in quality and cost-efficient solutions. |

Summary

DTF Transfers are transforming the printing industry with innovative strategies that emphasize high-quality, flexible, and sustainable production methods. By harnessing the advanced technology of Direct to Film printing, businesses can effectively meet diverse customer demands while minimizing costs. This remarkable evolution is set to reshape the landscape of fabric printing, enabling creators and manufacturers to produce intricate designs with ease and efficiency.