DTF transfers, short for Direct-to-Film printing, represent a groundbreaking shift in the custom t-shirt printing landscape, allowing businesses to create stunning and durable designs with ease. This innovative technology eliminates many limitations associated with traditional methods like screen printing, making it accessible to small businesses and home entrepreneurs eager to enter the custom apparel market. With remarkable advantages, including cost-effectiveness and rapid turnaround times, DTF printing is quickly becoming a favored choice among those looking to make their mark in the industry. As we delve deeper into the world of DTF transfers, you’ll discover how this advancement is reshaping the market and principles of custom design, offering unparalleled possibilities for creativity and expression. Whether you’re a seasoned professional or a newcomer, understanding the impact of DTF printing can empower you to navigate the dynamic apparel landscape confidently.

Direct-to-Film (DTF) printing is often hailed as a revolutionary technique in the realm of customized garment design. This method utilizes advanced film technology that simplifies the transfer of intricate artwork onto fabrics, leading to vibrant and long-lasting results. As screen printing alternatives gain popularity, DTF transfers are at the forefront due to their ability to provide quality prints while minimizing the start-up investment typically required for traditional techniques. In an industry where customization is key, this technology not only enhances production efficiency but also democratizes the custom apparel market, allowing more creators to realize their visions. The emergence of DTF printing signifies a pivotal moment in the evolution of personalized fashion, shaping the future of how we wear and express our individuality.

Understanding Direct-to-Film Printing

Direct-to-Film (DTF) printing is revolutionizing the way custom t-shirts are produced, enabling creators to print intricate designs onto a special film that is then transferred to fabric. Unlike conventional screen printing methods, DTF printing involves a simpler process that cuts down on the necessary setup time and equipment costs. Small businesses and individual entrepreneurs can now break into the custom apparel market without the hefty upfront investment that often accompanies traditional printing methods.

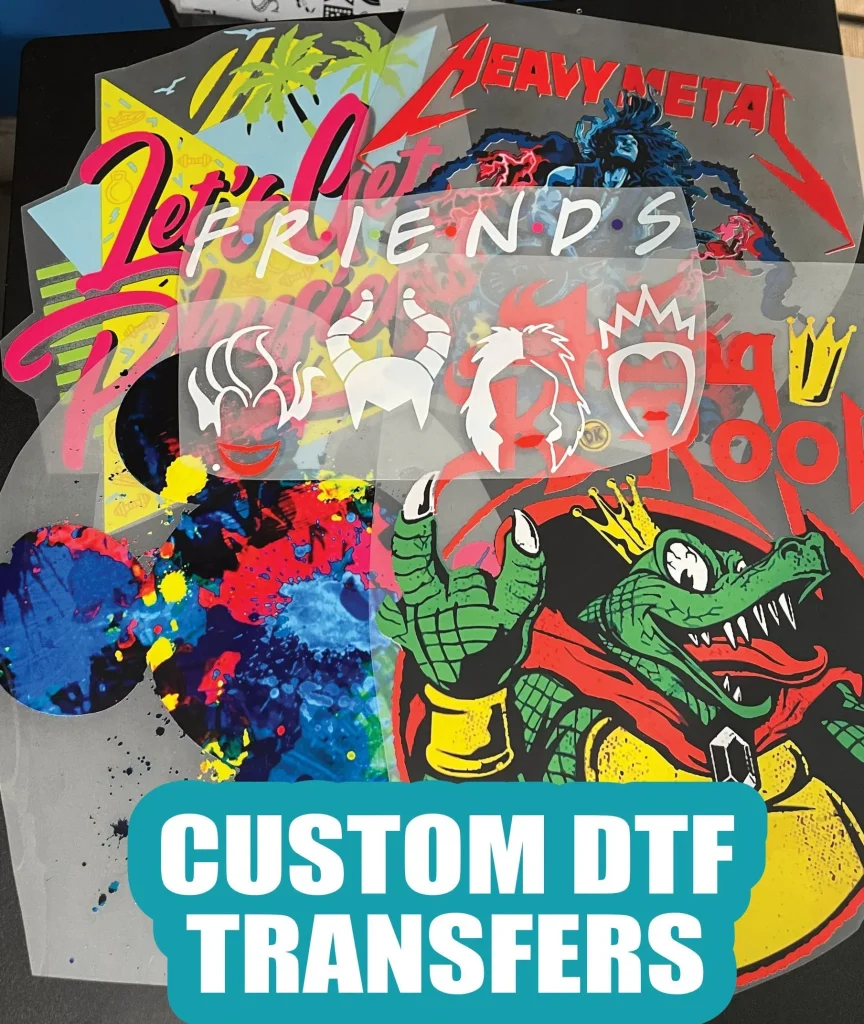

The versatility of DTF printing allows for a wide range of designs, from detailed graphics to vibrant color patterns, seamlessly integrating innovation into the custom apparel landscape. As this technology continues to evolve, it is anticipated that more creators will adopt DTF transfers, facilitating a shift toward more personalized and unique products, which is becoming increasingly appealing to consumers.

The Rise of DTF Transfers in the Custom Apparel Market

As consumer demand for personalized and unique clothing experiences grows, DTF transfers have surged in popularity. Businesses are recognizing the advantages of using DTF technology, which enables them to quickly produce vibrant designs that are durable and appealing. This trend has paved the way for a new wave of entrepreneurs who can establish their clothing lines without the constraints of traditional printing techniques.

The emergence of DTF printing has created opportunities for small businesses and home-based creators to thrive, leading to a more diverse array of styles available on the market. By offering creators rapid production capabilities and design flexibility, DTF transfers are reshaping the landscape of the custom t-shirt industry.

Advantages of DTF Transfers Over Traditional Screen Printing

One of the standout advantages of DTF transfers is their cost-effectiveness compared to traditional screen printing. DTF technology eliminates the need for extensive setup, allowing new brands to enter the custom apparel market with lower financial barriers. This accessibility has empowered more entrepreneurs to launch unique clothing designs that cater to niche markets, driving creativity and innovation.

In addition to cost savings, DTF printing boasts rapid turnaround times. Businesses utilizing DTF technology can quickly respond to trends and consumer demands, thus streamlining inventory management. This efficiency not only meets customer needs in real-time but also enhances operational productivity, making DTF printing a preferred choice for many entrepreneurs in the custom apparel market.

Quality and Durability of DTF Prints

DTF transfers produce high-quality prints that are both vibrant and durable, setting them apart from other printing methods. The technology used in DTF printing allows for detailed designs and bright colors that resist fading over time, even after multiple washes. This quality ensures customer satisfaction as garments maintain their appearance, increasing the likelihood of repeat purchases.

This durability is particularly essential in the custom apparel industry, where consumers seek products that not only look good but also withstand regular wear. As brands focus on building customer loyalty, high-quality DTF prints will continue to be a vital factor in promoting a positive brand image in the saturated market.

Sustainable Practices in DTF Printing

As the custom t-shirt industry evolves, sustainability has become a critical consideration for many brands. DTF printing offers a more eco-friendly alternative by significantly reducing waste associated with traditional bulk printing methods. By allowing for short production runs, businesses can produce only what is needed, minimizing the risk of overstock and unnecessary waste.

Furthermore, DTF transfers enable brands to adopt sustainable practices without compromising on quality or style. This alignment of modern innovation with environmental responsibility resonates with consumers who are increasingly supportive of brands that prioritize sustainability, thereby enhancing brand loyalty and market presence.

Future Trends in DTF Printing Technology

The future of DTF printing is bright, with continuous improvements in technology and techniques designed to enhance the printing process. Innovation is expected to lead to higher printing efficiencies, further reducing costs for businesses while maintaining high-quality outputs. As technology advances, it will likely introduce new materials and inks that provide even greater durability and color vibrancy.

Moreover, as more businesses recognize the benefits of DTF transfers, the competition in the custom apparel market will grow, leading to further advancements. This evolution is not only beneficial for businesses but also encourages creativity and innovation in design, ultimately enriching the consumer experience in the custom t-shirt industry.

Frequently Asked Questions

What are DTF transfers in custom t-shirt printing?

DTF transfers, or Direct-to-Film transfers, are a revolutionary printing technology used in custom t-shirt printing. This method involves printing high-quality designs onto a special film, which is then transferred onto fabric surfaces. Unlike traditional screen printing, DTF transfers offer a cost-effective, quick, and flexible solution for creating custom apparel.

What are the advantages of DTF printing over traditional screen printing?

DTF printing has several key advantages over traditional screen printing. It is cost-effective, requires lower initial investments, and provides faster turnaround times. Additionally, DTF transfers produce high-quality prints that are vibrantly colored and durable, maintaining their appearance through multiple washes, making them ideal for custom apparel.

How does DTF printing support new entrepreneurs in the custom apparel market?

DTF printing empowers new entrepreneurs by lowering financial barriers to entry in the custom apparel market. With minimal upfront costs compared to traditional screen printing, aspiring clothing brands can easily start their businesses using DTF transfers, enabling them to offer unique designs without substantial overhead.

Can DTF transfers be used for bulk production in custom apparel?

Yes, DTF transfers can be utilized for bulk production in custom apparel. This printing method allows for efficient handling of larger orders while minimizing waste, as businesses can produce only the quantities needed. This is particularly beneficial for responding to market trends quickly.

Why are DTF transfers becoming popular in the custom t-shirt industry?

DTF transfers are gaining popularity in the custom t-shirt industry due to their accessibility and versatility. As small businesses and home-based creators adopt this technology, they can produce complex designs economically and efficiently, which meets the growing consumer demand for personalized and unique apparel.

How does DTF printing contribute to sustainability in the fashion industry?

DTF printing contributes to sustainability in the fashion industry by reducing waste associated with bulk production runs. It allows businesses to produce smaller batches, thereby minimizing overstock and promoting more eco-friendly practices. This approach encourages responsible manufacturing in the custom apparel market.

| Key Feature | Description |

|---|---|

| DTF Transfers Overview | A printing technology that allows designs to be printed on special film for transfer onto fabrics. |

| Cost-effectiveness | Lower startup costs compared to traditional screen printing, making it accessible for new brands. |

| Quick Turnaround Times | Faster production capabilities for more responsive inventory management. |

| High-Quality Prints | Produces vibrant and durable designs that can withstand multiple washes. |

| Market Growth | Increasing adoption among small businesses reflecting a shift in the custom apparel landscape. |

Summary

DTF transfers are transforming the custom t-shirt industry by providing an innovative and cost-effective solution for producing high-quality apparel. This technology not only reduces the financial barriers for new entrants but also enhances production speed and print quality. As more entrepreneurs adopt DTF transfers, we witness a diversification of designs and styles available in the market. This revolution is encouraging creativity and sustainability within the fashion industry, pointing towards a promising future for custom apparel production.