DTF transfers, or Direct-to-Film transfers, are rapidly revolutionizing the fabric printing landscape, offering an efficient and vibrant solution for custom fabric printing. This innovative technique utilizes specialized PET film to print detailed designs, which can then be transferred onto various materials through a simple heat press process. One of the notable advantages of DTF printing is its versatility, as it allows for stunning results on both natural and synthetic fibers, catering to a wide array of applications. Whether you’re looking to create unique apparel or promote your brand with custom designs, understanding what DTF printing is and the processes involved can greatly enhance your creative endeavors. Join us as we explore the world of DTF transfers, examining their benefits and diverse uses in modern fabric printing.

When discussing innovative fabric printing solutions, terms like film transfers and digital textile printing frequently arise. Direct-to-Film technology, often hailed for its efficiency and quality, enables designers and businesses to produce vivid and resilient prints on an assortment of materials. The DTF printing method stands out for its ability to preserve intricate designs while allowing for rapid production, making it appealing to both professional creators and enthusiastic hobbyists. With the growing demand for personalized fabric applications, the options provided by DTF transfer techniques are paving the way for new trends in custom apparel and promotional merchandise. Explore how this dynamic printing approach can transform your creative projects today.

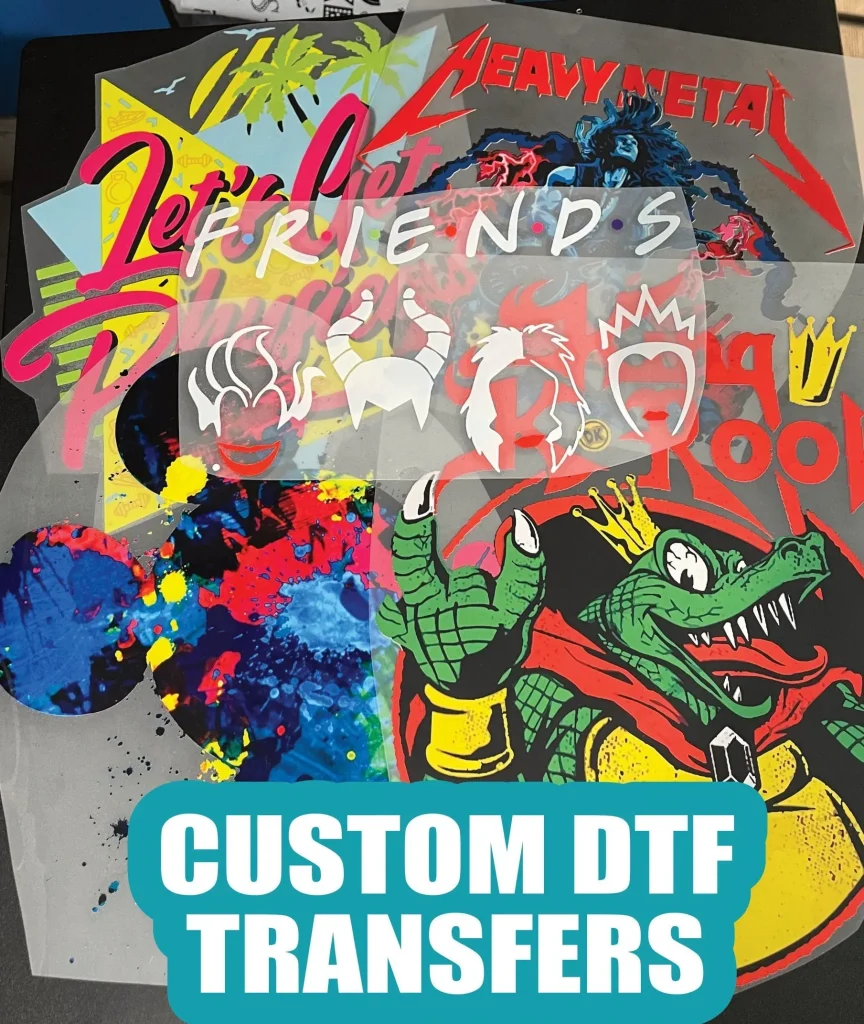

Understanding DTF Transfers in Fabric Printing

DTF transfers, or Direct-to-Film transfers, are a relatively new and innovative approach to fabric printing that allows for the transfer of vibrant and high-quality images directly onto fabrics. By using a specialized PET film, DTF printing streamlines the design process, making it accessible for both beginners and seasoned professionals in custom fabric printing. Unlike traditional printing methods which require significant setup and investment, DTF transfers enable users to create designs quickly and apply them to a variety of materials with ease.

The beauty of DTF transfers lies in their versatility. They can be applied to a wide range of fabric types including cotton, polyester, and blended materials, making them suitable for almost any project. This adaptability is particularly advantageous for designers who want to experiment with different textiles or for businesses that need to cater to diverse customer preferences. Plus, the ability to prepare prints in advance adds a level of convenience that further enhances their appeal.

The Step-by-Step DTF Printing Process

The DTF printing process is straightforward yet highly effective, ensuring that users can produce stunning designs with minimal hassle. First, the journey begins with the creation of a digital design, where designers can unleash their creativity and develop unique graphics tailored to their vision. After finalizing the design, it is printed onto a PET film with high-quality inks that capture vibrant colors. This step is crucial as it sets the tone for the final product.

Once the ink is dried, the printed film is coated with a specialized adhesive powder, a crucial component that allows the design to bond effectively to the fabric during the heat transfer process. The final step involves using a heat press to apply the film onto the chosen fabric. This heat activation not only affixes the design but also provides durability, ensuring that the prints withstand washing and wear over time.

Exploring the Benefits of DTF Printing

The advantages of DTF printing are compelling and make it a standout option among various fabric printing methods. One primary benefit is its versatility; DTF can be applied to a variety of materials without the need for complex machinery that is often associated with other printing techniques like screen printing. This eliminates barriers for small businesses and individual creators who may not have the means to invest heavily in specialized equipment.

Moreover, DTF printing enables the production of high-quality, detailed designs that can endure multiple washes without fading. This durability is especially important for custom apparel, where the quality of print directly impacts customer satisfaction. Additionally, DTF transfers are known for being cost-effective, allowing businesses to increase their output without incurring high costs.

The Impact of DTF Printing on the Fabric Industry

DTF printing’s introduction into the fabric printing landscape marks a pivotal shift, transforming how designers and businesses approach custom fabric applications. The straightforward nature of DTF allows more individuals to engage in fabric design without the need for significant investment, essentially democratizing the art of fabric printing. This has led to a surge in creativity and innovation, giving rise to a new generation of creators who can experiment freely.

Furthermore, the low barrier to entry encourages budding entrepreneurs to explore startup ventures in the custom apparel market. The ability to create stunning and durable designs using DTF transfers opens up numerous opportunities for small businesses to capitalize on trends and consumer preferences while maintaining quality and efficiency.

Wide-Ranging Applications of DTF Printing

The applications of DTF printing are vast, extending across various industries and creative projects. From custom garments such as t-shirts, sweatshirts, and activewear, to promotional items like tote bags, hats, and giveaways, the DTF printing process adapts seamlessly to different needs. Businesses can leverage this technology to create professional-grade merchandise that resonates with customers, allowing for a tailored branding experience that stands out in a crowded marketplace.

Additionally, DTF printing caters to personal projects, enabling hobbyists to experiment with custom designs on fabrics without facing hefty costs. Whether it’s crafting unique pieces for family events or designing merchandise for small community initiatives, the flexibility of DTF transfers empowers creators to bring their visions to life without extensive financial commitments.

Why Choose DTF Transfers for Your Printing Needs

Choosing DTF transfers for your printing needs comes with numerous advantages that enhance both the practical and aesthetic elements of fabric production. DTF printing is particularly favored due to its ability to produce high-quality prints with vibrant colors that capture the essence of detailed designs. This high level of print fidelity is essential for designers aiming to make a striking visual impact on their target audience.

Furthermore, the ease of use associated with printing DTF transfers streamlines operations for businesses and creators alike. Since prints can be prepared ahead of time and stored, this technique not only increases workflow efficiency but also helps meet varying demand levels without the usual overhead of traditional printing methods. DTF transfers thus represent an optimal choice for anyone looking to diversify their fabric printing capabilities.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a cutting-edge method that involves printing vibrant designs onto a specialized PET film. The film is then coated with an adhesive powder and heat-pressed onto fabrics, allowing for high-quality transfers onto various materials. This process enhances efficiency by allowing prints to be prepared in advance for later application, making it ideal for custom fabric printing.

What are the main advantages of DTF printing?

DTF printing offers numerous advantages, including versatility across different fabric types, high-quality vibrant prints, cost-effectiveness, and improved production efficiency. It allows small businesses and individual creators to produce professional-looking custom garments without expensive setup costs, all while being environmentally friendly with non-toxic materials.

What types of fabrics can benefit from DTF transfers?

DTF transfers work exceptionally well on a variety of fabrics, including natural fibers like cotton and synthetic blends such as polyester. This versatility makes DTF printing suitable for a wide range of applications, from custom apparel to promotional items.

What applications are ideal for DTF transfers?

DTF transfers can be used in multiple applications ranging from custom garments like t-shirts and hoodies, to promotional items such as tote bags and hats. Hobbyists can also utilize DTF for creative personal projects, showcasing its broad adaptability for both personal and commercial use.

How does the DTF printing process differ from traditional fabric printing methods?

Unlike traditional methods like screen printing, which require extensive setup and specialized equipment, DTF printing simplifies the process. It allows for pre-printed designs on film, which can be quickly and easily applied to fabrics, offering a cost-effective and less cumbersome alternative for custom fabric printing.

Is DTF printing an eco-friendly option for custom fabric projects?

Yes, DTF printing can be considered eco-friendly as many of the materials used, including inks and adhesives, are often non-toxic. This makes DTF printing an appealing choice for environmentally conscious consumers looking for sustainable practices in custom fabric printing.

| Key Point | Description |

|---|---|

| What is DTF Printing? | DTF printing transfers designs onto fabrics using PET film, high-quality inks, and adhesive powder. |

| The DTF Printing Process | Involves design creation, printing on film, applying adhesive powder, and heat pressing onto fabric. |

| Advantages of DTF Printing | Offers versatility, quality prints, cost-effectiveness, efficiency, and eco-friendly options. |

| Applications of DTF Printing | Used for custom garments, promotional items, and personal projects across various sectors. |

Summary

DTF transfers represent a groundbreaking advancement in the world of fabric printing, combining diversity with efficiency. This innovative technique allows for high-quality, vivid prints that can adhere to a multitude of fabric types, making DTF printing an exceptional choice for custom apparel and personal projects. By streamlining the production process and reducing overhead costs, DTF printing has opened new avenues for both small businesses and passionate hobbyists looking to create unique, personalized items. The resulting versatility and cost-effectiveness of DTF transfers empower creators and designers to embrace their artistic vision while catering to a wider audience. As the fabric printing landscape evolves, DTF transfers are poised to lead the charge in transforming how we approach custom fabric design.