In the realm of custom apparel printing, DTF transfers have emerged as a revolutionary method that bridges the gap between digital innovation and traditional craftsmanship. With DTF printing, businesses can harness the power of direct-to-film transfers for vibrant and detailed designs that breathe life into their products. The benefits of DTF transfers are numerous, including their adaptability to various fabrics and the ability to produce high-quality images that withstand the test of time. This guide delves into DTF technology, highlighting the advantages it brings to the table, including cost-efficiency and quick turnaround times, making it an invaluable resource for any custom apparel business. Join us as we explore the endless possibilities offered by DTF transfers and how they can elevate your creative designs.

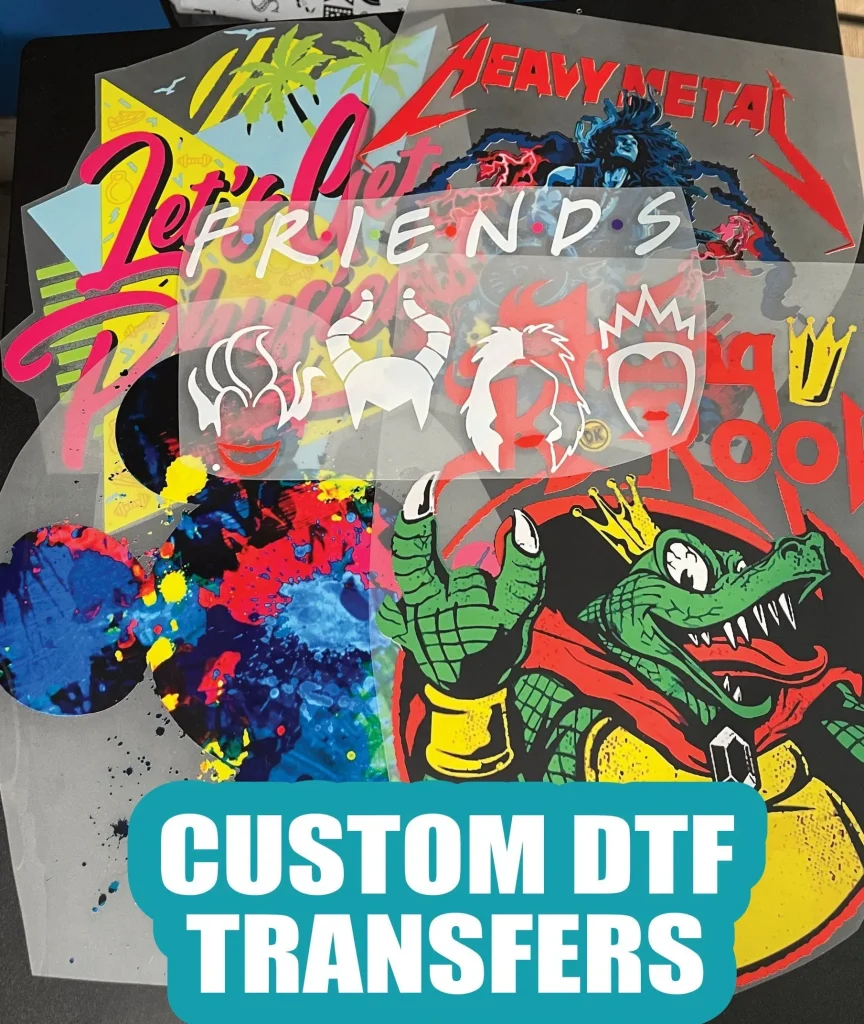

Direct-to-Film (DTF) technology, also known as direct-to-film transfers, is transforming the landscape of custom garment printing by providing an efficient and versatile solution for creating eye-catching apparel. This modern printing technique allows designs to be printed directly onto a specialized film, which is then heat-pressed onto fabric, enabling businesses to produce stunning visual effects on various material types. The charm of this method lies in its ability to cater to both large orders and smaller, custom requests, making it a popular choice among printers looking to expand their service offerings. The detailed prints delivered by DTF technology not only meet high-quality standards but also resonate with customer demands for durability and visual appeal. As we delve deeper into the realm of DTF transfers, we will uncover their key benefits and applications that set them apart from traditional printing methods.

Understanding the DTF Printing Process

The DTF (Direct-to-Film) printing process involves printing designs onto a special transfer film which is then applied to fabric using heat and pressure. This method is distinct from other techniques such as direct-to-garment (DTG) and screen printing, primarily because it allows a wide range of fabrics to be utilized, including cotton, polyester, and blends. The process begins with a digital design being printed onto a PET film using specially formulated inks that are designed to adhere well to both the film and the textile.

After printing, the film is coated with a layer of adhesive powder, which is then cured. When the film is heated and pressed onto the fabric, the adhesive activates and bonds the ink to the material. The result is a vibrant and durable design that is not only visually appealing but also resistant to fading and cracking. This methodology also allows for intricate detailing and a variety of colors, making it an ideal choice for custom apparel printing.

The Advantages of Using DTF Transfers for Custom Apparel

DTF transfers offer several advantages that make them a go-to solution for custom apparel. Firstly, they provide unmatched vibrancy and quality, allowing designs to maintain their color intensity even after multiple washes. Unlike traditional printing methods, DTF technology ensures that designs are sharp and detailed, producing a professional finish that meets customer expectations. Businesses utilizing DTF transfers often report increased customer satisfaction and repeat orders due to the high-quality output.

Additionally, the versatility of DTF printing cannot be overstated. This technology allows transfers to be applied to a variety of fabrics, expanding the array of products that can be offered. Whether working with 100% cotton, stretchy polyester, or blended fabrics, DTF transfers facilitate creativity and customization in product offerings. These benefits make DTF an attractive option for businesses looking to differentiate themselves in the competitive custom apparel market.

DTF Technology: A Game-Changer in the Apparel Industry

DTF technology has revolutionized the custom apparel landscape, offering a seamless blend of digital printing and traditional methods. This innovative approach not only simplifies the printing process but also enhances the quality and efficiency of production. As more businesses embrace DTF, the range of available materials and inks continues to expand, paving the way for even more innovative designs and applications.

Furthermore, DTF printing allows for quick turnaround times, making it ideal for businesses that require fast service levels. This efficiency is crucial in an era where customers expect prompt delivery of personalized products. By incorporating DTF technology into their operations, custom apparel businesses can improve their responsiveness to market demands while maintaining high quality.

Cost-Effectiveness of DTF Transfers for Small Operators

For small businesses and startups, the cost-effectiveness of DTF transfers makes it an appealing choice. Unlike traditional screen printing, which often requires a significant upfront investment for setup and equipment, DTF printing involves relatively low startup costs. Only a DTF printer and a heat press are needed, allowing new entrants in the custom apparel market to begin operations without a substantial financial burden.

This cost-efficient printing solution not only benefits small operators but also opens up new opportunities for creativity. Businesses can afford to experiment with limited edition runs and custom designs without worrying about excessive costs. As a result, this method encourages innovation and creativity, enabling entrepreneurs to develop unique products that resonate with their target markets.

Recent Trends in DTF Printing Technology

The DTF printing landscape is rapidly evolving, with technological advancements making this method more efficient and sustainable. Recent developments in DTF printing technology have led to improved printer capabilities, and the introduction of higher quality and eco-friendly inks. These improvements enhance adhesion, durability, and washability of the prints, making DTF transfers even more appealing for custom apparel producers.

Moreover, with sustainability taking center stage in manufacturing processes, DTF transfers align well with these trends. Many DTF printers are now designed to minimize waste, adhering to eco-friendly standards by reducing material usage and conserving energy. As businesses strive to adopt more sustainable practices, DTF technology offers an effective solution for producing high-quality apparel while minimizing environmental impact.

Maximizing Your Business Potential with DTF Transfers

Incorporating DTF transfers into your business strategy can significantly enhance your market offerings. By leveraging the superior quality, versatility, and efficiency of DTF technology, businesses can cater to a broader customer base and meet diverse demands. As customers increasingly seek customization and personalization, mastering DTF printing allows businesses to position themselves as leaders in the custom apparel space.

Furthermore, DTF transfers enable businesses to expand beyond traditional boundaries. With their ability to print on varied fabrics and surfaces, companies can explore new markets, from promotional items to fashion apparel. By staying ahead of industry trends and embracing innovative printing solutions such as DTF, businesses can ensure sustained growth and a competitive edge in the rapidly evolving landscape of custom apparel.

Frequently Asked Questions

What are the main benefits of DTF transfers for custom apparel printing?

DTF transfers offer several benefits for custom apparel printing, including high-quality prints with vibrant colors, versatility across various fabric types (like polyester and nylon), cost-effectiveness for small order sizes, ease of use with simpler equipment requirements, and fast turnaround times to meet customer demands.

How does DTF printing differ from traditional screen printing?

Unlike traditional screen printing, DTF printing uses a special film to transfer designs onto fabric, which allows for greater flexibility in materials and faster production times. DTF is more suitable for short runs, eliminating costly setups required by screen printing, and it provides vibrant, durable prints ideal for custom apparel.

Can DTF technology be used on multiple fabric types?

Yes, one of the standout features of DTF technology is its versatility; it can be applied to a wide range of fabric types including cotton, polyester, nylon, and various blends. This flexibility makes it an excellent choice for custom apparel businesses looking to expand their product offerings.

What equipment is necessary for starting DTF transfers?

To get started with DTF transfers, you typically need a DTF printer and a heat press. The operational complexity is lower than traditional screen printing, making it accessible for small businesses and startups aiming to enter the custom apparel market.

How quickly can DTF transfers be produced compared to other printing methods?

DTF transfers can be produced rapidly, allowing businesses to fulfill orders quickly and efficiently. This speed makes DTF technology especially appealing for businesses facing tight deadlines for events or promotional items, providing a competitive edge in the custom apparel industry.

What are recent developments in DTF printing technology?

Recent developments in DTF printing technology include advancements in printers and inks that improve adhesion and durability of prints. Additionally, the technology supports sustainability initiatives by enabling lower waste production processes, aligning with the growing consumer demand for eco-friendly printing solutions.

| Aspect | Details |

|---|---|

| Introduction | DTF (Direct-to-Film) transfers are integral in custom apparel, providing various benefits and opportunities. |

| What are DTF Transfers? | A printing method where designs are printed on a special film, which is then heat-applied to fabrics, offering vibrant, detailed designs. |

| Benefits of DTF Transfers | 1. High quality and vibrant colors. 2. Versatile applications across multiple materials. 3. Cost-effective for short orders. 4. Ease of use with minimal equipment. 5. Fast turnaround times for customer demands. |

| Recent Trends | Advancements in printer technology and inks improve adhesion/durability, while sustainable practices enhance efficiency in production. |

| Conclusion | DTF transfers are reshaping the custom apparel industry by providing quality, versatility, and efficiency, making them essential for growth. |

Summary

DTF transfers are revolutionizing the custom apparel industry due to their unique blend of quality, versatility, and affordability. This advanced printing method utilizes a special film to apply vibrant designs swiftly, making it ideal for businesses needing quick turnaround times without compromising on quality. The ability to print on various fabrics, including polyester and nylon, coupled with cost-efficiency for short runs, positions DTF transfers as a smart choice for both new and established custom apparel companies. As the technology continues to evolve, those who adapt and incorporate DTF transfers into their offerings will not only meet but exceed customer expectations, ensuring a competitive edge in the rapidly changing marketplace.