DTF Transfers, known as Direct to Film transfers, are transforming the landscape of custom printing within the apparel industry. This innovative technique has emerged as a game-changer, offering businesses a reliable method to produce vibrant, high-quality designs on various fabrics. By understanding how DTF transfers work, manufacturers can maximize their printing capabilities while implementing cost-effective solutions. With direct application on textiles and a reduced need for pre-treatment, the benefits of DTF transfers are becoming increasingly apparent. From custom t-shirts to promotional merchandise, the versatility of DTF printing applications is making it a top choice for those seeking exceptional results.

Direct to Film printing, or DTF printing, has quickly become a buzzword in the printing industry, synonymous with innovation and quality. This method not only allows for intricate designs but also boasts remarkable durability, making it ideal for a diverse range of applications. By leveraging this technology, businesses can create unique designs that stand out, whether it’s for custom apparel or promotional items. The efficiency of DTF printing processes significantly enhances productivity, allowing for cost-effective production without compromising on quality. As industries embrace the advantages offered by direct film printing, staying informed on its applications can empower professionals to tap into its full potential.

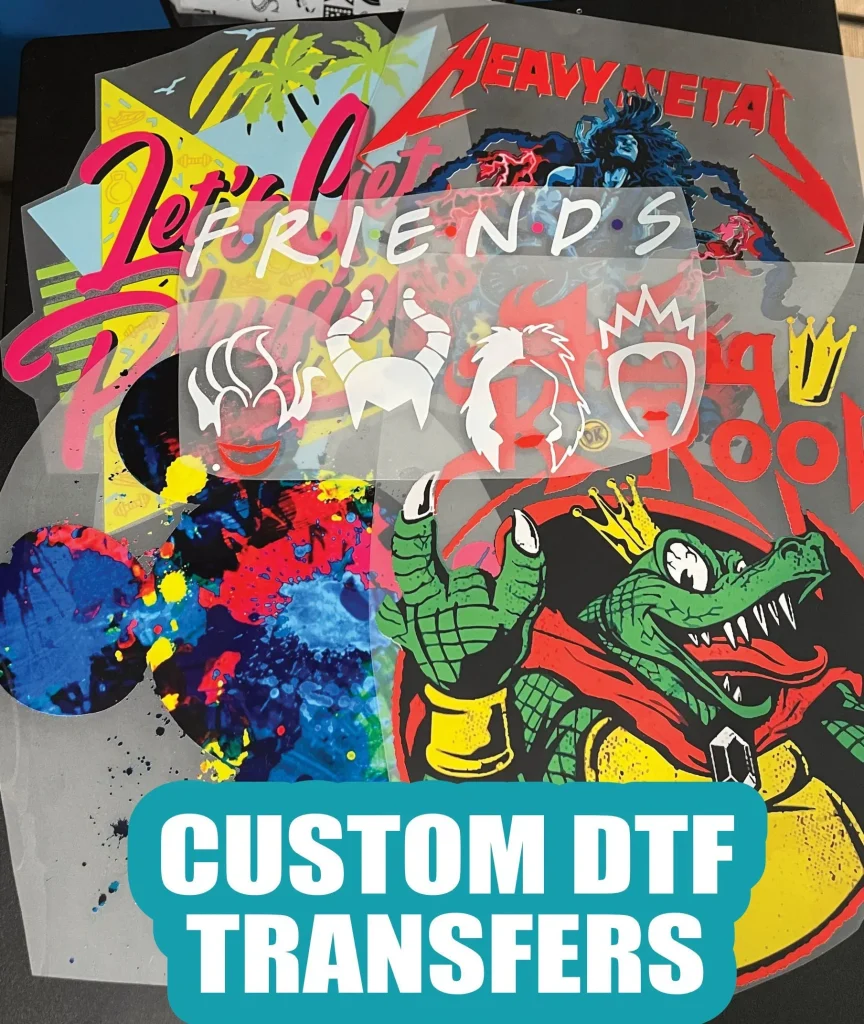

Understanding DTF Transfers: The Future of Custom Printing

DTF transfers, or Direct to Film transfers, have emerged as a significant innovation within the printing industry, specifically for custom apparel. By utilizing eco-solvent inks and a specialized film, DTF printing offers the ability to create extravagant designs and vibrant colors that stand out on a variety of substrates. The process encompasses printing an image onto film and then transferring it to fabric through heat and pressure, which efficiently binds the ink to the material. This results in high-quality prints that are both durable and striking, making DTF printing a preferred option for merchandise and apparel.

As the printing landscape evolves, DTF transfers provide versatility that previous methods lack. Unlike screen printing, which requires extensive setup and is generally profitable only in large quantities, DTF brings efficiency to lower-volume orders. With no need for pre-treatment of fabrics, this technology enables seamless transitions between different textile types, from cotton to polyester blends. This ability to accommodate various materials broadens the creative canvas for designers, enhancing the potential for unique and custom creations.

Revolutionizing Custom Apparel with DTF Printing Applications

The application scope of DTF printing is vast, cutting across various industries while concentrating heavily on the custom apparel segment. From sporting jerseys and team merchandise to stylish custom t-shirts for events, DTF offers unparalleled flexibility in achieving highly personalized designs. Businesses are increasingly adopting DTF technology due to its capability to reproduce intricate patterns and vivid colors that capture client attention and foster brand identity.

Moreover, the rise in demand for promotional merchandise underscores the importance of DTF printing applications. Companies leverage this technique to craft eye-catching merchandise that leaves a lasting impression. For instance, vibrant logos on promotional items not only amplify brand visibility but also enhance customer loyalty through quality and design. The adaptability of DTF allows for rapid production, catering to the dynamic needs of fashion designers who require swift turnaround times for new collections—ensuring that creativity meets market demand.

The Benefits of DTF Transfers in Modern Printing

One of the key benefits of DTF transfers is their ability to produce visually stunning prints without the need for pre-treatment. This streamlining of the printing process reduces operational time and costs, making it an excellent choice for small businesses looking to optimize their production workflows. Furthermore, since DTF technology allows direct application onto a variety of fabrics—including both light and dark textiles—designers can exploit greater creativity without worrying about compatibility limitations that constraint traditional printing methods.

Another significant advantage of DTF transfers is their environmental impact. By minimizing waste through the use of gang sheets, which allow multiple designs to be printed on a single film sheet, DTF reduces material consumption significantly. This eco-friendly approach meets the increasing consumer demand for sustainable practices in the fashion and printing industries. Not only do DTF prints maintain their vibrancy after multiple washes, but they also offer durability that caters to high standards of customer satisfaction, solidifying their status as a reliable printing choice.

The Science Behind How DTF Transfers Work

Understanding how DTF transfers function is crucial for anyone looking to adopt this innovative printing method. The process initiates with the selection of an image, which is then printed onto a specialized film using eco-solvent inks. This film effectively captures the intricacies of the design, allowing each detail to be transferred accurately onto the intended fabric using heat and pressure. The application of heat is critical, as it encourages the inks to adhere to the textile’s fibers, resulting in a lasting and vibrant print.

Additionally, the technique provides significant advantages over older methods, such as its ability to work with various types of clothing, from athletic wear to casual apparel. This adaptability not only diminishes the restrictions previously imposed by specific printing processes but also allows for more diverse and creative designs. As the technology continues to evolve, the mechanics behind DTF transfers will only enhance, pushing boundaries in print quality and production efficiency, making it essential knowledge for today’s printing professionals.

Cost-Efficiency and Time-Saving with Gang Sheets in DTF

Utilizing gang sheets in DTF printing not only enhances efficiency but also drives down operational costs for businesses. By allowing multiple designs to be printed on one sheet of film, this innovative approach minimizes material usage and waste, significantly reducing printing costs. For small businesses and independent designers, being able to print several designs at once without scaling up to larger print runs means they can meet client demands more swiftly and economically.

In addition to cost savings, gang sheets drastically cut down on production times. This is especially advantageous for custom apparel businesses that experience fluctuating order volumes. By leveraging gang sheets, brands can execute a more agile production process, fulfilling multiple orders simultaneously and ensuring faster delivery times. This aligns perfectly with the demands of a fast-paced market, where customer expectations for quality and speed are higher than ever.

Enhancing Quality and Durability in Printed Designs

DTF transfers are renowned for their exceptional quality and durability compared to traditional printing methods. The ability to produce prints that maintain their vibrancy even after repeated washes makes DTF an attractive choice for clothing brands seeking to provide customers with long-lasting products. Unlike other printing techniques that may cause colors to fade or designs to peel, DTF inks bond strongly with fabric fibers, ensuring that even intricate details remain sharp and clear regardless of wear.

Furthermore, the durability of DTF transfers is particularly critical as brands aim to uphold their reputations in competitive markets. High-quality prints that resist fading communicate professionalism and build consumer trust. As fashion trends shift towards sustainable consumption, the long-lasting nature of DTF-printed fabrics aligns with current consumer preferences for quality over quantity, establishing DTF printing as a progressive solution for modern apparel production.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs on a special film using eco-solvent inks. The printed film is then applied to fabrics using heat and pressure, allowing for vibrant, durable designs on various materials.

What are the benefits of DTF transfers over traditional printing methods?

The benefits of DTF transfers include no pre-treatment requirement, the ability to print on a wide range of fabrics, reduced material waste through gang sheets, and vibrant color reproduction. This makes DTF a versatile and cost-effective choice.

What applications are best suited for DTF printing?

DTF printing is ideal for a variety of applications, including custom t-shirts, promotional merchandise, fashion designs, and home decor items. Its versatility allows for high-quality prints on anything from sports jerseys to pillows.

How does the use of gang sheets optimize DTF printing?

Gang sheets optimize DTF printing by allowing multiple designs to be printed on one large sheet. This method reduces material costs and production time, making it efficient for businesses needing to produce various designs simultaneously.

How durable are DTF transfers compared to other printing methods?

DTF transfers are highly durable, capable of withstanding multiple washes without fading. This durability, coupled with vibrant colors, makes DTF an attractive option for businesses prioritizing quality in their clothing products.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and blends. This versatility allows designers and businesses to create custom apparel on various material types.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A method that uses eco-solvent inks to print designs onto a special film, which is then transferred to fabrics using heat and pressure, allowing for vibrant and durable prints. |

| Gang Sheets Importance | Gang sheets are large sheets where multiple designs are printed at once, optimizing efficiency and reducing costs for small businesses. |

| Applications | Used in custom apparel, promotional merchandise, fashion designs, and home decor, allowing for high-quality and creative outputs. |

| Advantages of DTF Transfers | No pre-treatment required, works on a wide range of fabrics, reduced waste, and vibrant color reproduction. |

Summary

DTF Transfers are revolutionizing the printing industry, particularly for custom apparel. By providing a versatile, durable, and efficient method of applying designs directly onto fabrics, DTF transfers cater to various applications from personalized gifts to sports jerseys. Their ability to produce vibrant colors and intricate details while minimizing material waste marks a significant advancement in printing technology. As businesses and designers embrace DTF transfers, they unlock new creative possibilities and enhance the quality of their offerings. Understanding DTF transfers is essential for anyone looking to thrive in this dynamic and evolving market.