In the realm of modern textile printing, the DTF gangsheet builder stands out as a transformative tool for graphic designers and businesses alike. By leveraging the benefits of Direct-to-Film printing, users can optimize their artwork while minimizing costs associated with material waste. This innovative technology not only enhances the printing workflow but also guarantees high-quality results on various fabrics. In this guide, we will dive into essential DTF printing tips that can elevate your designs and showcase the significance of design optimization. From selecting the right DTF printing materials to exploring sustainable DTF practices, our insights will help you master the art of utilizing a DTF gangsheet builder effectively.

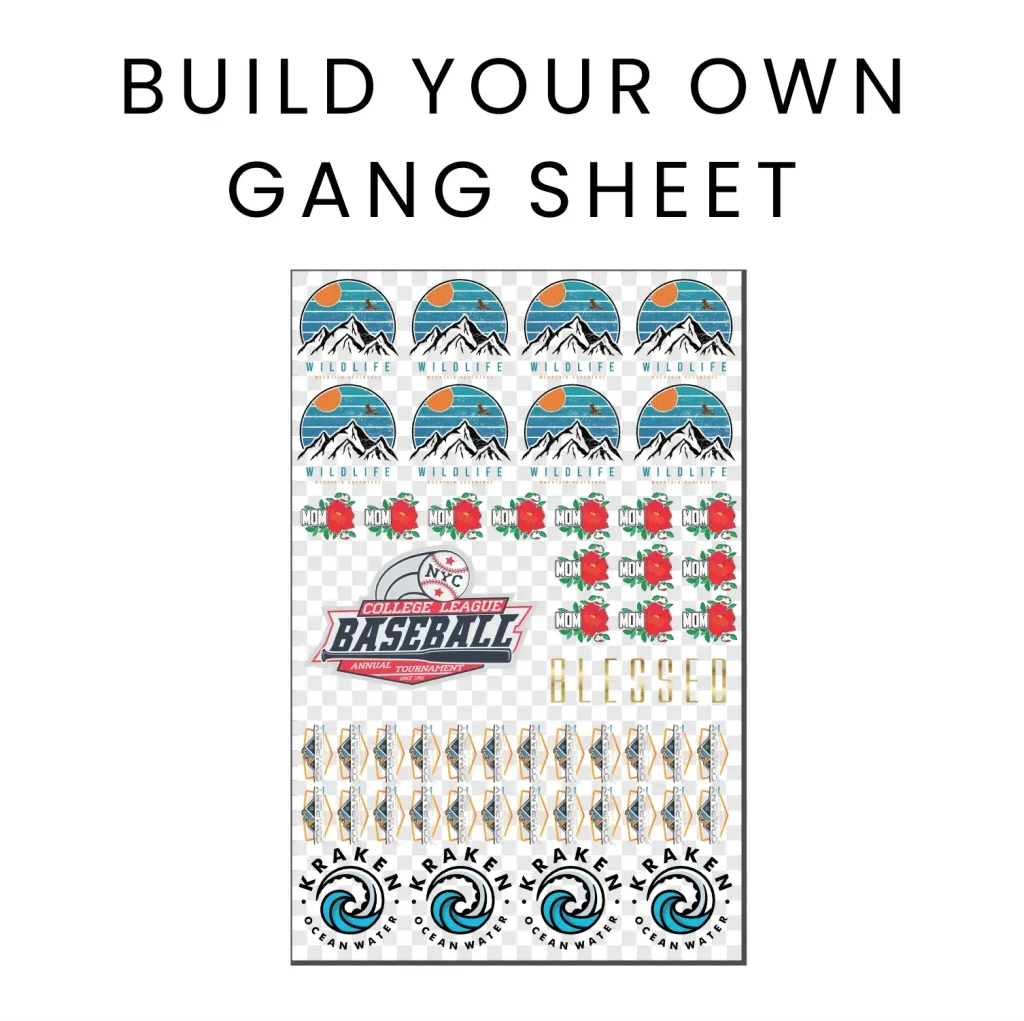

The DTF gangsheet builder, an essential component of Direct-to-Film printing, revolutionizes how designs are created and applied on textiles. This advanced tool allows users to consolidate multiple graphics on a single transfer sheet, enhancing efficiency and cost-effectiveness. By understanding the intricacies of the DTF printing process, designers can refine their artwork, ensuring every detail shines through on the chosen substrate. Furthermore, exploring methods for optimizing design layouts and selecting quality materials will be crucial in yielding superior outcomes. As the industry increasingly emphasizes sustainability, incorporating eco-friendly DTF practices can also enhance your brand’s appeal and market relevance.

Understanding Direct-to-Film (DTF) Printing Benefits

Direct-to-Film (DTF) printing has emerged as a groundbreaking technique in the textile industry, providing a range of advantages over traditional printing methods. One of the primary benefits is its ability to produce high-quality prints that are remarkably vibrant and durable. This makes DTF a preferred choice for businesses eager to create custom apparel that stands out. Unlike traditional printing methods that often struggle with color fidelity, DTF ensures that intricate designs and vibrant colors remain intact on various fabrics, making it ideal for everything from t-shirts to intricate accessories.

Moreover, DTF printing’s versatility allows for a broader selection of materials to be used. It can effectively print on cotton, polyester, and blends, expanding the possibilities for product offerings. Additionally, the reduced setup time and lower cost per transfer make DTF printing a cost-effective solution for both small and large scale productions. These factors combined make DTF technology not only innovative but essential for brands looking to enhance their product line.

Maximizing Efficiency with a DTF Gangsheet Builder

A DTF gangsheet builder is pivotal in maximizing efficiency during the printing process. By grouping multiple designs onto a single gangsheet, you can minimize material usage and reduce waste significantly. This strategic organization ensures that your production process is streamlined and economical, as it allows you to print multiple designs in a single pass. Thus, utilizing a DTF gangsheet builder not only optimizes your workspace but also contributes to a more sustainable printing practice.

Furthermore, gangsheet creation allows designers to experiment with layouts without the anxiety of wasting resources. With the ability to adjust and rearrange designs easily, users can find the optimal configuration that maximizes space. This encourages creativity and innovation, as designers can test out bold ideas without the fear of financial repercussions. In a market that thrives on uniqueness and originality, leveraging a DTF gangsheet builder positions businesses ahead of competitors.

Essential Tips for Design Optimization in DTF Printing

Design optimization is a critical aspect of succeeding in DTF printing, specifically when utilizing a gangsheet builder. Start by focusing on layout and image clarity; ensuring that each design is crisp and visually appealing is paramount. Using graphic design software such as Adobe Illustrator can help streamline this process, offering tools that assist in resizing and scaling images perfectly for gangsheet use. Reducing unnecessary spacing between designs can allow for more prints on a single sheet, thereby reducing material costs.

Additionally, embracing efficient design elements such as fewer borders and simplified color palettes can enhance overall print quality while still capturing the essence of the original artwork. Consider the materials that will be used in the transfer; understanding how different fabrics respond to color can play a significant role in final output. Making informed design choices that take into account both aesthetic appeal and technical feasibility will ultimately lead to more successful DTF prints.

The Importance of Quality DTF Printing Materials

Choosing high-quality materials for DTF printing plays a crucial role in determining the durability and appearance of the final product. The type of transfer film and inks used can significantly affect the overall print quality on the fabric. It is essential to invest in reliable DTF inks that are specifically designed for this printing technique, as they offer superior adhesion and vibrancy. Doing thorough research on different brands helps to ensure you select products that deliver consistent results.

In addition to inks, selecting the proper transfer film is equally important. Compatibility with your printer and the specific fabric type you are working with can prevent print failures and ensure long-lasting designs. Prioritizing premium materials may incur higher initial costs but can lead to enhanced durability, reduced reprints, and ultimately higher customer satisfaction — key factors in establishing a successful DTF printing operation.

Calibration Techniques for Quality DTF Prints

Calibration of print settings is a fundamental practice that can dramatically impact the quality of DTF prints. Ensuring that your printer is regularly calibrated for both alignment and color accuracy is essential to achieving optimal results. This involves aligning the print heads and adjusting color settings based on the specific inks and materials used, which can help prevent common issues such as misalignment and color discrepancies.

Additionally, conducting test runs before committing to large production runs can save time, resources, and frustration. Test prints allow you to evaluate ink distribution, verify color accuracy, and make any necessary adjustments before full-scale printing. Staying proactive with calibration helps maintain consistency and quality across all applications, reinforcing your brand’s reputation for reliability and excellence.

Incorporating Sustainability in DTF Practices

As consumer awareness regarding environmental issues grows, integrating sustainability into DTF printing practices is becoming increasingly essential. Utilizing eco-friendly inks and sustainable materials for DTF printing not only reduces your environmental impact but also enhances your brand’s image. Committing to sustainable practices can set your business apart in a competitive market that emphasizes social responsibility.

Moreover, transparent communication about your sustainability efforts can resonate with customers and strengthen their loyalty towards your brand. Sharing your journey towards greener practices, whether through the use of biodegradable materials or energy-efficient printing processes, can inspire trust and foster relationships with environmentally-conscious consumers. Ultimately, adopting sustainable DTF practices isn’t just about compliance—it’s about leading a movement that champions responsible manufacturing.

Frequently Asked Questions

What is the purpose of a DTF gangsheet builder in Direct-to-Film printing?

A DTF gangsheet builder is designed to optimize the arrangement of multiple designs on a single transfer film sheet. This maximizes material usage and minimizes waste in Direct-to-Film printing, ensuring cost efficiency and streamlined production.

What are some essential DTF printing tips for using a gangsheet builder?

When using a DTF gangsheet builder, focus on design optimization by layering images effectively, selecting high-quality DTF printing materials, and regularly calibrating your printer. Additionally, utilizing specialized software can enhance layout management for better results.

How can design optimization improve results with a DTF gangsheet builder?

Design optimization is crucial for maximizing the use of space on a DTF gangsheet. By resizing images, minimizing borders, and arranging designs thoughtfully, you can fit more artwork on a single film sheet, thus reducing material costs and enhancing the print output.

What types of DTF printing materials should I consider using?

It’s important to select high-quality DTF printing materials, including premium inks and transfer films that are compatible with your printer. This ensures better adhesion and durability of the prints, leading to a superior final product.

How can I incorporate sustainable DTF practices when using a gangsheet builder?

To incorporate sustainable DTF practices, consider using eco-friendly inks and efficient printing techniques to reduce material waste. Sharing these practices with your customers can also enhance your brand image and appeal to environmentally conscious consumers.

What software tools are beneficial for maximizing the potential of a DTF gangsheet builder?

Specialized software that includes advanced layout management tools, design alignment features, and effective file management capabilities can greatly enhance your experience with a DTF gangsheet builder, improving efficiency and print quality.

| Key Point | Details |

|---|---|

| Understanding DTF Printing | DTF printing allows high-quality images to be printed directly onto a transfer film, making it ideal for various fabrics. |

| What is a DTF Gangsheet? | A gangsheet compiles multiple designs on one transfer film, optimizing costs and streamlining production. |

| Design Optimization | Utilize software to layer and resize images, minimizing borders to maximize design count on the sheet. |

| Selecting High-Quality Materials | Choose high-quality inks and transfer films to enhance durability and performance. |

| Calibration of Print Settings | Regular calibration ensures color accuracy and alignment, preventing misprints and errors. |

| Utilizing Software Tools Effectively | Leverage specialized software for layout management and file handling to improve efficiency. |

| Keeping Up with Market Trends | Stay updated on trends to remain competitive and meet consumer preferences effectively. |

| Emphasizing Sustainability | Consider eco-friendly practices in printing to improve brand image and reduce environmental impact. |

Summary

DTF gangsheet builder serves as an essential tool for every business aiming to enhance their printing capabilities. As you optimize your designs and select quality materials, remember that successful utilization of the gangsheet builder hinges on effective software tools and ongoing market awareness. By incorporating sustainable practices, your business not only improves its operational efficiency but also aligns with the increasing value consumers place on environmentally responsible brands. In conclusion, mastering the use of a DTF gangsheet builder not only transforms your textile designs but also positions your brand for long-term growth and success in a competitive market.