The DTF Gangsheet Builder is revolutionizing the way businesses approach custom printing solutions, particularly in the realm of DTF printing. This innovative tool allows users to efficiently create gang sheets that accommodate multiple designs, maximizing material usage while minimizing waste. As the demand for high-quality prints surges, the DTF Gangsheet Builder stands out for its ability to deliver vibrant and durable results, making it an invaluable asset for both small businesses and established print shops. With a focus on cost-effectiveness and speed, this technology significantly enhances the production process, yielding prints that rival traditional screen printing and direct-to-garment methods. As we delve deeper into the intricacies of the DTF Gangsheet Builder, we will explore its features, advantages, and how it compares to other printing techniques in several key areas.

In the landscape of personalized printing, the advent of Direct-to-Film technology has ushered in a new era of efficiency and cost management. The gang sheet printing method, exemplified by the DTF Gangsheet Builder, allows for the juxtaposition of numerous custom designs within a single print run, leading to substantial savings in materials and production time. This technique is particularly useful for businesses seeking to provide high-quality prints on textiles while maintaining a competitive edge against conventional methods such as screen and direct-to-garment printing. By harnessing the power of this advanced tool, print service providers can achieve exceptional color vibrancy and durability, ensuring that their products not only meet but exceed customer expectations. This article will further investigate the functionalities of the DTF Gangsheet Builder and its impact on the custom printing industry.

Understanding DTF Printing: A Game Changer

Direct-to-Film (DTF) printing has emerged as a transformative solution in the textile printing industry. This innovative technology enables vibrant and intricate designs to be printed directly onto a unique film, which is later transferred onto fabrics. Its efficiency in producing high-quality prints with dazzling color fidelity makes it a favorite among custom apparel manufacturers. By marrying the precision of digital printing with a versatile transfer method, DTF stands out as an exceptional alternative to traditional printing techniques.

Moreover, DTF printing offers several advantages that attribute to its rising popularity. With the capability to handle a variety of materials such as cotton, polyester, and blends, it opens doors for businesses targeting diverse market segments. The ability to print complex designs in smaller runs translates to significant savings for businesses, especially those starting out and looking to manage costs effectively. With its impressive print quality and reduced waste, DTF printing is not just a trend but a significant step forward in custom printing solutions.

The DTF Gangsheet Builder: Maximizing Efficiency

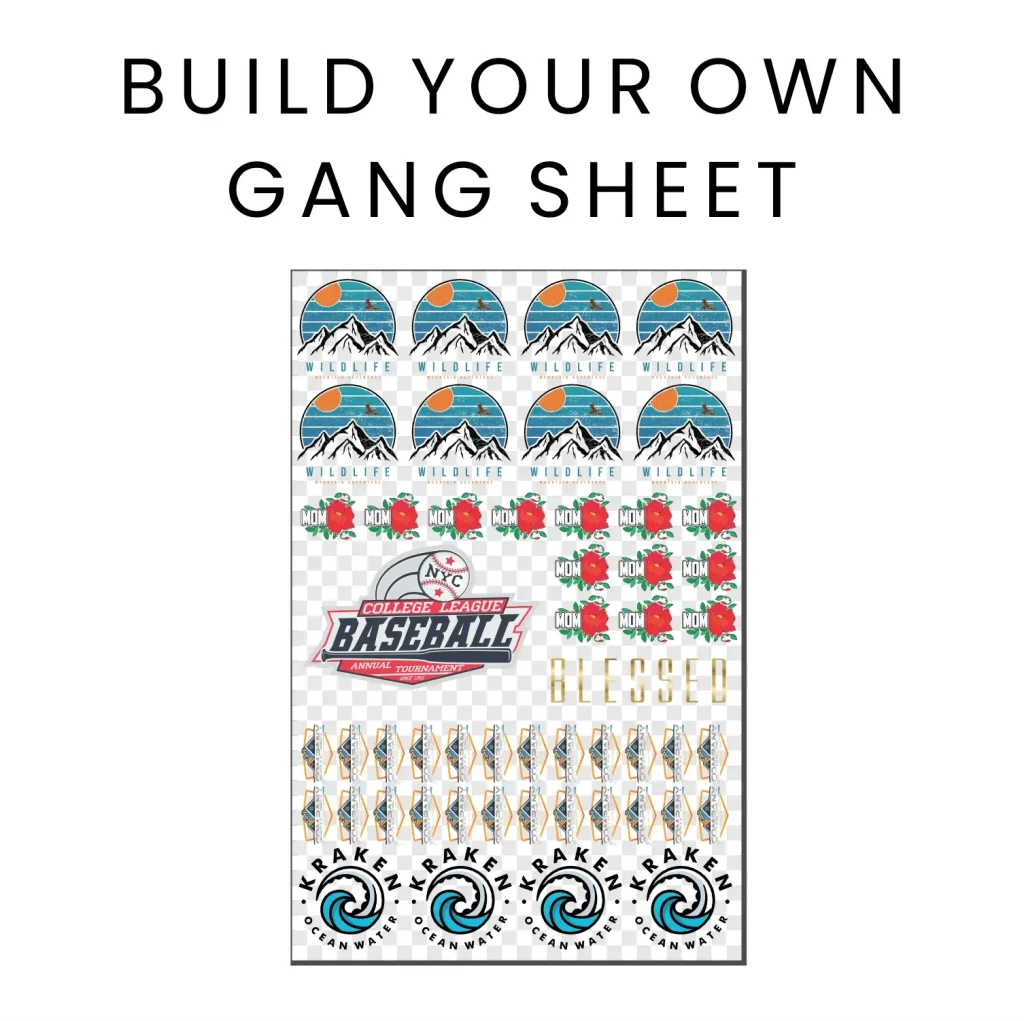

The DTF Gangsheet Builder is a revolutionary tool designed to enhance the efficiency of the DTF printing process significantly. By allowing users to print multiple designs simultaneously on a single gang sheet, this tool maximizes material usage while minimizing film and ink consumption. This feature is particularly beneficial for small businesses that need to keep costs low while maximizing profitability. Businesses can produce a variety of designs in one go, leading to substantial time savings in production.

In addition to being cost-effective, the DTF Gangsheet Builder helps streamline workflows within printing operations. As the printing landscape becomes more competitive, efficiency is paramount. With the capability to easily manage and print multiple designs, businesses can meet changing customer demands quickly without compromising on quality. This flexibility not only enhances turnaround times but also positions businesses to take on more diverse projects, widening their service offerings.

Pros and Cons of the DTF Gangsheet Builder

Like any technology, the DTF Gangsheet Builder has its advantages and drawbacks. Among the most notable pros is its cost-effectiveness. By utilizing multiple designs on a single sheet, companies can significantly reduce their expenses on films and inks, directly impacting their bottom line. Additionally, the speed at which DTF prints can be produced makes it an ideal solution for businesses that deal with fluctuating demand, allowing them to efficiently address urgency without sacrificing quality.

However, there are some considerations to keep in mind. The initial investment for DTF printing equipment might be substantial for startups, which can pose a barrier for entry. Furthermore, a learning curve exists for mastering the techniques involved in DTF printing, which can temporarily slow production. Regular maintenance is also essential to keep printers functioning optimally, further adding to operational complexities. It is crucial for businesses to weigh these factors against the potential long-term benefits.

DTF vs. Direct-to-Garment (DTG) Printing

When comparing DTF printing to Direct-to-Garment (DTG) printing, several key differences arise, particularly in application suitability and cost. DTG printing excels in delivering seamless designs with a soft finish, making it ideal for high-quality apparel. However, the high costs associated with DTG for large orders limit its overall practicality for budget-conscious businesses. In contrast, DTF printing excels at handling bulk jobs with lower setup costs, making it a more economical choice for companies focusing on larger runs.

Additionally, DTF printing provides versatility in terms of compatibility with various fabric types, which DTG may not match. The ability of DTF to adapt to different substrates can provide businesses with a broader market reach and the flexibility to cater to diverse client needs. Understanding these distinctions allows businesses to make informed decisions about which printing method aligns with their objectives—be it for small custom runs or larger production needs.

DTF vs. Screen Printing: Which is Better?

Screen printing has long been a staple in the printing industry, known for its durability and vibrant color outputs. However, when contrasted with DTF printing, especially for smaller runs, DTF proves to be a more practical solution due to its minimal setup requirements. While traditional screen printing can yield lower costs per unit in larger orders, DTF’s flexibility with design and ability to manage smaller batches with high-quality results often make it a more appealing option for companies looking to diversify their offerings.

Moreover, the color richness and print durability offered by DTF technology can rival, and in some cases exceed, those of screen printing methods. As businesses increasingly look to differentiate their products in a saturated market, adopting the DTF approach may provide the best of both worlds: high-quality, customizable prints with lower waste and enhanced production efficiency. This evolving landscape creates exciting opportunities for innovators in the printing sphere.

Recent Trends and Innovations in DTF Technology

The advancement of DTF technology continues to reshape the printing landscape, with recent innovations focusing on enhancing both the quality and efficiency of the printing process. Improvements in ink formulations are allowing for better adhesion and more vibrant colors, which substantially increases the competitive edge of DTF printing. As manufacturers refine their approaches to DTF technology, businesses are becoming more equipped to handle diverse demands with increased output, further solidifying the method’s place in the industry.

In addition to ink improvements, recent developments in printer technology have made DTF printing more accessible to a broader range of users. Increased user-friendliness in printer operations reduces the barriers for entry for small businesses and startups. These innovations not only enhance print quality but also help streamline the overall workflow, making the DTF process smoother and more effective. Companies looking to adopt or upgrade their printing capabilities stand to benefit immensely from these trends, ensuring they remain competitive in an ever-evolving marketplace.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool for Direct-to-Film (DTF) printing that enables the combination of multiple designs on a single gang sheet. This process optimizes material use, reduces waste, and cuts costs, making it an efficient solution for custom printing projects.

How does DTF printing compare to screen printing for custom printing solutions?

DTF printing offers greater flexibility and cost-effectiveness for smaller runs when compared to traditional screen printing. It requires less setup time and allows for quicker turnaround times, making it a preferred choice for businesses that need to adapt designs frequently.

What are the advantages of using the DTF Gangsheet Builder for print quality?

The DTF Gangsheet Builder enhances print quality by utilizing advanced inks that produce vibrant colors and durable prints. This method is particularly appreciated for its high resolution and impressive longevity, often surpassing other techniques like heat transfer vinyl.

Can the DTF Gangsheet Builder handle a variety of materials?

Yes, the DTF Gangsheet Builder is versatile and capable of printing on a wide range of fabrics including cotton, polyester, and blends. This adaptability expands its application across different sectors, such as fashion and merchandise.

What are some challenges associated with the DTF Gangsheet Builder?

While the DTF Gangsheet Builder is highly efficient, it does involve initial investment costs for equipment and supplies. Additionally, there is a learning curve regarding application techniques, and regular maintenance is required to sustain print quality.

Are there any recent advancements in DTF printing technology?

Yes, recent developments in DTF printing technology focus on improving ink chemistry and printer capabilities. These innovations enhance print quality and efficiency, making DTF solutions increasingly accessible for various businesses.

| Key Points | Details |

|---|---|

| Introduction | DTF printing is revolutionizing the printing landscape, and the DTF Gangsheet Builder is a tool for efficiency and cost-effectiveness. |

| What Is DTF Printing? | A method that prints designs onto a special film for transfer onto fabrics. Ideal for vibrant custom apparel designs. |

| Pros of DTF Gangsheet Builder | 1. Cost-effective – lowers per-unit costs, 2. Fast turnaround times, 3. Versatility across different materials, 4. High-quality, durable prints. |

| Cons of DTF Gangsheet Builder | 1. High initial investment, 2. Requires skill to master, 3. Needs regular maintenance. |

| Comparison with Other Methods | DTF is more cost-effective than DTG for bulk orders and easier for smaller runs compared to screen printing. |

| Recent Developments | Innovations in DTF technology are improving print quality and user-friendliness. |

| Conclusion | Despite initial costs, the DTF Gangsheet Builder offers substantial benefits that position it favorably against traditional printing methods. |

Summary

The DTF Gangsheet Builder is an innovative tool that empowers businesses to optimize their printing processes effectively. By allowing the combination of multiple designs on a single sheet, it not only reduces costs significantly but also enhances speed and versatility across materials. This makes it an exceptional solution for companies aiming to thrive in the competitive printing market. Although there are initial investments and a learning curve involved, the overall advantages—such as improved print quality and operational efficiency—make the DTF Gangsheet Builder a crucial asset for any print service provider. As the technology continues to evolve, it is essential for businesses to stay updated on these developments to maximize their productivity and competitiveness.