DTF gangsheet builder is transforming how shops plan designs for direct-to-film printing, delivering a smarter route to higher throughput and more predictable results for bulk orders. In the context of the DTF printing workflow, this tool helps reduce waste and streamline setup by automating layout decisions, margins, bleed considerations, and even color separation sequencing when integrated with compatible RIP software. Compared with traditional sheet setups, the built-in layout optimizes space and minimizes misalignment, while also enabling better repeatability across multiple runs and providing a clear path to scaling production without sacrificing accuracy. Users often see improvements in gangsheet printing efficiency and a lower cost per garment as designs share ink, margins, and color alignment on one sheet, reducing handling steps for operators and lowering operational variability. For apparel printers and production managers, considering the DTF gangsheet advantages can guide adoption, helping boost throughput while maintaining color consistency across DTF sheets, with a measurable impact on lead times, waste, and overall profitability.

An alternative way to frame the concept is a multi-design layout planner that places several artwork files onto a single DTF sheet. This grouped-design approach supports a streamlined printing workflow by reducing changeovers and improving color consistency across designs. Other terms you may encounter include large-format sheet layouts, batch-print planning tools, and design consolidation software that maximize each run. From an SEO perspective, these terms signal the same underlying idea: packing multiple designs onto a single sheet to save time, ink, and film while maintaining quality.

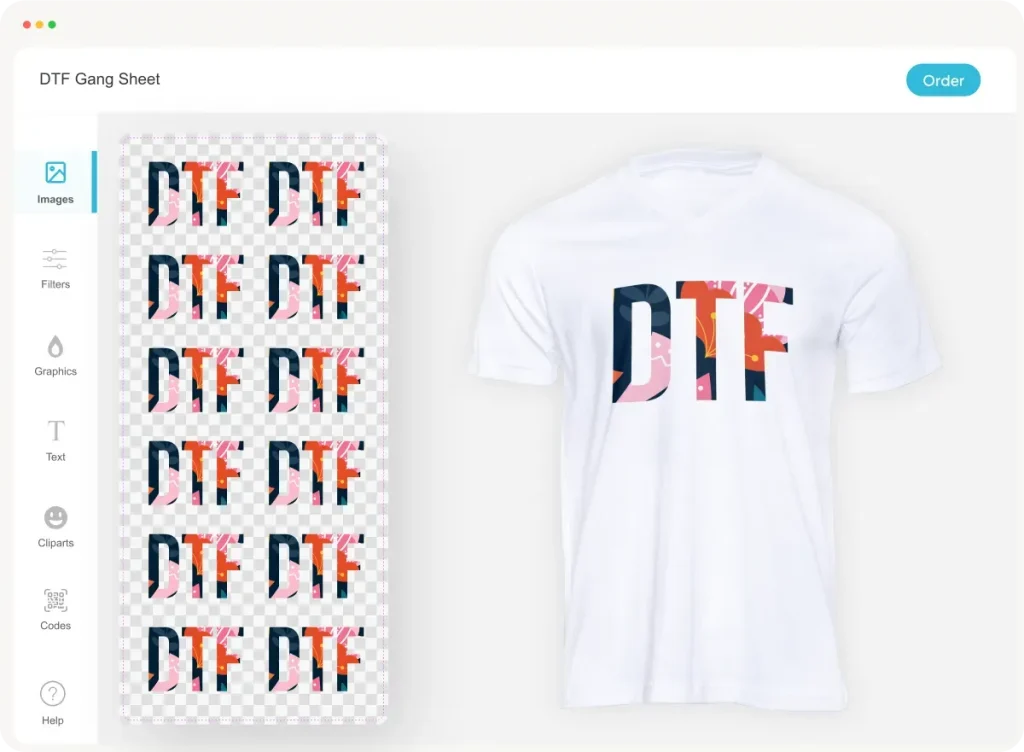

Understanding the DTF gangsheet builder and its impact on DTF sheets

A DTF gangsheet builder is a software-driven workflow tool that arranges multiple designs on a single large sheet for direct-to-film printing. By defining margins, bleed, and layout constraints, it creates a single gang sheet that maximizes the number of designs per print. When integrated with a RIP and compatible hardware, this tool can automate color separation, spacing, and alignment, driving more efficient use of ink, transfer film, and press time.

The result is a streamlined DTF printing workflow where operators spend less time on repetitive setup changes and more on producing multi-design orders. For shops handling several designs per run, the gangsheet approach can improve consistency across designs that share the same color profile, while reducing misprints caused by manual layout errors. In short, the DTF gangsheet builder is a central piece of improving gangsheet printing efficiency and overall production predictability.

DTF gangsheet advantages: boosting efficiency, consistency, and scale

One of the primary DTF gangsheet advantages is faster job setup and higher throughput. By packing multiple designs onto one sheet, you reduce the number of print runs, limit color changes, and cut loading/unloading time. This directly translates into improved gangsheet printing efficiency and lower labor costs per order.

Beyond speed, the approach helps with ink and film utilization, reducing waste and providing more consistent color output across designs that share color profiles. When managed correctly, the DTF gangsheet advantages extend to better predictability for production planning and easier scale-up for mid-sized to larger operations, aligning production with demand without sacrificing quality.

DTF printing workflow optimization with gangsheet layouts

Gangsheet layouts influence the DTF printing workflow by automating many prepress tasks—layout optimization, automatic spacing, and alignment—so operators can focus on monitoring print quality rather than manual positioning. When combined with appropriate RIP settings, these layouts harmonize color separation and transfer timing across multiple designs on a single sheet.

Key performance indicators like output per hour, material waste, and setup time are positively impacted when the gangsheet workflow is carefully calibrated. The right DTF gangsheet workflow can reduce color drift and misprints, provided margins and color management are tuned to the printer’s capabilities and the DTF sheets you use.

Traditional sheet setups vs DTF gangsheet: practical differences and decisions

Traditional sheet setups typically print one design per sheet or only a few designs per sheet with manual alignment, offering simplicity but often creating bottlenecks as volume grows. This approach can work well for very small runs or single-design orders, yet it tends to lag in throughput and waste management when demand increases.

The decision to move toward DTF gangsheet layouts hinges on scale, design variety, and tolerance for automation. Mid-sized to larger operations usually gain the most from consolidating multiple designs into a single print run, but small shops may still benefit from reduced waste and setup time. Evaluating your volume, color requirements, and equipment compatibility will guide whether traditional sheet setups or gangsheet layouts best fit your operation.

ROI and cost considerations in gangsheet-based production

ROI analysis for gangsheet-based production should weigh upfront investment in a DTF gangsheet builder against ongoing savings in ink, film, and labor. Wiser layout density and improved process control can lower the cost per garment by reducing waste and the number of reprints caused by misalignment or color drift.

Be mindful of design complexity and color-management challenges; pilot runs are essential to validate margins, color accuracy, and transfer quality. When properly integrated with your RIP and printer ecosystem, the gangsheet approach can deliver meaningful returns through increased throughput and more predictable production cycles.

Best practices for using a DTF gangsheet builder with DTF sheets

Start by building flexible templates that cover common product lines and design families. Establish consistent margins, bleed, and gutter handling to maximize DTF sheets while avoiding overlaps. Align color profiles across gang sheets and ensure the builder outputs are compatible with your DTF sheets and transfer film.

Focus on validation and documentation: run pilot proofs, calibrate color with ICC profiles, and maintain a clear record of settings for repeatability. Regular calibration of the printer, inks, and film, together with robust proofing and post-print workflows, will help you realize the full potential of the DTF gangsheet builder and maintain high quality across shifts.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it improve gangsheet printing efficiency?

A DTF gangsheet builder is software that arranges multiple designs on a single large gang sheet for DTF printing. It improves gangsheet printing efficiency by maximizing designs per sheet, reducing setup time, and cutting waste in ink and film, especially when designs share a color profile and can be processed through a compatible RIP.

How does a DTF gangsheet builder compare to traditional sheet setups in terms of throughput and material waste?

Compared with traditional sheet setups, a DTF gangsheet builder packs multiple designs onto one sheet, boosting throughput and lowering setup changes. It minimizes material waste by optimizing spacing and margins, whereas traditional single-design sheets can lead to more scrap and higher per-garment costs.

What are the key advantages of using a DTF gangsheet builder in the DTF printing workflow?

Key advantages include gangsheet printing efficiency, faster job setup, and improved color consistency across designs sharing the same color profile. The builder can automate color separation, spacing, and alignment, integrating with RIP software to streamline the DTF printing workflow.

How does color management work when using a DTF gangsheet builder across DTF sheets?

Color management with a DTF gangsheet builder relies on standardized color profiles and RIP integration to maintain consistency across all designs on a gang sheet. Using ICC profiles and calibrated workflows helps minimize color drift between designs and across sheets, with proofing to verify results.

What features should I look for in a DTF gangsheet builder to maximize ROI?

Look for layout optimization with margins and bleed control, robust color management support and RIP compatibility, automation and queue management, user-friendly templates, and clear ROI evidence from vendor case studies and support quality.

What best practices help maximize results and avoid common pitfalls when using a DTF gangsheet builder for gangsheet printing efficiency?

Adopt pilots and templates for common product lines, maintain standardized color profiles, plan for white ink and overlays within gang sheets, and implement solid proofing and documentation. Avoid overcrowding gang sheets and ensure equipment compatibility among DTF sheets, transfer film, and printer drivers to sustain gangsheet printing efficiency.

| Aspect | Key Points |

|---|---|

| What is a DTF gangsheet builder? | Software/workflow tool that places multiple designs on a single large DTF sheet; increases designs per print; improves ink/film usage and press time; reduces setup changes. |

| Traditional sheet setups vs gangsheet | Prints one design per sheet or few designs with limited automation; can bottleneck at higher volumes. Gangsheet consolidates multiple designs, boosting throughput. |

| Efficiency benefits | Reduces load/unload cycles and color changes; shorter setup times; minimizes waste through better sheet packing; supports better color consistency across designs sharing color profiles. |

| Workflow integration & color management | Often integrates with RIP software and printers; can automate color separation, spacing, and alignment; requires compatible ecosystem for predictable results. |

| KPIs and ROI | Output per hour, material waste, ink usage, and setup time are key metrics. ROI improves with layout optimization, reduced waste, and stable color management. |

| Best practices | Run pilots to validate efficiency and color; build reusable gangsheet templates; use standardized color profiles and printer calibration; plan for white ink and overlays; document settings for repeatability. |

| Common pitfalls | Overcrowding designs on a sheet; inconsistent color management; underestimating setup time for new designs; equipment or driver incompatibilities causing rework. |

| Future trends | Increased integration with print management, real-time color matching, automated supply workflows, better e-commerce & MES compatibility, and advanced templates that adapt to various sizes and garments. |

Summary

The table above summarizes the key points about DTF gangsheet builders and how they compare to traditional sheet setups, highlighting efficiency gains, color management considerations, and best practices. This topic is central to optimizing DTF printing workflows for shops of any size.