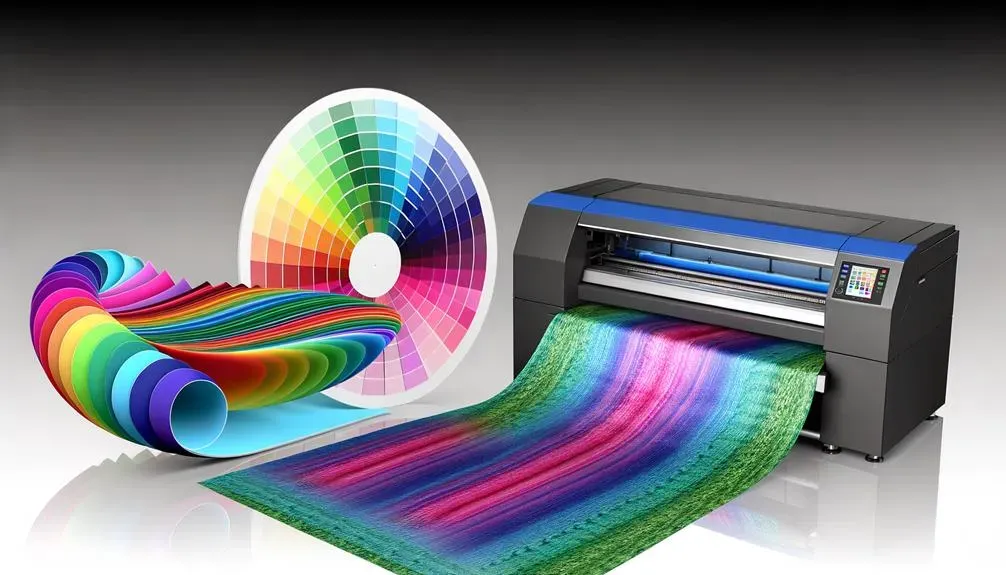

Color management in DTF printing is essential for translating digital designs into vibrant, accurate garments. A well-structured DTF color management approach reduces waste, shortens cycles, and builds trust with customers. By leveraging DTF color profiles and calibrated workflows, you can achieve CMYK color management for DTF that aligns with the original artwork. This also improves DTF print color accuracy across substrates and batches. In practice, a robust DTF printing workflow ties design space, device calibration, and substrate behavior into one repeatable process.

In other terms, achieving reliable color on garments hinges on disciplined color fidelity across different fabrics. Think in terms of color accuracy, profile-driven mapping, and calibration routines that keep an image looking the same from screen to shirt. Instead of relying solely on RGB to CMYK conversions, emphasize device-independent color management, soft proofing, and ICC profile-based projections that predict on-garment results. This Latent Semantic Indexing-inspired approach highlights related concepts such as color fidelity, gamut mapping, and substrate response to guide everyday color decisions. Applied together, these ideas support a predictable, audit-friendly workflow for achieving repeatable prints across substrates.

Color management in DTF printing: ensuring design intent translates to on-garment reality

Color management in DTF printing is the foundational discipline that translates digital design intent into tangible on-garment results. By treating color management as a core part of the DTF color management strategy, shops can align screen appearances with what lands on fabric, improving DTF print color accuracy across substrates and runs. The goal is to minimize guesswork and rely on reproducible workflows, so color stays consistent from design to delivery. This approach integrates color spaces, profiles, and a robust printing workflow to reduce waste and boost customer confidence.

A practical approach begins with recognizing the three pillars of DTF color management: devices (screens, printers, and substrates), profiles (ICC-based mappings), and workflow (the processes that tie everything together). When executed well, this framework reduces surprises at production and helps maintain predictable outcomes. By prioritizing color fidelity as a business requirement, you can repeatedly reproduce exact or near-exact colors across different fabrics and batches.

DTF color profiles and color spaces: choosing the right setup for consistency

DTF color profiles are the mathematical representations that tell your devices how to reproduce color consistently. Managing DTF color profiles means creating or obtaining ICC profiles for the monitor, printer, and substrate, then using them within a controlled workflow to minimize color shifts. With properly calibrated profiles, you can predict how a design will look when printed, improving overall DTF print color accuracy and reducing rework. The objective is to create a reliable map that preserves color intent across devices.

Color spaces matter because the design space you work in (often RGB on screen) must be translated into the printer’s usable space (commonly CMYK or a device-specific gamut). The conversion process depends on the quality of the profiles and the soft-proofing options you employ. Substrate characteristics, such as fabric color and transfer film, can further influence how colors shift, making precise color management essential for consistent results across productions.

Calibrating devices for reliable DTF printing workflow

Calibration is the first line of defense against color drift in a DTF printing workflow. Calibrating the monitor ensures what you see on screen closely matches the intended design, supporting accurate soft-proofing and minimizing the risk of unexpected shifts when the design lands on fabric. A hardware color calibrator helps establish a stable starting point for soft-proofing against the printer’s color profile, which is critical for achieving DTF print color accuracy across substrates.

Printer calibration involves printing a color targets chart on the actual substrate you’ll use in production and measuring results with a spectrophotometer or colorimeter. This step aligns the printer’s output with the profile, reduces drift over time, and supports repeatability. Maintaining a baseline of color targets for common designs and fabrics, and re-measuring periodically, ensures that calibration keeps pace with ink aging, environmental changes, and routine maintenance.

CMYK color management for DTF: mastering gamut and ink behavior

CMYK color management for DTF addresses the reality that RGB designs must be converted to a printer’s CMYK gamut. Choosing appropriate rendering intents ( Relative Colorimetric or Perceptual for many applications) helps preserve perceptual color fidelity during RGB-to-CMYK conversions. Understanding gamut limitations is crucial; some vivid blues, greens, or neons may fall outside the printer’s CMYK range, demanding compromises or the use of spot colors if your workflow supports them.

Inking behavior and substrate choice are fundamental to success in CMYK-based DTF printing. White ink interactions on dark fabrics can dramatically affect perceived brightness and contrast, so you must test how white underbase layers interact with your colors. Consistency also depends on stable ink loading and cartridge priming, ensuring uniform color density across runs to prevent shifts that degrade DTF color profiles and DTF print color accuracy.

DTF printing workflow: from design to delivery with color accuracy

A robust DTF printing workflow embeds color management at every stage, reducing variability and speeding turnaround. Start with design alignment to printer capabilities, ensuring that artwork uses a profile appropriate for the substrate. Soft proofing against a calibrated monitor helps verify saturation and legibility before committing to production, supporting a consistent DTF printing workflow.

The workflow continues with color conversion, test prints on representative substrates, and meticulous print preparation. Running nozzle checks and ensuring head alignment prevents color inaccuracies from hardware issues. After curing, a structured quality control step compares the final product to the intended color targets, guiding adjustments to profiles and print settings to strengthen DTF color management across future runs.

Troubleshooting color shifts and metamerism in DTF color management

Color shifts between batches are a common sign that the DTF color management system needs reinforcement. Metamerism, where colors appear different under varying lighting, is another frequent pitfall that can erode perceived color accuracy. In both cases, re-evaluating and updating DTF color profiles, refining soft-proofing setups, and ensuring consistent substrate handling can restore predictability.

Banding, dullness on dark fabrics, or unexpected saturation changes often point to calibration gaps or substrate-induced variability. Addressing these issues requires rechecking monitor and printer calibration, validating ICC profiles for each substrate, and adjusting conversion settings within the DTF printing workflow. Documenting changes and results helps reproduce successful configurations and serves as a reference when troubleshooting future color deviations.

Frequently Asked Questions

What is DTF color management and why is it important in the DTF printing workflow?

DTF color management aligns your screen, printer, ink, and substrate so the final on-garment colors match the design. It rests on three pillars—devices, profiles, and a repeatable DTF printing workflow. Implement calibration, color targets, and soft-proofing to reduce waste and ensure consistency across runs.

How do DTF color profiles influence CMYK color management for DTF?

DTF color profiles (ICC profiles for monitor and printer) govern how RGB designs are converted to the printer’s CMYK space. Proper calibration and profile creation minimize color shifts during RGB to CMYK conversions. Soft proofing and substrate-specific profiles help predict on-garment results.

What steps improve DTF print color accuracy across different fabrics?

Start with calibrated monitors and printers and establish a baseline color target. Create substrate-specific profiles to account for fabric color and ink absorption. Run small test prints and use soft-proofing to preview results before production.

What are common CMYK color management for DTF challenges and how can I address them?

CMYK limitations include gamut gaps for vivid blues or neons and white ink behavior on dark fabrics. Use perceptual or relative colorimetric intents during RGB-to-CMYK conversions and consider spot colors when your workflow supports them. Always test ink loading and white underbase interactions.

How should the DTF printing workflow be structured to ensure color consistency?

A robust workflow integrates color management at design, proofing, printing, and curing stages. Include design alignment with the printer profile, color conversion with soft proofing, and representative test prints. Regular nozzle checks and standardized lighting for quality control help maintain color fidelity.

What practical tips help maintain DTF color management and color accuracy over time?

Build a color library with representative swatches for each substrate. Schedule regular calibration and profile updates after substrate changes or ink updates. Document changes and re-measure periodically to catch drift and keep results repeatable.

| Aspect | Key Points |

|---|---|

| Introduction | Color management aligns screen-to-garment in DTF printing; essential for accurate reproduction and positive business outcomes. |

| Three Pillars | Devices (screen, printer, substrate), Profiles (ICC), and Workflow (end-to-end process) form the core of color management in DTF. |

| Profiles & Color Spaces | Use input device and printer ICC profiles; employ soft-proofing; manage RGB (design) to CMYK/device space conversions carefully to minimize shifts. |

| Substrate Influence | Garment color, fabric type, and transfer film affect reflectance and ink behavior; tailor profiles to substrate to minimize tonal changes. |

| Calibration | Calibrate monitor with hardware tools; calibrate printer with color targets on actual substrates; establish baselines and maintain them; use soft proofing when possible. |

| CMYK Management | When converting RGB to CMYK, choose rendering intents wisely; be mindful of gamut limits; manage white ink on dark fabrics; ensure consistent ink loading. |

| Workflow | Incorporate color management at design, proofing, test prints, production setup, curing, and final QC to reduce variability. |

| Practical Tips | Build a color swatch library; maintain substrate-specific profiles; schedule regular maintenance; document changes for reproducibility. |

| Common Issues | Expect batch-to-batch color shifts, banding, metamerism, and color loss on dark substrates; address via calibration, profiles, and process controls. |

Summary

HTML table created to summarize the key points of Color management in DTF printing.