UV DTF printing for small businesses is reshaping how brands, retailers, and makers bring custom apparel and promotional products to market, delivering vibrant, durable designs on demand with low minimums, minimal waste, and fast turnarounds that keep pace with evolving customer requests. To capitalize on this opportunity, it’s essential to understand the UV DTF printing process, how UV-curable inks interact with transfer films, and why DTF transfers for small businesses are becoming a practical, scalable option for prototyping, small runs, and on-demand fulfillment. From design through curing and finishing, adopting a start-to-finish DTF workflow helps you control color accuracy, maximize material efficiency, and shorten lead times, especially when supporting UV printing for apparel across a wide range of fabrics and substrates. When comparing methods, many teams weigh DTF vs. traditional transfer against DTG and screen printing, recognizing that UV DTF transfers can offer bold saturation on dark fabrics, crisper edges, and straightforward maintenance. With thoughtful process design, your small operation can scale confidently, delivering high-value products that build a loyal customer base and differentiate your brand in a crowded market.

In broader terms, this approach can also be described as UV-based ink-on-film transfers, a digital-to-fabric workflow that supports on-demand customization without large inventories. Other LSIs include on-demand apparel printing, color-managed transfer films, quick-turn garment printing, and durable, vibrant results across various fabrics. The underlying concept remains: designs are printed onto a film, then transferred to the substrate using heat, producing consistent results with less risk and faster iteration than traditional bulk methods. Framing the topic this way helps readers connect with the technology from different angles while keeping the focus on how flexible, scalable production can empower small businesses.

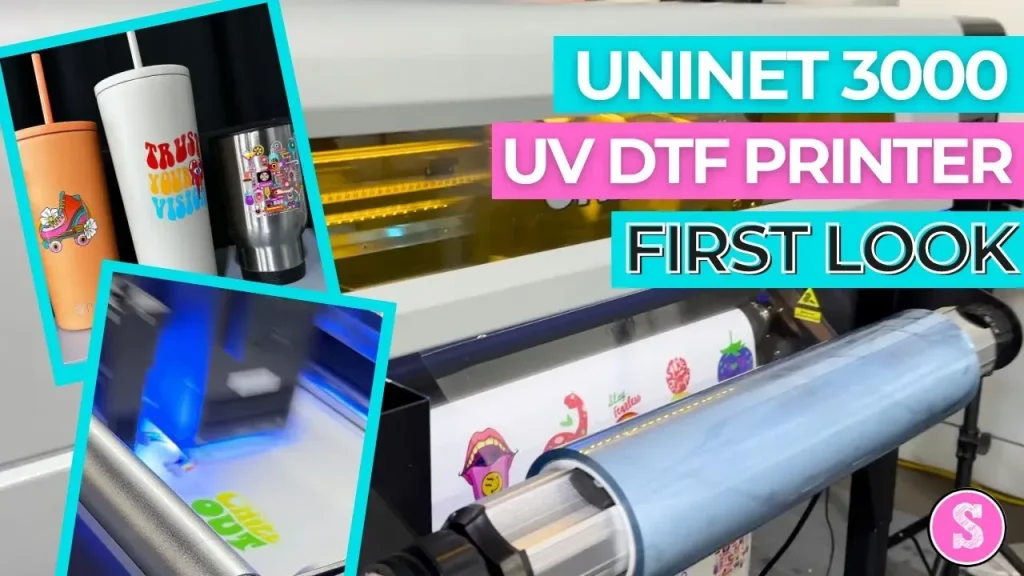

UV DTF printing for small businesses: transforming on-demand apparel and promotional products

UV DTF printing for small businesses enables on-demand customization of apparel and promotional items with minimal upfront investment. Brands can offer short-run designs, test campaigns, or fulfill last-minute orders without the burden of large inventories.

This approach relies on the UV DTF printing process and DTF transfers for small businesses to deliver vibrant, durable images on garments and other substrates. By leveraging heat-activated transfer films, you can produce sharp edges, rich color, and wash-fast results that survive regular wear.

Understanding the UV DTF printing process and its advantages for lean teams

The UV DTF printing process starts with artwork prepared for color management, followed by printing onto a specialized transfer film using UV-curable inks. The print is then dusted with an adhesive powder (if required), cured, and finally transferred to the garment via heat and pressure.

For lean teams, the process offers predictable throughput and flexibility. The ability to store designs digitally and reproduce them on demand aligns with a start-to-finish DTF workflow that minimizes waste and maximizes margins, especially when comparing UV printing for apparel against other transfer methods.

DTF transfers for small businesses: choosing the right workflow and equipment

Selecting the right equipment—UV-curable inks, a compatible DTF transfer film, an adhesive system, and a reliable heat press—sets the foundation for consistent results. When evaluating options, consider total cost per unit, print durability, and how easily you can scale up as orders grow for DTF transfers for small businesses.

A practical workflow also means investing in color management tools and design software tuned for UV inks. By aligning your equipment with a well-documented start-to-finish DTF workflow, you reduce reprints, minimize waste, and maintain stable output across runs.

Start-to-finish DTF workflow: from design to finished product for startups

A robust start-to-finish DTF workflow begins with design and prepress—using high-resolution artwork, proper ICC profiles, and alignment considerations for the transfer film. Organizing proofs and color checks up front helps ensure your final product looks as intended.

The workflow continues through printing, powdering (if used), curing, transfer, and finishing. Following a documented SOP keeps team members aligned, supports consistent color management, and makes scaling easier as demand grows.

UV printing for apparel: color management, texture, and durability

UV printing for apparel demands rigorous color management to maintain fidelity from screen to garment. Using ICC profiles and calibrated monitors helps align digital design intent with the vibrant results produced by UV-curable inks on transfer films.

Texture and opacity are also critical. White underbases or backers can improve vibrancy on dark fabrics, while careful tuning of print settings reduces banding in gradients. Proper curing and adhesive handling further contribute to durable, wash-fast transfers on apparel.

DTF vs. traditional transfer: when UV DTF shines for small teams and alternatives

DTF vs. traditional transfer comparisons emphasize speed, flexibility, and cost per unit. UV DTF printing often delivers quicker cures and robust color on a broader range of fabrics, making it attractive for small teams that need to turn designs into products rapidly.

For some use cases, DTG or screen printing may still be preferable, especially for large runs or specific material requirements. However, UV DTF transfers offer distinctive advantages for on-demand, customization-heavy offerings, effectively addressing the needs of small businesses while maintaining high print quality.

Frequently Asked Questions

What is UV DTF printing for small businesses and why is it valuable?

UV DTF printing for small businesses uses UV-curable inks on a DTF transfer film that is heat-pressed onto garments or other substrates. This approach enables on-demand production, low minimums, and fast turnarounds, while delivering vibrant color and durability. Compared with traditional transfers, it offers broad fabric compatibility, reduced inventory risk, and a practical start-to-finish workflow that minimizes waste and boosts margins.

How does the UV DTF printing process compare to traditional transfer methods for small businesses?

The UV DTF printing process relies on UV-curable inks printed on transfer film, followed by powdering (if required), curing, and transfer to the substrate. It often delivers stronger color, better wash durability on dark fabrics, and faster production cycles than traditional transfers, making it attractive for small runs and on-demand orders. Costs and setup considerations vary by equipment and materials, so a careful evaluation of total cost per unit is important.

What is a start-to-finish DTF workflow for UV DTF printing for small businesses?

A practical start-to-finish DTF workflow includes: 1) design and prepress with color management; 2) printing on the transfer film with UV inks; 3) powdering and curing if required; 4) transfer and garment preparation with proper heat and timing; 5) finishing and care guidance. Following these steps consistently helps achieve reliable results, reduces waste, and speeds up production for small teams.

What equipment and materials are essential for UV DTF printing for small businesses?

Essential items include a UV-curable DTF printer, UV-curable inks, DTF transfer film, adhesive powder and a curing system, a reliable heat press, a range of substrates, and design software with color management (ICC profiles). Investing in quality components and maintaining calibration helps ensure consistent color, strong adhesion, and durable transfers suitable for small-batch production.

How should a small business price and scale UV DTF transfers for growth?

Price UV DTF transfers by accounting for material costs (film, ink, powder), equipment depreciation, labor, and overhead. Use tiered pricing for volume, loyalty discounts for repeat customers, and bundles that include design or multiple items. Implement a simple order-management workflow to track proofs, production status, and shipping, and lean into on-demand fulfillment to minimize inventory risk.

What common challenges arise with UV printing for apparel and how can a small business mitigate them?

Common challenges include adhesion issues, color drift, smearing or ghosting, and edge brittleness. Mitigate these by regular printer and monitor calibration, maintaining a clean workspace, running routine test prints, ensuring proper curing and powder application, and using high-quality transfer film. Establish clear SOPs so your team can consistently reproduce reliable results as you scale.

| Topic | Key Points |

|---|---|

| What is UV DTF printing and why it matters for small businesses? |

|

| Core advantages for small businesses |

|

| Start-to-finish workflow: from design to finished product |

|

| Equipment and materials |

|

| Quality control and best practices for consistent results |

|

| Design and color considerations for UV DTF in small business contexts |

|

| Pricing, order management, and scaling for UV DTF offerings |

|

| Common challenges and how to handle them |

|

| UV DTF versus other transfer methods: a quick comparison for small businesses |

|

Summary

UV DTF printing for small businesses offers a powerful blend of flexibility, quality, and speed. By following a clear start-to-finish workflow—from design and prepress to printing, powdering, transfer, and finishing—you can deliver high-value products with consistent results. The key lies in careful color management, reliable equipment, and a culture of continuous improvement. With the right approach, UV DTF printing for small businesses can scale with demand, support diverse product lines, and help you stand out in a crowded market. As you iterate, keep testing, measuring, and refining your process so every transfer becomes a reliable match to your customer’s expectations and your brand promise.