The DTF Gangsheet Builder is an essential tool for anyone looking to elevate their printing capabilities in the ever-evolving world of Direct-to-Film (DTF) printing. This innovative software allows users to consolidate multiple designs onto a single transfer film, maximizing both ink utilization and material efficiency. With the right DTF gangsheet tips, you can streamline your workflow and enhance your overall print optimization efforts. In this guide, we will delve into effective design layout techniques and explore the intricacies of transfer film design to ensure your projects stand out. Whether you’re a seasoned professional or just beginning, mastering the DTF Gangsheet Builder is key to achieving vibrant, long-lasting prints and gaining a competitive edge in the custom apparel market.

Explore the intriguing world of DTF printing with the DTF Gangsheet Creator, a powerful resource designed to help you optimize your designs for enhanced printing results. This cutting-edge platform empowers users to efficiently arrange various graphics on a single transfer film, ultimately reducing waste and maximizing performance. By leveraging effective strategies around gangsheet layouts and understanding how to manipulate transfer film designs, you can significantly improve the quality of your prints. In this article, we will guide you through essential practices that enhance efficiency and quality, providing pathways to mastering your print projects like never before. Join us as we uncover crucial insights that will transform your approach to custom apparel printing.

Getting Started with DTF Gangsheet Builder Techniques

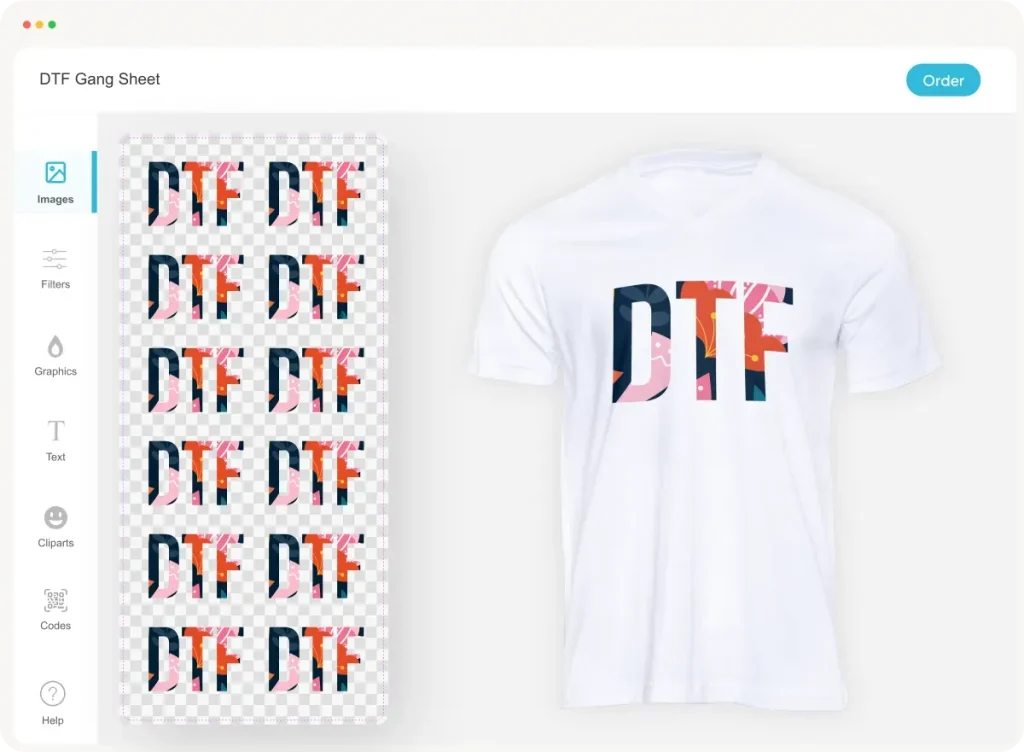

The DTF Gangsheet Builder is an essential tool for anyone involved in DTF printing. This innovative software allows users to maximize their transfer film by fitting multiple designs onto a single sheet. By organizing multiple graphics into a gangsheet layout, printers can achieve significant savings in ink and material costs, while also increasing the efficiency of their workflow. Understanding the initial setup of this builder and its features is crucial for leveraging its full potential.

When you first start using the DTF Gangsheet Builder, it’s important to experiment with its layout options. Familiarize yourself with how to adjust margins and spacing between designs. By exploring these features, you can create optimal arrangements that minimize waste while maximizing the area covered by your prints. A solid grasp of these initial techniques will set the tone for your printing processes and ensure that your designs are transferred cleanly and effectively.

Mastering DTF Printing Optimization

Optimal DTF printing requires a blend of technical skills and creative design ingenuity. By focusing on print optimization techniques, one can enhance the overall quality and durability of their prints. This might include using high-quality inks and transfer films, as well as ensuring that the design layout adheres to industry best practices. Critically assessing how ink distribution interacts with various textures will also yield impressive results.

Furthermore, fine-tuning your print settings can make a world of difference. Adjusting properties like saturation, contrast, and resolution based on the type of design and fabric you’re working with can empower your prints. Utilizing test prints for different variables will help establish the best configurations for achieving vibrant colors and fine details in your DTF projects.

Effective Design Layout Strategies

Design layout is paramount when using the DTF Gangsheet Builder to ensure that prints come out as expected. Arranging elements systematically not only enhances aesthetic appeal but helps you utilize space wisely. A well-structured layout can save on material costs and prevent wasted film during the printing process, making this a vital step in DTF printing.

Incorporating consistent sizing into your design layout can streamline production and minimize errors. Placing designs at uniform dimensions allows for easier scaling during output. Consider using software tools that allow you to create a template to experiment with placements before printing. This ensures that every element fits perfectly on the gangsheet without overlaps, resulting in a polished final product.

Ensuring Quality Control in DTF Printing

Quality control starts with the images you choose for printing. Ensuring that files are at least 300 DPI is essential to maintain crisp details and vibrant colors. Analyzing files for potential issues before sending them to print is a wise practice, as pixelation can profoundly affect the outcome of your DTF projects. Implementing a strict review process can help you identify and correct issues early.

Additionally, conducting routine test prints allows for the evaluation of color accuracy and print quality. This not only facilitates any necessary adjustments in design or materials but also leads to more consistent results across larger production runs. Engaging in this practice is vital to cultivating a reputation for high-quality DTF prints that your customers can rely on.

Choosing the Right Materials for DTF Printing

Selecting high-quality materials is essential for achieving premium results in DTF printing. The type of transfer film you choose can significantly impact print durability and vibrancy. Ensuring compatibility between your DTF film, inks, and the substrates used is critical in producing long-lasting prints that maintain color and integrity over time.

In addition, assessing the texture and composition of your chosen fabrics is imperative. Different substrates may react variably to DTF prints, affecting the adhesion quality and overall appearance. Therefore, conducting tests on a variety of materials will help you pinpoint the best combinations for your designs, ultimately leading to superior finished products.

Utilizing Software Features for Enhanced Printing

Harnessing the full potential of software automation tools can dramatically increase productivity in the DTF printing process. Many Gangsheet Builders offer features that automate design placement and settings based on specified parameters, which can streamline your workflow and minimize manual errors. Keeping abreast of these tools can ensure you’re utilizing the most modern advantages in the industry.

Moreover, color management capabilities within printing software are crucial for achieving consistent results. By establishing color profiles that align closely with the final output, you reduce discrepancies between print and digital versions. This integrated approach not only enhances your workflow but also elevates customer satisfaction by delivering exactly what clients expect.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a tool designed for Direct-to-Film (DTF) printing that allows users to arrange multiple designs on a single transfer film, optimizing ink usage and reducing material waste. By maximizing design placement, print shops can increase efficiency and reduce costs while achieving high-quality prints.

How can I optimize design layout using the DTF Gangsheet Builder?

Optimizing design layout with the DTF Gangsheet Builder involves efficient space management, ensuring designs are placed close together while maintaining sufficient margins. Software like Adobe Illustrator can help visualize your layout, enabling better use of transfer film and preventing overlaps.

What are some essential DTF gangsheet tips for achieving high-quality prints?

To achieve high-quality prints using the DTF Gangsheet Builder, ensure all design images are at least 300 DPI to avoid pixelation. Conducting test prints is also crucial for verifying color accuracy and material compatibility before mass production.

Which materials are best suited for DTF printing with the Gangsheet Builder?

When using the DTF Gangsheet Builder, it’s important to choose high-quality DTF films and adhesives that are compatible with your printer and fabrics. Testing various substrates will help determine which materials yield the best results in terms of vibrancy and durability.

How does color management play a role in DTF Gangsheet printing?

Color management is vital in DTF printing as it ensures that the colors displayed on your monitor match the final prints. Utilizing the color profiling features of your DTF Gangsheet Builder software minimizes discrepancies, enhancing customer satisfaction.

What post-printing techniques should I follow after using the DTF Gangsheet Builder?

After printing with the DTF Gangsheet Builder, it’s essential to properly cure the prints to ensure they adhere well to the fabrics. Additionally, providing customers with clear care instructions will help prolong the lifespan of the prints, preventing fading and wear.

| Key Aspect | Tips and Insights |

|---|---|

| Understanding DTF Gangsheet Technology | Arranging multiple designs on one transfer film optimizes ink use and reduces waste. |

| Optimize Design Placement | Manage space effectively between designs and maintain size consistency to improve workflow. |

| Quality Control | Use high-resolution images and conduct test prints for quality assurance. |

| Choosing the Right Materials | Select high-quality films and adhesives; be aware of substrate compatibility. |

| Utilize Software Features | Take advantage of automation tools and color management settings in the Gangsheet Builder. |

| Post-Printing Process | Familiarize yourself with proper curing techniques and provide customers with care instructions. |

Summary

DTF Gangsheet Builder is an essential tool for anyone looking to enhance their printing capabilities in the custom apparel market. By mastering the techniques outlined above, such as effective design placement, stringent quality control, and strategic material selection, you can dramatically elevate your printing game. Implementing advanced software features and understanding the post-printing processes will further ensure superior results. Embracing these practices not only boosts your efficiency but also elevates the quality of your product, leading to greater customer satisfaction and a strong competitive edge.