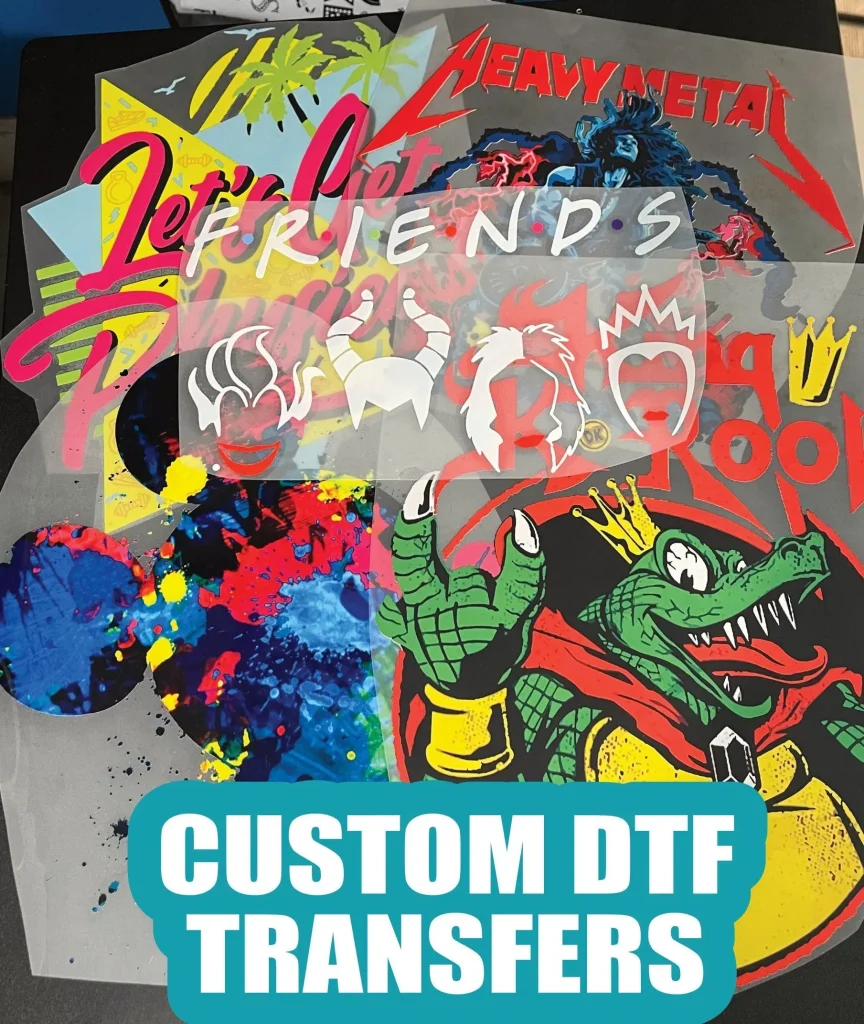

DTF Transfers, or Direct-to-Film transfers, represent a dynamic breakthrough in the printing landscape, particularly in the textile industry. As businesses and creatives seek innovative ways to produce high-quality fabric prints, DTF printing emerges as a highly effective method that combines vibrant designs with remarkable detail. This technique not only enhances the aesthetic appeal of garments, but also offers a cost-effective alternative to traditional printing methods. In this blog, we will unpack the myriad of DTF printing benefits, explore the essential DTF transfer process, and examine the various techniques that ensure perfect prints every time. Join us as we delve into the world of DTF prints and discover how they can elevate your printing projects to new heights.

Direct-to-Film printing, commonly referred to as DTF printing, is revolutionizing the way we create designs for apparel and textiles. This modern printing process allows for seamless transfer of intricate images onto fabrics, offering versatility that many traditional methods lack. From custom apparel to promotional products, the advantages of this technique are becoming increasingly apparent. In exploring the various DTF printing techniques, one can appreciate the significant benefits, including the production of high-resolution prints and a more eco-friendly approach. Dive deeper with us as we uncover how this cutting-edge printing approach is shaping the future of fabric printing.

Understanding the DTF Printing Process

DTF printing is an innovative process that involves printing designs onto a specialized film, which is then transferred onto fabric using a heat press. This technique stands out due to its capability to print intricate designs with striking colors on various surfaces, which is not always feasible with traditional screen printing. The DTF transfer process ensures that images are not only vibrant but also durable, making them resilient to wear and tear. As industries continue to embrace customization, understanding the DTF printing process becomes vital for manufacturers seeking to meet client demands.

The DTF transfer process significantly reduces waste and enhances print precision, allowing for adjustments that cater to specific fabric types. Businesses can utilize this technology across cotton, polyester, and blends without compromising quality, setting a new standard in the realm of printing. Additionally, operators can achieve distinct outcomes by selecting the right inks and transfer films, positioning DTF as a versatile choice for many applications, from fashion to promotional materials.

Benefits of Using DTF Transfers for Businesses

The transition to DTF transfers offers numerous benefits for businesses looking to enhance product quality and reduce operational costs. One of the primary advantages is the high-quality fabric prints that DTF technology affords. Unlike traditional methods that often struggle with detail and color saturation, DTF printing excels at producing professional-grade designs that stand out in a crowded market. This level of quality not only elevates the final product but also boosts customer satisfaction and enhances brand reputation.

Furthermore, DTF transfers provide a cost-effective solution for businesses, particularly those operating on smaller scales or custom orders. The initial setup costs are lower when compared to traditional printing methods, allowing companies to experiment with a range of products without significant financial investment. This advantage is particularly appealing to startups looking to establish their presence in the competitive textile market, enabling them to offer unique and customized apparel without the typical overhead associated with conventional printing processes.

Exploring DTF Printing Techniques

To achieve the best results in DTF printing, several techniques must be mastered. Calibration of printers is paramount to ensuring that colors are reproduced accurately. Regular maintenance of the printing devices also plays a critical role in preventing malfunctions and ensuring consistent print quality across batches. Coupled with this is the importance of selecting high-quality films that can withstand the rigors of washing and daily use, ensuring that the prints do not fade or peel over time.

Additionally, proper pretreatment of fabrics before the DTF transfer process is essential. By applying a pretreatment solution, businesses enhance the adhesion between the print and the material, resulting in designs that remain intact through multiple washes. Attention to detail in the application process—such as adjusting heat press settings for different fabric types—can make a significant difference in the final appearance of the product. These techniques, when executed correctly, lead to vibrant prints that exceed expectations.

The Versatility of DTF Transfers Across Materials

One of the standout features of DTF transfers is their versatility when it comes to application across various materials. Unlike traditional screen printing, which may have limitations regarding the types of fabrics that can be printed, DTF technology allows for a broad range of options. From cotton to polyester, and even blends, DTF transfers can adapt to meet diverse customer preferences, making them an ideal choice for custom apparel and promotional merchandise.

This adaptability also opens new avenues for creative expression in fashion, as designers can explore different textiles and substrates without fear of losing print quality. As consumers increasingly seek unique and personalized products, businesses can leverage the versatility of DTF printing to tap into niche markets, providing tailored solutions that appeal to specific demographics. This flexibility is a game changer in the rapidly evolving landscape of the textile industry.

Eco-Friendly Innovations in DTF Ink Technology

The move toward more sustainable printing practices has gained traction in recent years, and DTF printing is no exception. Many manufacturers are now focusing on developing eco-friendly inks that reduce environmental impact while maintaining the high-quality standards expected of prints. These inks are typically water-based, minimizing the use of harmful solvents and chemicals that can damage both the ecosystem and printer operators’ health.

By choosing environmentally friendly DTF inks, businesses can appeal to an increasingly eco-conscious consumer base. This alignment with sustainable practices not only benefits the planet but also positions brands as leaders in responsible production. As eco-friendly innovations continue to emerge in DTF printing, the potential for creating stunning, sustainable designs becomes limitless, catering to the needs of a market that values both quality and environmental stewardship.

Future Trends in DTF Printing Technology

As DTF printing technology continues to evolve, new trends are emerging that promise to refine the process even further. Enhanced printer models are being developed with integrated systems designed to streamline maintenance and improve print speeds. With the growing demand for faster turnaround times in a competitive industry, these advancements are essential for businesses looking to stay ahead of the curve.

Moreover, advancements in ink formulations are set to enhance print vibrancy while shortening cure times, making the process even more efficient. By adopting these innovative solutions, businesses leveraging DTF printing will find themselves better equipped to meet customer demands for quality, speed, and sustainability. As technological innovations unfold, the future of DTF printing looks bright, ensuring its role as a cornerstone of modern textile printing.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film Transfers, involve printing designs onto a special film that is then heat applied to a fabric. This process creates vibrant and detailed images, making it an innovative technique in the textile printing industry.

What are the primary benefits of using DTF transfers for fabric printing?

The primary benefits of DTF transfers include high-quality fabric prints, versatility with different materials, cost-effective setup, and user-friendly processes. This method ensures that intricate designs are produced with rich colors and durability.

How does DTF printing compare to other techniques like screen printing?

DTF printing offers several advantages over traditional screen printing, such as greater design complexity, the ability to print on various fabrics, and a more cost-effective setup, making it suitable for small businesses and custom projects.

What techniques help achieve perfect DTF prints?

To achieve perfect DTF prints, it’s essential to calibrate printers correctly, use high-quality transfer films, conduct proper pretreatment of fabrics, optimize heat press settings, and select quality DTF inks to enhance print durability and vibrancy.

Are DTF transfers considered eco-friendly?

Yes, many DTF inks are water-based, making them a safer and more eco-friendly choice compared to solvent-based inks. This sustainability aspect appeals to environmentally conscious businesses and consumers alike.

What innovations are shaping the future of DTF printing technology?

Recent innovations in DTF printing technology include advanced ink formulations that improve print vibrancy and durability, enhanced printer models with integrated systems for better performance, and a growing market demand for customizable apparel solutions.

| Key Points | Explanation |

|---|---|

| What is DTF Printing? | DTF printing is a process of printing designs onto a special film which is then transferred onto apparel fabric. It produces vibrant and detailed images, outperforming traditional printing methods. |

| Benefits of DTF Transfers | Includes high-quality prints, versatility with materials, cost-effective setup, user-friendly process, and eco-friendly options. |

| Key Techniques for Perfect Prints | Involves printer calibration, quality of film, pretreatment steps, expertise with heat press settings, choice of quality inks, and post-press care. |

| Recent Developments in DTF Technology | Includes innovations in ink formulations, enhanced printer models, and increasing market demand for customization in apparel. |

Summary

DTF Transfers have emerged as a transformative solution in the printing industry, providing exceptional print quality and flexibility. Understanding DTF Transfers allows businesses and creatives to leverage state-of-the-art technology in textile and apparel production. The advantages of DTF printing, such as its ability to deliver high-resolution graphics on diverse fabrics, significantly enhance customization options for brands. As the market for DTF continues to grow, keeping abreast of the latest techniques and innovations ensures competitive advantage and client satisfaction.