DTF transfers, or Direct-to-Film transfers, are transforming the landscape of custom apparel printing, bringing with them a wave of innovative fabric printing technology that caters to both quality and versatility. This modern method enables stunning designs to be printed onto films that can be seamlessly transferred onto various fabric types, making it a popular choice for many apparel businesses today. With sustainability becoming a key focus within the industry, DTF transfers are also leading the charge as an eco-friendlier option, reducing waste and offering faster turnaround times compared to traditional printing methods. As textile printing innovations continue to emerge, understanding how DTF transfers work and their benefits is essential for anyone involved in fabric decoration. In this post, we will delve deeper into the advantages and future potential of this exciting printing technology.

Direct-to-Film printing represents a significant breakthrough in the world of textile application methods, showcasing an evolution in how designs are applied to fabric surfaces. This technique is not only paving the way for enhanced custom apparel options but also stands out among various fabric decorating methods as a highly efficient and sustainable choice. Known colloquially as DTF transfers, this approach effectively bridges the gap between traditional printing limitations and the versatile demands of modern fashion. With its ability to produce high-quality prints quickly, the adoption of this technology is indicative of rising trends in the apparel industry that prioritize speed, quality, and environmental consciousness. As we explore the mechanics and advantages of DTF transfers, it is important to consider how these advancements are reshaping the future of fabric printing.

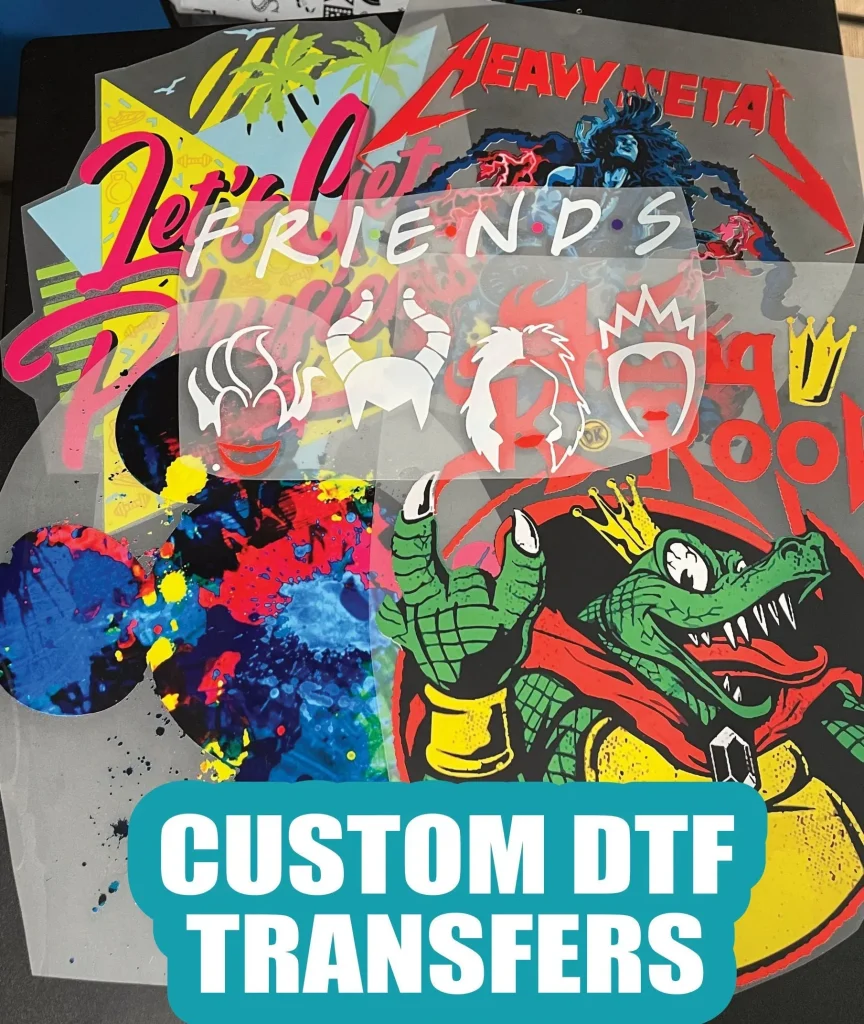

The Technology Behind DTF Transfers

Direct-to-Film (DTF) transfers represent a significant advancement in fabric printing technology, marrying digital printing precision with the versatility of traditional methods. DTF printing works by printing designs onto a special film, which can then be heat-pressed onto fabric. This process involves the use of high-quality inks that create vibrant colors and sharp images, ensuring that the final product not only looks stunning but also maintains its integrity over time. Unlike other methods, such as Direct-to-Garment (DTG) or screen printing, DTF does not require complicated setups, which streamlines the production process and reduces overhead.

Moreover, DTF transfers are engineered to be compatible with a variety of textile types. From cotton to polyester blends, the technology accommodates both light and dark fabrics, providing greater flexibility for custom apparel printing. This adaptability is particularly beneficial in a dynamic industry where consumer preferences and fashion trends shift rapidly. Manufacturers are leveraging advancements in DTF technology to push the envelope, offering features that enhance printing speeds and output quality, thus reinforcing DTF’s position as a leader in textile printing innovations.

Advantages of DTF Transfers in Custom Apparel

The advantages of DTF transfers extend beyond mere technological improvement; they represent a paradigm shift in how custom apparel is produced. One compelling advantage is the cost-effectiveness that DTF printing offers to businesses, especially those that engage in print-on-demand services. Traditional printing methods often involve significant upfront costs for materials and setup. In contrast, DTF transfers provide a more accessible entry point for small businesses looking to capitalize on the customization trend without the financial burden often associated with large production runs.

Quality is another pillar of DTF transfers’ growing popularity. The printing process produces vibrant, detailed designs that resist fading and cracking, ensuring that products maintain a fresh appearance even after multiple washes. This durability is essential for meeting consumer expectations in a competitive market. As sustainability increases in importance, DTF’s efficient printing practices result in less wasted material and energy compared to traditional methods, making it a more eco-friendly option for brands focused on sustainable printing methods.

DTF Transfers and Market Trends

The rise of DTF transfer technology aligns perfectly with current market trends that emphasize customization and uniqueness in fashion. As consumers increasingly seek personalized products, DTF printing enables brands to respond quickly to these demands, producing small batches of custom apparel with minimal lead time. This agility is critical in a fast-paced industry where trends can change overnight. Furthermore, as more businesses adopt DTF technology, competition is likely to drive prices down, making custom apparel more accessible to a broader audience.

Industry experts highlight that the DTF technique not only enhances production efficiency but also supports an emerging culture of personalization within the apparel sector. The ability for brands to create unique, individualized products on demand is fostering a deeper connection between consumers and brands. Additionally, as awareness of sustainable printing methods grows, DTF printing’s relatively low environmental impact sets it apart as a future-forward choice for conscientious manufacturers.

Challenges Faced by DTF Transfer Adoption

While the benefits of DTF transfers are numerous, potential adopters face certain challenges that might inhibit their transition to this technology. Initial costs for specialized equipment and inks can be significant, posing a barrier for small businesses or startups that may be operating on a tight budget. Additionally, while DTF transfers offer versatility, achieving the best results requires careful calibration of heat and time during the application process, necessitating a learning curve for operators accustomed to traditional printing methods.

Moreover, as the technology evolves, there may be ongoing challenges related to ensuring the quality and durability of prints. As more DTF printers become available, differences in production quality can lead to inconsistencies. However, as the industry matures and manufacturers refine their processes, these issues are likely to diminish. Entrepreneurs venturing into the DTF space must remain committed to investing in quality control to ensure their products meet the high standards that modern consumers expect.

Sustainability in DTF Transfers

The growing focus on sustainability in textile printing is a fundamental reason behind the rapid adoption of DTF transfers in the industry. Compared to traditional fabric printing methods, DTF transfers require less energy and fewer resources, making them a more eco-conscious choice for businesses. The streamlined process not only reduces waste material from screens and setups but also minimizes water usage, aligning with the textile sector’s increasingly stringent environmental standards.

Furthermore, brands that prioritize sustainable printing methods can appeal to a burgeoning demographic of eco-conscious consumers. By opting for DTF transfers, businesses can market their products as part of a sustainable fashion initiative, enhancing their image while also ensuring compliance with environmental regulations. As customers become more aware of the environmental impacts of their purchases, companies leveraging DTF technology can position themselves as leaders in the movement towards greener production practices.

The Future of DTF Transfers in the Fabric Printing Industry

Looking to the future, DTF transfers are poised to become even more integral to the fabric printing industry. As innovations in printing technology continue to emerge, the capabilities of DTF printing are expected to expand. This could result in even greater improvements in printing speed, color fidelity, and substrate versatility, further cementing its position as a preferred choice among manufacturers and apparel brands.

With the technology gaining momentum and acceptance across various segments of the market, businesses that adopt DTF transfers now may find themselves well ahead of the competition. The ability to fulfill changing consumer demands swiftly and sustainably is a great advantage, particularly in the wake of a growing emphasis on personalized and custom products in the textile and fashion sectors. As such, mastering DTF transfers is not just a trend; it is an essential strategy for future success in fabric printing.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, utilize a unique printing process to apply high-quality graphics onto a special film. This film can then be transferred to various fabrics, making DTF a versatile option in custom apparel printing. Unlike traditional methods, DTF printing bypasses the need for screens, allowing for efficient, detailed, and vibrant designs on fabric.

What are the benefits of using DTF Transfers for custom apparel printing?

DTF Transfers offer several benefits for custom apparel printing, including enhanced versatility for different fabric types, cost-effectiveness due to reduced setup times, impressive print quality with vivid colors, durability that withstands washing, and quick turnaround times crucial for fulfilling rapid demand in the fashion industry.

How does DTF Transfers compare with other fabric printing technologies?

DTF Transfers stand out when compared to other fabric printing technologies, such as screen printing and Direct-to-Garment (DTG). While screen printing requires complex setups and is less versatile, and DTG is limited in fabric compatibility, DTF is adaptable to various materials and delivers high-quality prints efficiently, making it a preferred choice in textile printing innovations.

Are DTF Transfers a sustainable printing method?

Yes, DTF Transfers can be considered a sustainable printing method. DTF printing requires less energy and material setup compared to traditional printing methods. As businesses seek to adopt sustainable printing methods, DTF technology aligns with the growing consumer preference for eco-friendly practices in the apparel industry.

What challenges should businesses consider when adopting DTF Transfers?

While DTF Transfers present many advantages, businesses must acknowledge some challenges, such as the need for specialized heat press equipment and specific inks, which can initially be costly. Additionally, achieving optimal results requires careful control over the heat transfer conditions, necessitating knowledge and expertise in the printing process.

What future trends can we expect with DTF Transfers in the textile printing industry?

The future of DTF Transfers looks promising as the demand for customized apparel increases. Predictions suggest that advancements in DTF printing technology will continue, making the processes faster and more cost-effective. As more entrepreneurs recognize the potential of DTF for custom fabric printing, we can anticipate widespread adoption and further innovations in this area.

| Key Features | Details |

|---|---|

| Definition | A modern printing technique where designs are printed onto a film that transfers to fabric. |

| Versatility | Works on various fabric types, including light, dark, and stretchy materials. |

| Cost Efficiency | Eliminates setup costs associated with traditional methods, ideal for small businesses. |

| Quality and Durability | Produces vibrant, long-lasting prints resistant to washing. |

| Production Speed | Facilitates quick turnaround times to keep up with fashion trends. |

| Market Insights | Growing demand for customized apparel and a shift towards sustainability. |

| Challenges | Requires investment in specific equipment and attention to transfer conditions. |

Summary

DTF Transfers are revolutionizing the fabric printing industry, providing a unique blend of versatility, cost-effectiveness, and high-quality output. As brands cushion their foothold in the competitive market, DTF Transfers have emerged as a crucial innovation that addresses the pressing demands of modern apparel printing. With their ability to effectively cater to a variety of fabric types, DTF Transfers not only enhance design possibilities but also ensure durability and speed—qualities essential for the fast-paced world of fashion. Looking ahead, as technology continues to improve, DTF Transfers are set to become increasingly accessible to businesses of all sizes, solidifying their position as a premier choice in the fabric printing landscape.