DTF Gangsheet Builder is revolutionizing the way custom apparel is produced, offering both businesses and creatives an innovative approach to design and print. With the rise of Direct-to-Film (DTF) printing technology, mastering this software empowers users to create stunning gangsheet designs that yield high-quality prints efficiently. The intuitive functionality of the DTF Gangsheet Builder allows for seamless alignment of multiple designs, ensuring no material is wasted in the process. This exceptional tool not only enhances the printing experience but also optimizes the use of transfer film, making it a favorite among professionals in the industry. As you delve into the world of DTF printing, understanding the capabilities of the DTF Gangsheet Builder is essential for producing remarkable, vibrant apparel.

In the realm of custom garment creation, the DTF Gangsheet Builder serves as a vital tool for digital textile printing enthusiasts. This innovative software streamlines the design and printing process, allowing users to craft multi-design layouts for efficient production. Utilizing advanced DTF printing methods, it facilitates the transfer of vibrant images onto fabric via specialized transfer film. Such capabilities make it an indispensable resource for anyone looking to achieve high-quality prints with minimal waste. By mastering gangsheet design through this powerful application, designers can significantly elevate their printing projects, achieving exceptional results every time.

The Benefits of DTF Printing for Custom Apparel

DTF printing has revolutionized the custom apparel industry with its innovative approach that combines efficiency and quality. One of the key benefits of DTF printing is its ability to produce vibrant and detailed designs that transfer exceptionally well onto various fabric types. Unlike traditional printing methods, DTF printing utilizes water-based inks that are not only eco-friendly but also provide a softness to the final print, ensuring a comfortable feel on the garment. This makes it an attractive option for businesses looking to offer high-quality prints that stand out.

Moreover, DTF printing allows for short production runs without compromising on quality. Whether you’re a small business owner or a hobbyist, this versatility means you can experiment with different designs and customizations without heavy financial investments. The ability to use a gangsheet design further maximizes material usage, keeping production costs low while still achieving professional-grade outcomes. In essence, DTF printing is not just a trend; it’s a sustainable solution for high-quality apparel decoration.

Getting Started with the DTF Gangsheet Builder

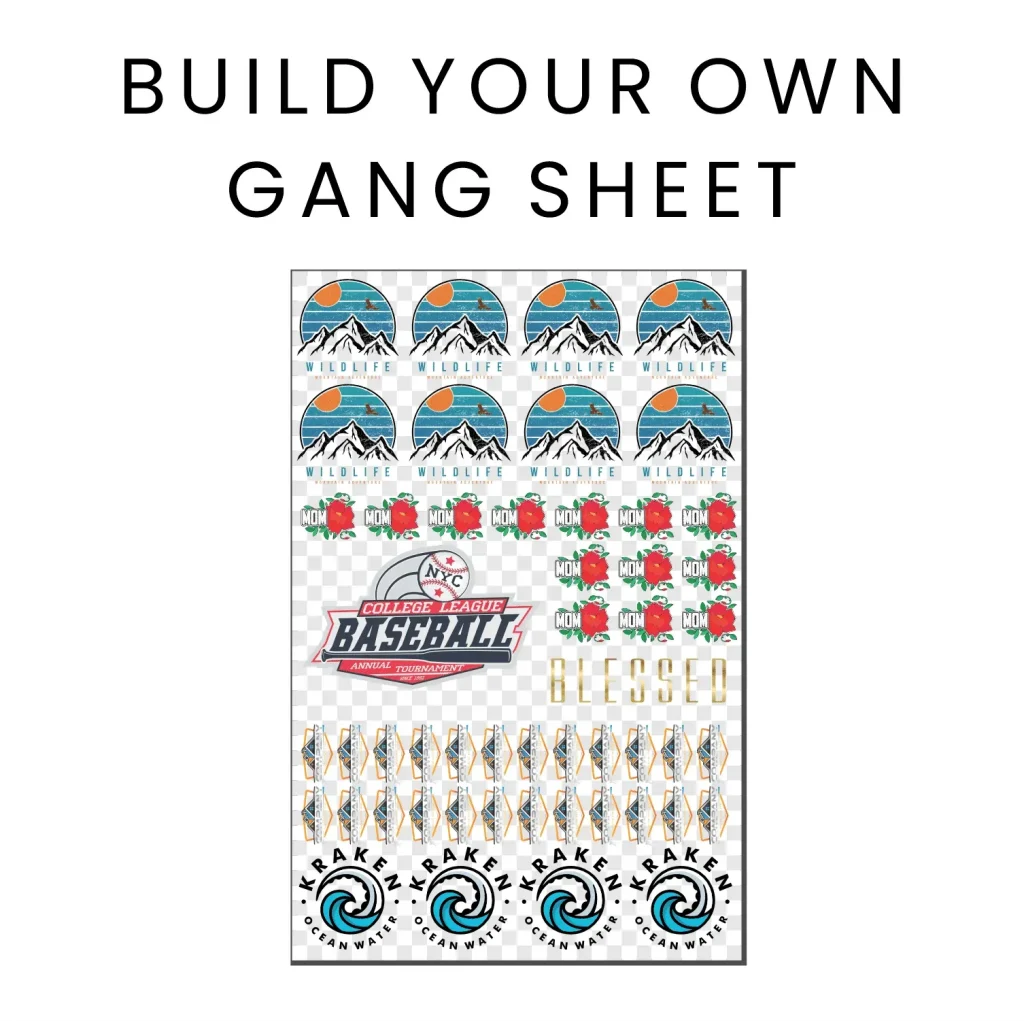

To begin your journey into DTF printing, familiarizing yourself with the DTF Gangsheet Builder is essential. This specialized tool is designed to help you efficiently layout multiple designs on a single sheet, reducing waste and optimizing your printing process. When starting, take the time to explore its features, such as aligning images, adjusting sizes, and utilizing preset templates that can simplify the design experience. Understanding these elements will significantly enhance your workflow and the quality of the final product.

Additionally, leveraging the DTF Gangsheet Builder can help streamline your production by allowing for easy adjustments and real-time previews of your layouts. This not only saves time but also ensures that every design is ready for printing without any last-minute surprises. The combination of careful planning and effective use of the Gangsheet Builder can lead to impressive results, making your prints not only eye-catching but also professionally finished. Remember, practice is key, and mastering this tool can elevate your sublimation game.

Choosing the Right Printing Software for DTF

Selecting the right printing software is crucial when working with DTF printing. Programs like Adobe Illustrator and CorelDRAW are popular among professionals due to their robust features that facilitate intricate designs and precise layouts. These software options enable users to create and manipulate vector graphics, which are essential for producing high-quality prints that are easily scalable without loss of resolution. Understanding how to navigate these platforms will enhance your ability to utilize the DTF Gangsheet Builder effectively.

In addition, many of these software solutions come equipped with tools that help in preparing images for transfer film, such as color management features and templates specifically for gangsheet design. Investing time in learning the intricacies of your chosen software will not only boost your design efficiency but also ensure that your DTF prints reflect the quality you aspire to achieve. With the right digital tools, you can unlock a world of creative possibilities that make your custom apparel truly unique.

Essential Tips for Designing Effective Gang Sheets

Designing effective gang sheets is fundamental to optimizing your DTF printing process. One essential tip is to maintain consistency in design sizes and spacing between images. This ensures that all elements fit neatly within the dimensions of the transfer film, minimizing the risk of overlap that can lead to wasted material. By sticking to a grid layout or using specific design templates, you can achieve a more organized and visually appealing gang sheet that maximizes the use of your transfer film.

Another important factor to consider is color management. Utilizing the CMYK color mode during the design phase can greatly improve the accuracy of colors once printed. Inconsistencies in color profiles may lead to unexpected results, and attention to detail here cannot be overstated. By ensuring that your designs are in the correct color space and accurately spaced, you can enhance the transition from screen to fabric, resulting in higher satisfaction rates with your printed apparel.

Steps to Prepare for DTF Printing

Preparation is key in the DTF printing process, and taking the right steps will set you up for success. Start with material selection; choosing the appropriate transfer film is crucial, as different fabrics can have varying adhesive properties. The compatibility of the transfer film with the garment will affect the adhesion and durability of the print, so ensure you choose wisely based on the end-use of your products.

In addition, adjusting your printer settings for DTF printing is vital for achieving optimal results. This includes configuring ink types and print resolution to ensure clarity and detail in every print. Paying attention to these settings not only affects the print quality but can also streamline your production process, allowing for quicker turnaround times without sacrificing the final product’s integrity.

Testing and Fine-Tuning Your Prints

Before moving to full production with DTF printing, it’s crucial to conduct test prints. This step is essential for identifying possible issues such as color discrepancies or misalignment before they become costly mistakes. Conducting sample tests allows you to verify that your designs are accurately represented and also gives you the opportunity to make necessary adjustments to your gangsheet layouts.

Fine-tuning your prints through test runs can mean the difference between a mediocre product and one that accurately reflects your vision. This proactive approach ensures that your final outputs not only meet your expectations but also resonate with your audience, leading to higher satisfaction rates and repeat customers. Ultimately, investing time in the testing process pays off by enhancing the quality and precision of your DTF prints.

Post-Printing Processes for Optimal Results

After the printing process, ensuring that your prints undergo the proper post-printing processes is crucial for long-lasting results. One vital step is the application of adhesive powder on the printed film. This step must be completed uniformly to ensure that the adhesive binds well with the fabric during the curing process. Inconsistencies in powder application can lead to weak adherence, risking the quality and longevity of your final product.

Curing is another essential step that requires attention to detail. Following the manufacturer’s guidelines for heating the printed film is critical; improper curing can compromise the integrity of the adhesive and, consequently, the print’s durability. By adhering to best practices in the post-printing phase, you ensure that your DTF printed garments are not only aesthetically pleasing but also resilient against everyday wear and washing, ultimately enhancing customer satisfaction.

Frequently Asked Questions

What is the function of the DTF Gangsheet Builder in the DTF printing process?

The DTF Gangsheet Builder is a specialized tool used in DTF printing that helps in arranging multiple designs on a single sheet, known as a gangsheet. This software optimizes material usage and layout, ensuring that designs are properly aligned and spaced for high-quality prints and efficient production.

How can I achieve high-quality prints using the DTF Gangsheet Builder?

To achieve high-quality prints using the DTF Gangsheet Builder, ensure all images are at least 300 DPI, utilize CMYK color mode for accurate color representation, and make proper use of the Builder’s templates for consistent alignment. Testing your prints beforehand also helps in identifying any adjustments needed.

What software options work best with the DTF Gangsheet Builder for designing prints?

Popular software options for designing prints that integrate well with the DTF Gangsheet Builder include Adobe Illustrator and CorelDRAW. These programs enable designers to create vibrant graphics and optimize gangsheet layouts effectively.

How does material selection impact DTF printing results with the Gangsheet Builder?

Material selection is crucial in DTF printing, as different transfer films have varying adhesion properties and flexibility. Choosing the right film based on the fabric will significantly influence the final print quality achieved through the DTF Gangsheet Builder.

What are the essential steps before using the DTF Gangsheet Builder for printing?

Before utilizing the DTF Gangsheet Builder, ensure proper preparation: choose the appropriate transfer film for your fabric, adjust printer settings for DTF printing, and verify designs through test prints to check color accuracy and placement.

Can I find tutorials on how to use the DTF Gangsheet Builder effectively?

Yes, you can find numerous tutorials on platforms like YouTube that demonstrate how to effectively utilize the DTF Gangsheet Builder. These resources provide step-by-step guidance on software usage, design techniques, and best practices in DTF printing.

| Key Aspect | Details |

|---|---|

| DTF Printing | An innovative method that uses water-based inks and transfer films for vibrant designs. |

| Software Choice | Popular programs include Adobe Illustrator and CorelDRAW for effective graphic design. |

| Design Layout | Arrange multiple designs to optimize material usage and reduce waste. |

| Color Accuracy | Use CMYK color mode for print consistency with on-screen designs. |

| Gangsheet Builder Use | Ensure DPI consistency and utilize templates for better alignment. |

| Prepping for Print | Choose appropriate transfer film and adjust printer settings for optimal results. |

| Testing Prints | Conduct test prints to check color accuracy and placement. |

| Post-Printing Process | Apply adhesive powder and follow curing guidelines to ensure quality. |

| Further Resources | Blogs, magazines, and video tutorials for deeper understanding of DTF. |

Summary

The DTF Gangsheet Builder serves as an invaluable tool in the realm of custom apparel production, allowing users to maximize their design efficiency and print quality. By mastering this tool, whether as a beginner or a seasoned professional, you can create stunning and vibrant designs that stand out. From understanding the intricacies of DTF printing to leveraging the right software and design techniques, this guide emphasizes the importance of preparation, precision, and continuous learning in achieving exceptional results. The benefits of utilizing the DTF Gangsheet Builder not only streamline your production process but also elevate the quality of your apparel, making it an essential component for success in this competitive industry.