In the dynamic landscape of custom design, **DTF transfers** are emerging as a game-changing technology that empowers creators to bring their artistic visions to life with remarkable precision and vibrancy. This innovative approach, short for Direct Transfer Film, combines the ease of digital printing with a high-performance transfer process, making it an ideal solution for custom apparel printing. With their ability to deliver sharp details and vivid colors, DTF transfers cater not only to individual projects but also to professional production runs, making them increasingly popular among designers and entrepreneurs alike. This method also aligns with the growing trend of sustainable printing, as it uses less wasteful techniques compared to traditional methods. In this article, we will dive into the various benefits of DTF printing techniques, exploring how they are revolutionizing the apparel industry and enhancing custom design possibilities.

Digital Transfer Film (DTF) technology, often recognized for its sophisticated yet user-friendly approach to printing, has become a preferred choice for many looking to create custom designs. This method involves using transfer films to convey high-resolution images and graphics onto fabrics, allowing for the production of intricate apparel designs with ease. Known for its capacity to adapt to different textiles, the DTF printing process simplifies the production of personalized garments. In addition, DTF transfers are gaining traction as a sustainable printing solution, emphasizing efficiency and resource conservation. As we delve deeper, we will uncover how this printing technique not only transforms the creative possibilities in apparel but also promotes eco-friendly practices.

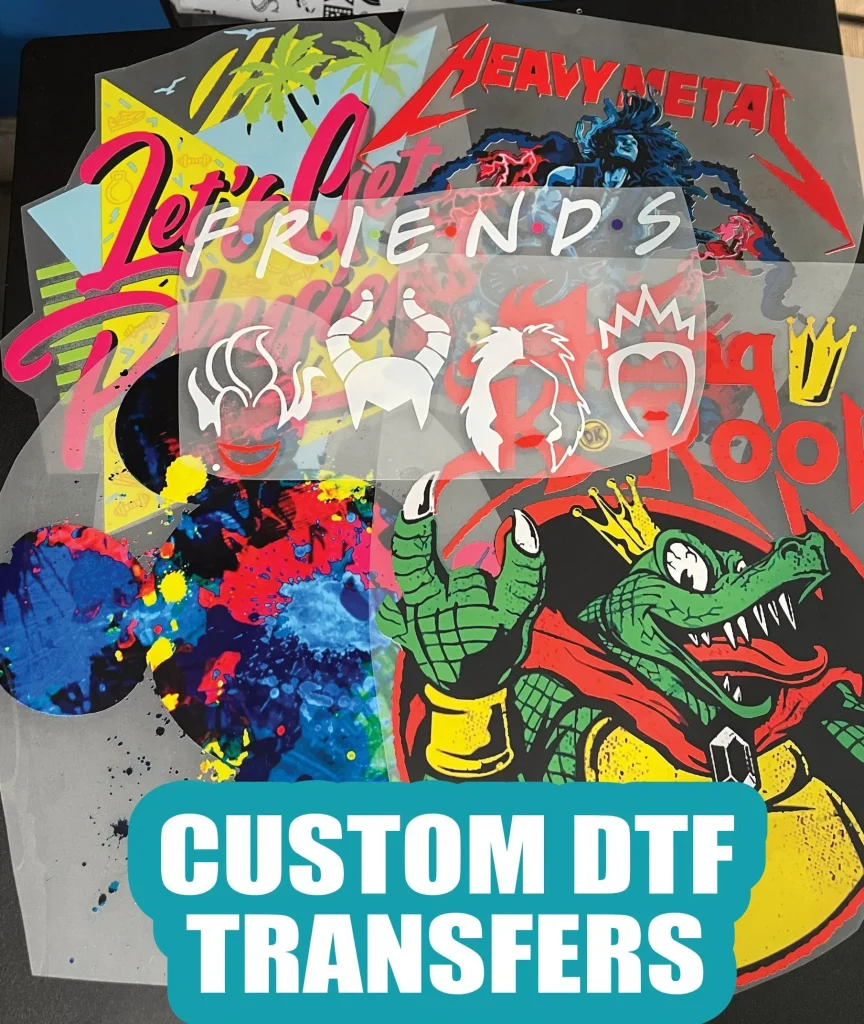

The Versatility of DTF Printing in Custom Apparel

DTF transfers are revolutionizing the landscape of custom apparel by offering unmatched versatility. Unlike traditional printing methods that are restrictive in terms of fabric compatibility, DTF printing excels in its ability to adhere to a wide array of textiles, including cotton, polyester, and even blends. This flexibility allows designers to create unique garments that cater to diverse customer preferences, whether they are producing fashion-forward streetwear or comfortable, casual apparel. Moreover, the vibrant colors and intricate details achievable with DTF technology make it a sought-after choice for creative individuals aiming to stand out in a competitive market.

In addition to fabric versatility, DTF transfers can be used for a plethora of design styles, from bold graphics to delicate line art. This adaptability empowers designers to experiment with various techniques, adding layers of dimension to their work. As a result, the fashion industry is witnessing a shift towards personalization, with consumers increasingly drawn to custom pieces that reflect their individuality. Thus, DTF printing is not just a method—it’s a catalyst for creativity that helps brands push boundaries and redefine contemporary fashion.

Advantages of DTF Transfers Over Traditional Printing Methods

When evaluating the benefits of DTF transfers, several standout advantages emerge that position this technology ahead of traditional printing methods like DTG and screen printing. One of the most notable benefits is cost-effectiveness. DTF printing requires lower setup costs, making it particularly attractive for small businesses and independent artists who may have limited budgets. This financial accessibility allows more creatives to enter the market and produce custom designs without the fear of incurring significant expenses.

In terms of efficiency, DTF transfers significantly reduce the time taken to produce high-quality apparel. The process is streamlined, involving fewer steps and less preparation compared to other printing techniques. This efficiency translates to quicker turnaround times, which is essential for businesses that need to fulfill orders rapidly in today’s fast-paced market. Overall, DTF technology exemplifies how innovation can simplify production processes while maintaining the high standards of quality that consumers expect.

The Role of Sustainability in DTF Transfers

As environmental awareness continues to rise among consumers and brands alike, DTF transfers stand out for their commitment to sustainability. The DTF printing process generates less waste compared to traditional methods, which often require extensive materials and lead to considerable off-cuts and unusable products. By adopting DTF transfers, businesses can significantly reduce their ecological footprint while still delivering beautiful, high-quality designs. This is particularly appealing to eco-conscious consumers who prioritize sustainability in their purchasing decisions.

Moreover, the sustainable aspect of DTF transfers extends beyond waste reduction to include responsible sourcing and the use of eco-friendly inks. Many companies are now focusing on using water-based and non-toxic inks, which further supports ethical production practices. As a result, businesses that utilize DTF technology not only align themselves with environmentally responsible practices but also attract a market segment that values transparency and sustainability in fashion.

Technological Advancements Enhancing DTF Printing

One of the key factors contributing to the growing popularity of DTF transfers is the rapid technological advancements within this printing sector. Manufacturers are investing heavily in research and development to enhance print quality, expand color ranges, and improve overall efficiency. Innovations such as higher resolution printing capabilities enable businesses to create even more intricate designs with an impressive array of vivid colors, elevating the level of professionalism in custom apparel.

Additionally, modern DTF printers are designed to handle larger volumes without compromising on detail or vibrancy. This ability to scale production meets the demands of an expanding market, particularly as e-commerce and personalized apparel continue to grow. As technology evolves, it paves the way for new opportunities within the custom printing industry, making DTF transfers an increasingly attractive option for designers and businesses aiming to stay ahead.

Custom Design Capabilities of DTF Printing

The realm of custom design is incredibly broad, and DTF printing proves to be a powerful tool for bringing artistic visions to life. Designers can create custom graphics that are not only vibrant but also deeply intricate, allowing for personal expressions that resonate with individual consumer identities. The ability to produce small batch runs also encourages creativity, enabling designers to test new concepts without committing to large volumes, ultimately fostering innovation within the fashion landscape.

Moreover, DTF technology allows for easy customization of existing designs, enhancing the user experience in apparel customization. Customers can opt for personalized elements, such as names or specific color choices, leading to unique garment offerings that cater to individual tastes. This level of customization can significantly boost customer satisfaction and loyalty, positioning brands that leverage DTF technology as leaders in the competitive apparel market.

Future Trends in the DTF Transfer Market

The DTF transfer market is poised for substantial growth as trends demonstrate a clear shift towards personalized and expressively designed apparel. The rise of digital commerce has paved the way for increased consumer demand for unique items, which DTF printing can fulfill perfectly. As online selling platforms proliferate, the adaptability of DTF technology allows brands to keep pace with the fast-evolving market landscape, effectively meeting consumer expectations for customization and quick delivery.

Additionally, industry experts predict that as e-commerce becomes increasingly saturated, companies that embrace DTF printing will find themselves at a significant advantage. The versatility and quality of DTF transfers not only streamline production processes but also enable brands to capitalize on emerging trends in fashion and design. By staying attuned to market changes and consumer preferences, businesses utilizing DTF technology are well-equipped to thrive in a dynamic and competitive environment.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct Transfer Film transfers, are an innovative printing method that involves digitally creating a design, printing it onto a special transfer film, and then heat-pressing it onto fabrics. This process enables the transfer of vivid colors and intricate details onto various materials, making DTF a versatile choice for custom apparel production.

Why are DTF transfers considered a sustainable printing option?

DTF transfers are seen as a sustainable printing option because they generate less waste compared to traditional methods and require fewer resources. By minimizing material usage and energy consumption, DTF technology aligns with the growing demand for environmentally responsible practices in the fashion industry.

How do DTF transfers compare to Direct-to-Garment (DTG) printing?

DTF transfers offer a cost-effective and efficient alternative to Direct-to-Garment (DTG) printing. While DTG is great for detailed prints, DTF can accommodate a wider range of fabrics and provides quicker turnaround times, making it an ideal solution for small businesses and custom design projects.

Can DTF transfers be used for a variety of fabric types?

Yes, DTF transfers are highly versatile and can be applied to a variety of fabric types, including cotton, polyester, and blends. This flexibility makes DTF a popular choice for custom designs on different apparel products.

What makes DTF printing an ideal choice for small business owners in the custom design market?

DTF printing is ideal for small business owners because it has lower setup costs and fewer preparatory steps compared to traditional methods. This affordability allows for smaller production runs of custom designs, catering to niche markets and individual customer needs without financial strain.

What trends are influencing the future of DTF transfers in custom design?

The future of DTF transfers is greatly influenced by rising e-commerce demand and the growing trend for personalized apparel. As consumers increasingly seek unique and customizable clothing options, DTF technology is positioned to meet these needs while promoting sustainable practices in the industry.

| Aspect | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers involve digitally creating designs, printing them onto transfer film, and heat-pressing onto fabrics. |

| Advantages | 1. Flexibility to work with various materials, 2. Affordable setup costs for small businesses and hobbyists, 3. Efficient production with quick turnaround times. |

| DTF vs. Other Methods | Cost-effective, detailed prints that rival traditional screen printing, and a streamlined process. |

| Technological Advances | Improvements in print quality, resolution, and capability of handling larger runs. |

| Sustainability | DTF transfers generate less waste and require fewer resources, appealing to eco-conscious consumers. |

| Market Trends | Growing demand for personalization and e-commerce leads to expansion in the DTF transfer market. |

Summary

DTF transfers have revolutionized the custom design process, combining creativity with high-quality apparel production. By enabling detailed and vibrant prints on various fabrics while being cost-effective and sustainable, DTF transfers cater to the needs of modern designers and consumers alike. As technology continues to improve and market demand increases, DTF transfers are not just a passing trend but are set to play a central role in the future of the fashion industry. Embracing DTF technology can provide both businesses and creators with unique opportunities for innovation and style.