DTF transfers are revolutionizing the world of custom apparel and making it easier for businesses to create stunning designs efficiently. This innovative technique, known as Direct-to-Film printing, allows designers to produce vibrant and detailed prints that adhere seamlessly to various fabrics. As the demand for personalized clothing continues to rise, understanding the DTF transfer process becomes crucial for anyone looking to thrive in the custom apparel industry. With its streamlined approach and no need for weeding like traditional heat transfer printing, DTF offers both speed and quality. In this guide, we’ll explore the ins and outs of DTF printing to help you get started on your journey to creating eye-catching apparel.

Also referred to as direct film transfers, DTF printing utilizes a unique method that merges digital printing and heat transfer techniques for custom designs. This process has gained traction among both hobbyists and professional printers for its ability to offer high-resolution outputs on a variety of fabrics. Whether you call it DTF, direct-to-film, or even heat press printing, the underlying technology remains compellingly effective. It transforms intricate artwork into tangible products with durability and vivid color, making it a standout choice in the realm of apparel printing. In our exploration of this trendy printing method, we will detail its benefits, the setup required, and current industry trends to help you harness its full potential.

Understanding DTF Transfers in Custom Apparel

DTF transfers are an innovative way to create custom apparel, revolutionizing how designs are applied to fabrics. By utilizing a specialized printing process, DTF allows for high-quality, vibrant images to be transferred directly onto a variety of materials. This method stands out for its simplicity and effectiveness, making it a favorite among both small and large-scale apparel businesses. Unlike traditional printing techniques, DTF does not require extensive preparation or steps, enabling a faster turnaround time for orders.

The DTF transfer process begins with printing designs onto a special film using high-resolution graphics. This film is then combined with an adhesive powder, which, when cured, forms a strong bond upon heat application. This modern approach to printing caters to various textile needs, allowing for personalized products that meet the rising demand in the custom apparel industry. With DTF transfers, businesses can easily create intricate designs that are both durable and visually appealing.

Step-by-Step DTF Printing Process

To embark on the DTF printing adventure, it’s vital to comprehend the step-by-step process involved. First, create your design using advanced graphic software, ensuring that the artwork is optimized for printing. The next step is to leverage a specialized DTF printer, which uses eco-friendly inks to print designs onto a unique transfer film. After printing, sprinkle adhesives over the wet ink to secure the design and prepare it for heat transfer.

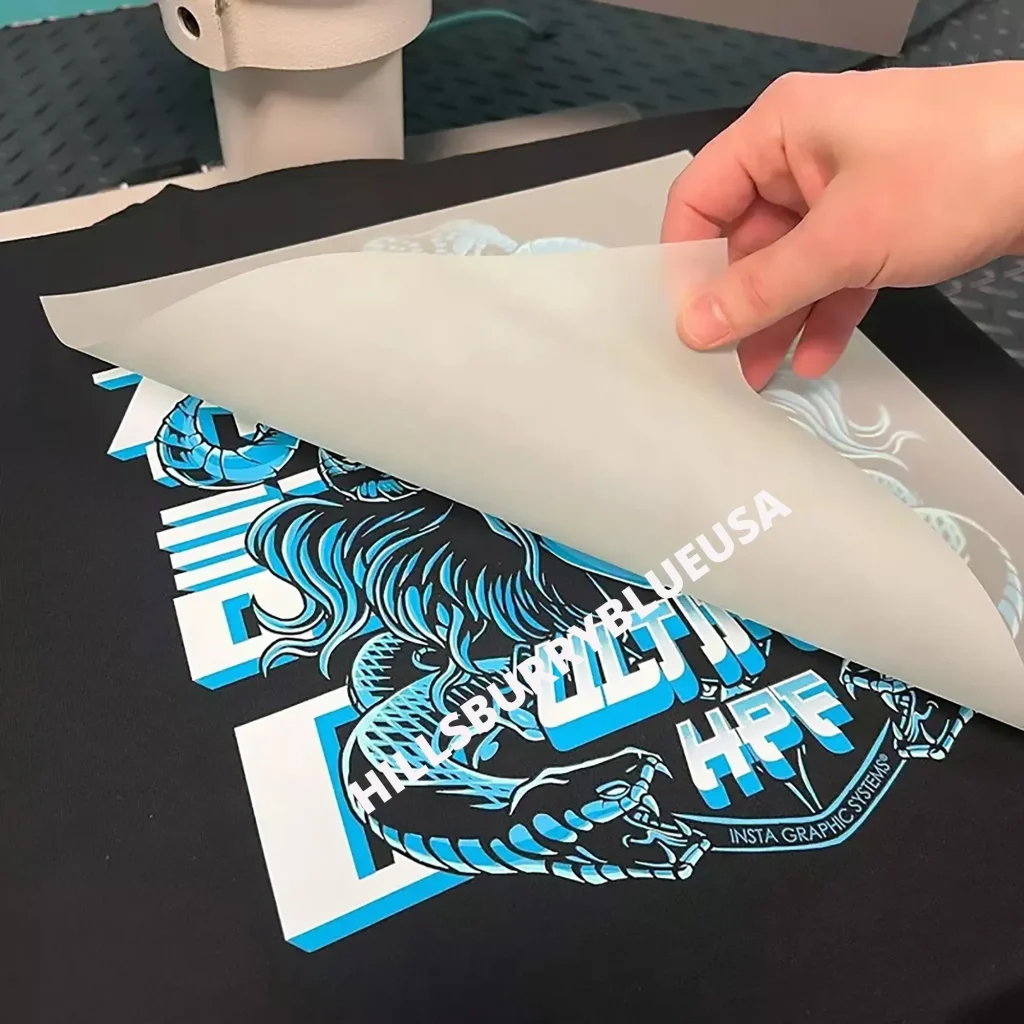

Curing the adhesive is the next critical step, done either with a heat press or an oven to activate the bond. This phase is crucial as it ensures that the design adheres properly to the fabric during the transfer process. Once prepared, the film is placed onto the desired textile, covered with heat-resistant paper, and pressed with a heat source. After cooling, the film is carefully peeled away, leaving behind a stunning and durable design on the garment.

Benefits of Choosing DTF Transfers

DTF transfers come with a myriad of benefits that make them an appealing choice for custom apparel creation. Primarily, they offer high-quality outputs that are not only vibrant but also long-lasting, suitable for various fabric types including cotton and polyester. This versatility allows printing businesses to cater to a broader range of customers, enhancing their product offerings and market reach.

In addition to the quality, DTF printing is cost-effective for short production runs. Startups can print on demand, significantly reducing waste and inventory costs associated with traditional printing methods. Furthermore, the simplified process, which eliminates the need for weeding, enables businesses to increase production efficiency and focus on design creativity rather than labor-intensive procedures.

Setting Up Your DTF Transfer Business

Launching a DTF transfer business requires careful planning and strategic choices. The first step is to identify and research your target market to understand their preferences and trends within the apparel industry. By knowing your audience, you can tailor your offerings to meet their specific needs, which is crucial in a competitive landscape.

Next, investing in high-quality equipment becomes essential. This includes acquiring a reliable DTF printer, heat press, and the necessary supplies like transfer film and adhesive powder. Building solid relationships with suppliers who can provide consistent quality materials will significantly enhance your production capabilities. Moreover, continually improving your skills and knowledge of DTF processes will ensure your business stays competitive and innovative.

Current Trends in DTF Printing

The field of DTF printing is rapidly evolving, with several current trends shaping its future. One such trend is sustainability; as businesses look for ways to minimize their environmental impact, using eco-friendly inks and materials is becoming increasingly vital. DTF printing is advantageous in this regard as it typically uses less water compared to traditional printing methods, catering to a growing demand for greener solutions.

Additionally, advancements in DTF technology are making it easier for newcomers to enter the market. Newer printers with enhanced capabilities and faster output are being introduced, enabling businesses to increase their productivity. The expansion of product offerings is another significant trend, as companies utilize DTF’s versatility to produce not only custom apparel but also items like bags and promotional materials for various events.

Educational Resources for DTF Printing

Knowledge is key in mastering DTF printing and establishing a successful business. Various educational resources, such as comprehensive guides and specialized books, provide invaluable insights into the DTF printing process. For instance, ‘The Complete Guide to DTF Printing’ by Printavo serves as an excellent framework to grasp the fundamental aspects of the technology and business model.

Furthermore, online platforms like ScreenPrinting.com and Printwear Magazine offer regular updates on current trends and best practices. These resources are crucial as they keep you informed about the latest innovations and strategies in DTF printing, facilitating continuous improvement and adaptation in your business practices.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves printing a design onto special film using a DTF printer, then applying an adhesive and a heat press to transfer the design onto fabric. This method eliminates the weeding step found in traditional printing methods, making DTF transfers quicker and easier to manage.

Why should I choose DTF transfers over sublimation printing for custom apparel?

DTF transfers are versatile and can print on a variety of fabrics like cotton, polyester, and blends, unlike sublimation printing, which is limited to polyester materials. This flexibility allows for unique custom apparel options with DTF printing.

Can DTF transfers be used to create high-quality custom apparel?

Yes, DTF transfers provide high-resolution images with vibrant colors and excellent detail, making them ideal for high-quality custom apparel. The prints are long-lasting and maintain their appearance after multiple washes.

What type of equipment do I need to start a DTF printing business?

To start a DTF printing business, you will need a specialized DTF printer, a heat press machine, transfer film, and adhesive powder. Investing in high-quality equipment ensures better results and efficiency in your production process.

Is the DTF transfer printing process suitable for small production runs?

Absolutely! DTF transfer printing is cost-effective for small to medium production runs. It allows you to print on demand, reducing waste and inventory costs, making it perfect for businesses just starting out.

How does the curing process work in DTF transfers?

In the DTF transfer process, after printing your design, you sprinkle adhesive powder over the wet ink and then cure it in a heat press or oven. This step activates the adhesive, ensuring a strong bond during the subsequent heat transfer to fabric.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs onto a special film and transferring them onto fabrics using heat. |

| Benefits of DTF Transfers | High quality, versatile across materials, cost-effective for small runs, and a simplified production process. |

| DTF Printing Process Steps | 1. Design Creation 2. Printing 3. Applying Adhesive 4. Curing the Adhesive 5. Transfer to Fabric 6. Peeling the Film |

| Setting Up DTF Business | Identify market, acquire equipment, build supplier relationships, and develop skills. |

| Current Trends in DTF Printing | Sustainability, growth in product offerings, and improvements in technology. |

Summary

DTF transfers represent a breakthrough in the custom apparel printing sector, combining high-quality output with an efficient and cost-effective process. By grasping the intricacies of DTF transfers, entrepreneurs can tap into a flourishing market, offering vibrant and durable designs across a variety of fabrics. As the DTF printing landscape continues to evolve, staying informed about trends and best practices will be essential for success. Starting your DTF printing journey can lead to limitless creative possibilities in custom merchandise.