DTF transfers, or Direct-to-Film transfers, are revolutionizing the landscape of custom apparel printing with their innovative approach to garment decoration. This cutting-edge technology merges the best of both direct-to-garment (DTG) printing and heat transfer processes, allowing for vibrant, intricate designs that stand the test of time. One of the key DTF printing advantages is its ability to print on a wide variety of fabrics, including cotton and polyester, making it a versatile option for decorators and businesses alike. Moreover, DTF transfers are known for their durability and quality, providing cost-effective printing methods that do not compromise on aesthetic appeal. As we dive deeper into the world of DTF transfers, you’ll discover how this technology is reshaping ways we think about custom apparel and garment decoration techniques.

Direct-to-Film printing, often known simply as DTF printing, emerges as a transformative solution in the realm of textile decoration. This modern technique is gaining popularity for its ability to produce high-quality, long-lasting prints on diverse fabric types, which expands the options available to custom apparel makers. The advantages of using DTF technology include ease of application and minimal setup costs, marking it as a preferred choice for those looking to create stunning designs economically. Additionally, this method showcases remarkable capacity for detail in artwork, allowing businesses to cater to varying styles and demands within the fashion industry. By leveraging innovative printing techniques like Direct-to-Film, entrepreneurs can enhance their offerings and maximize their creative potential in garment decoration.

The Growing Popularity of DTF Transfers in the Custom Apparel Industry

DTF transfers have garnered significant attention in the custom apparel industry, primarily due to their unmatched versatility and ease of use. As more garment decorators and small business owners seek efficient methods to produce high-quality prints, DTF technology stands out as a compelling solution. This popularity can be attributed to its ability to work on a variety of fabrics, including cotton, polyester, and intricate blends, making it suitable for diverse apparel ranging from casual t-shirts to high-performance sportswear.

Moreover, the rise of e-commerce has fueled the need for businesses to adapt quickly to changing customer demands. DTF transfers enable quick turnaround times without the hefty setup costs associated with traditional screen printing. This means smaller businesses can enter the market with custom designs tailored to their consumers, creating a strong competitive advantage without substantial financial risk.

How DTF Printing Compares to Traditional Printing Methods

In the realm of custom apparel printing, understanding how DTF printing compares to traditional techniques such as screen printing and direct-to-garment (DTG) technology is essential. DTF printing enhances processes by offering superior print quality without the limitations of fabric type that traditional methods impose. For instance, while DTG technology is excellent for cotton fabrics, DTF prints can successfully adhere to various substrates, providing decorators with endless possibilities for customization.

Additionally, when it comes to durability, DTF prints deliver remarkably better results than many traditional methods. Screen printing often suffers from cracking and fading over time, whereas DTF transfers maintain their vibrancy and integrity even after repeated washes. This inherent quality makes DTF an increasingly favored choice, particularly among athletes and organizations looking for long-lasting apparel.

The Key Advantages of DTF Transfers Over Other Processes

When evaluating printing techniques for custom apparel, the advantages of DTF transfers are prominent. First and foremost, the efficiency of the DTF process allows for short-run productions and on-demand printing, catering to the modern market’s need for rapid response times. This agility in production not only meets consumer needs but also minimizes waste—a blessing for sustainability efforts within the apparel industry.

Furthermore, DTF printing utilizes water-based inks, which are safer for both the environment and garment decorators, reducing harmful emissions and chemical use compared to traditional solvent inks. This eco-friendliness aligns with the increasing consumer preference for sustainable and responsible fashion choices, making DTF transfers a smart option for businesses aiming to appeal to environmentally conscious shoppers.

Exploring the Cost-Effectiveness of DTF Printing

In the realm of custom apparel printing, cost efficiency can be a decisive factor for emerging businesses. DTF printing emerges as a leader in affordable options, eliminating the substantial setup costs associated with traditional screen printing. For smaller enterprises, this technology allows for investment in high-quality prints without the financial strain of bulk orders or complex machinery.

Moreover, DTF’s capability for printing intricate designs efficiently means that entrepreneurs can capitalize on the rise of personalized apparel without incurring prohibitive expenses. In contrast to methods requiring extensive labor and materials, DTF streamlines the printing process, making it an appealing choice for budget-conscious decorators looking for profitability.

Assessing Recent Trends in DTF Technology Innovations

As the custom apparel market continues to evolve, the recent trends surrounding DTF technology warrant close examination. With advancements in equipment and materials, today’s DTF printers yield even higher quality outputs than earlier models, capturing intricate details with stunning clarity. Innovations such as improved ink formulations ensure more vibrant colors and better adherence to fabrics, pushing the boundaries of what decorators can achieve.

Additionally, manufacturers are focusing on streamlining the user experience, making DTF equipment more accessible for smaller shops and hobbyists. As a result, this democratization of technology has led to a surge in small businesses entering the apparel market, empowering a new generation of designers to leverage DTF for their creative visions.

Industry Feedback: Opinions on DTF Technology Adoption

Industry feedback regarding DTF printing reveals a consensus among decorators regarding its superior flexibility and quality. Many users report high satisfaction levels, citing DTF transfers as a revolutionary addition to their printing arsenal. The ease of application and the minimal setup waste associated with DTF have enabled businesses to experiment with designs without the fear of steep financial losses.

Additionally, testimonials highlight how the ability to print on-demand has transformed inventory management and order fulfillment processes for many companies. As decorators embrace this new technology, they often find that customer satisfaction improves alongside the quality of the finished product, creating a win-win situation for both the businesses and their clientele.

Frequently Asked Questions

What are the main benefits of using DTF transfers for custom apparel printing?

DTF transfers offer numerous advantages for custom apparel printing, including versatility across various fabrics, exceptional print quality, and durability. They maintain color integrity and resist fading, making them perfect for garments intended for regular wear. Additionally, DTF printing is a cost-effective method, particularly for small businesses, as it minimizes setup costs and allows for on-demand production.

How does the DTF printing process work compared to other printing methods?

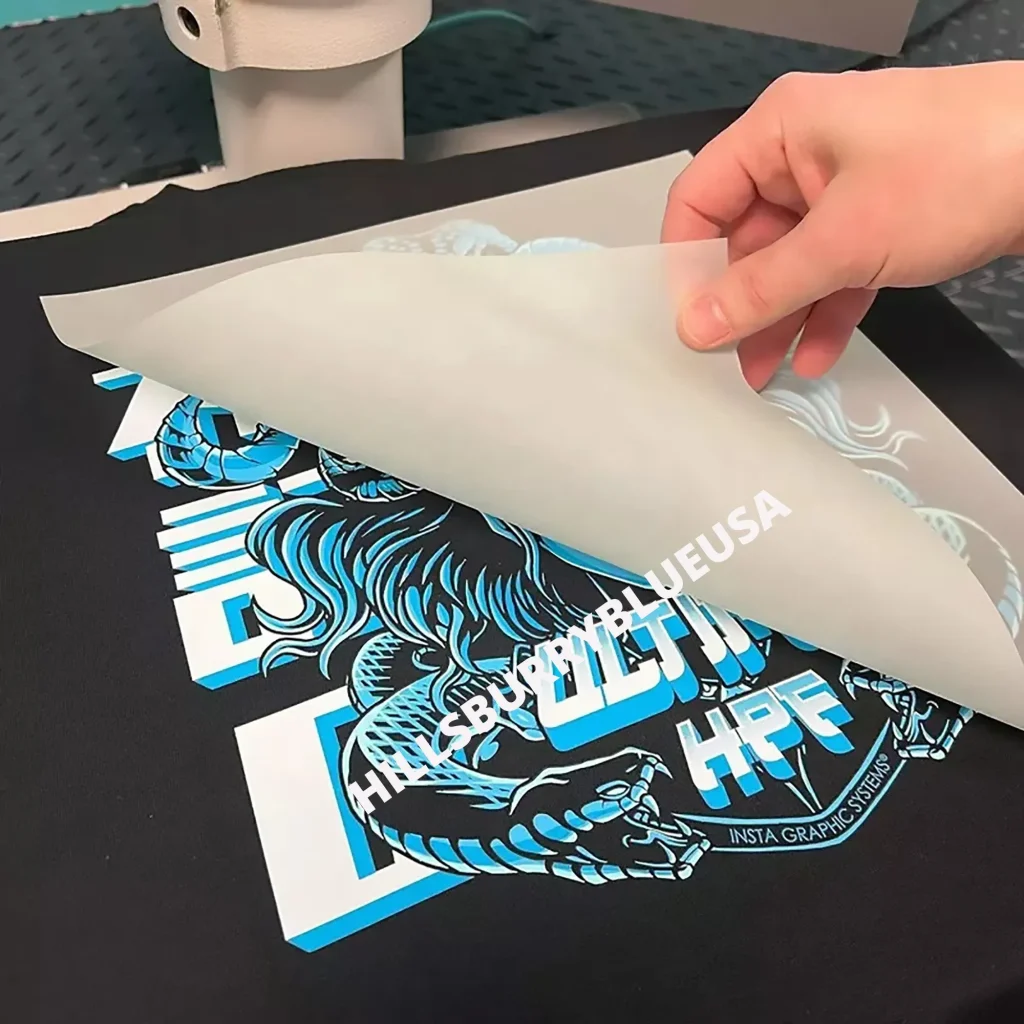

The DTF printing process involves several key steps unique to this technology. Initially, designs are created digitally and printed onto special transfer films using water-based inks. Adhesive powder is then added to create a strong bond, followed by heat curing to secure the ink. Finally, the film is pressed onto the garment, resulting in vibrant, durable designs. This contrasts with methods like screen printing, which can be more labor-intensive and less adaptive to different fabric types.

Is DTF printing a good choice for small businesses in the custom apparel market?

Yes, DTF printing is an excellent choice for small businesses in the custom apparel market. Its cost-effective nature allows for low initial investment, making it ideal for businesses needing to produce small runs or custom designs without incurring high setup costs associated with traditional printing methods. DTF technology enables entrepreneurs to offer high-quality garments without the need for extensive resources.

What types of fabrics can DTF transfers be applied to?

DTF transfers are highly versatile and can be applied to a wide range of fabrics, including cotton, polyester, and their blends. This adaptability allows businesses to serve diverse customer needs and market demands without being limited by fabric type, thus expanding their customization options.

How durable are DTF prints compared to screen printing?

DTF prints are known for their durability and quality compared to traditional screen printing. Unlike screen-printed designs that may crack or fade over time, DTF prints maintain their vibrancy and resist wear from washing. This makes DTF transfers particularly suitable for high-use items like sportswear and fashion apparel.

What recent trends are influencing the growth of the DTF printing market?

Recently, there has been significant growth in the DTF printing market due to increased accessibility and affordability of DTF technology. More small businesses are entering the custom apparel scene, benefiting from faster production times and lower waste generation. Reports indicate a rising demand for DTF printers and consumables, showcasing the technology’s ability to meet modern printing needs and preferences.

| Key Point | Description |

|---|---|

| What Are DTF Transfers? | A modern printing approach combining DTG printing and heat transfer techniques. |

| Process Steps | 1. Design Creation 2. Printing on Film 3. Applying Adhesive 4. Heat Curing 5. Transfer Application |

| Advantages | 1. Versatility on multiple fabrics 2. Exceptional quality and durability 3. Cost-effective for small runs |

| Recent Trends | Growth in DTF technology and increasing small business adoption due to affordability and accessibility. |

| Industry Feedback | Positive adoption experiences with flexibility in design and cost advantages noted by decorators. |

Summary

DTF Transfers are revolutionizing the custom apparel printing industry by providing innovative solutions that meet the evolving demands for quality and versatility. This advanced printing method not only allows for vibrant designs on various fabrics but also offers businesses a cost-effective way to create high-quality products without extensive labor. As more decorators embrace DTF technology, they experience enhanced efficiency, reduced waste, and faster production times, ultimately shaping the future of garment decoration. Entrepreneurs looking to tap into the custom apparel market should consider adopting DTF Transfers to stay competitive and meet customer expectations.