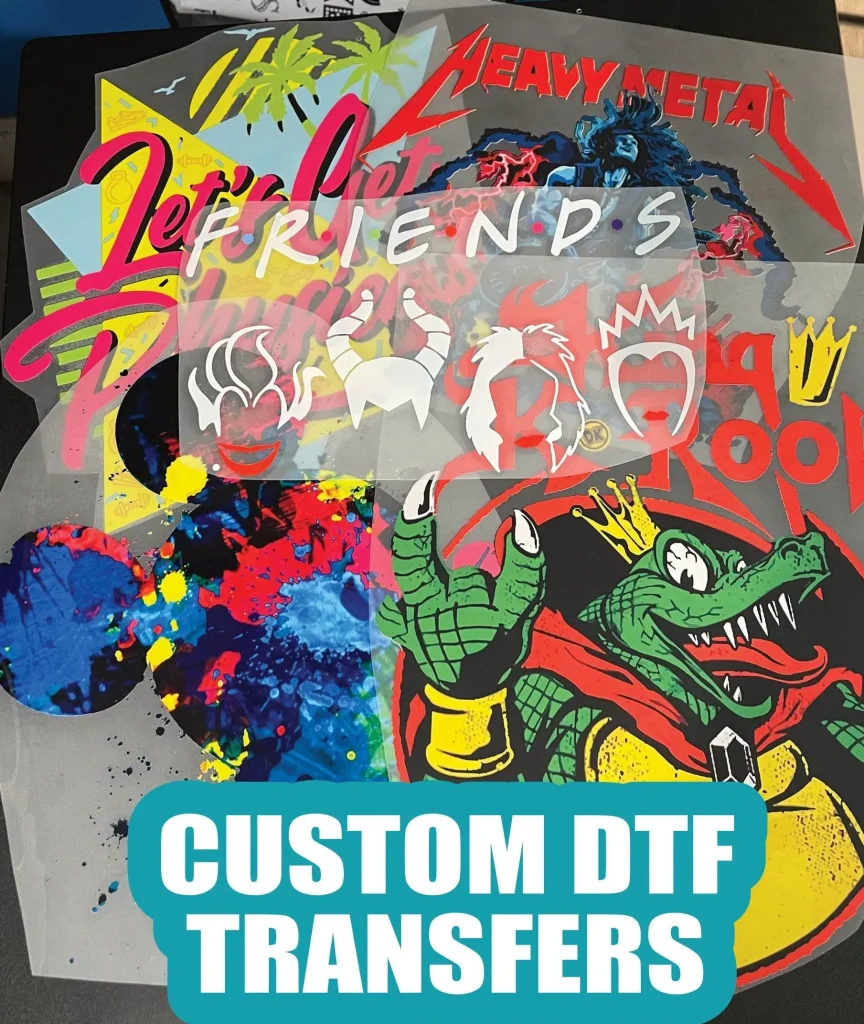

DTF transfers, or Direct-to-Film transfers, are transforming the custom apparel landscape with their innovative printing technique. This cutting-edge method involves applying designs onto a special transfer film, which is then heat pressed onto various fabrics, ensuring durable and vibrant prints. Among the numerous benefits of DTF transfers, their impressive versatility allows for impeccable results on both light and dark materials, making them a popular choice for everything from sportswear to basic T-shirts. In this comprehensive guide, we will delve into the intricacies of the DTF printing process, highlight the many advantages it offers, and explore its wide-ranging applications within the industry. If you’re contemplating adding DTF printing to your creative arsenal, this resource will equip you with essential knowledge to make smart decisions.

Also referred to as Direct-to-Film printing, DTF transfers are redefining how businesses and individuals approach custom designs on garments. This modern printing technique utilizes specialized film that carries vibrant ink, allowing for a precise and durable transfer onto different fabric types. The advantages of using DTF transfers extend beyond mere aesthetics, offering various benefits such as cost-effectiveness and ease of use for printing professionals. DTF printing applications are vast and varied, catering to the needs of fashion designers, promotional product creators, and DIY enthusiasts alike. In understanding these alternative terms and concepts, you’ll gain a more profound insight into the value and potential of this innovative technique.

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process is a revolutionary approach that transforms the way designs are transferred onto fabrics. It starts with creating a digital design using advanced graphic design software, which ensures that every detail is captured accurately. Once the design is finalized, it is printed onto a specialized transfer film using a high-quality inkjet printer specifically designed for DTF inks. These inks are water-based and provides exceptional color vibrancy, setting the stage for stunning final products.

Following the film printing, an adhesive powder is applied to the wet ink. This powder plays a crucial role as it adheres firmly to the printed design and activates during the heat transfer process. The next step is heat activation, where precise temperatures are employed to melt the adhesive, preparing it for a seamless transfer onto the desired fabric. The final transfer process involves using a heat press, which applies the necessary heat and pressure to ensure that the design sticks to the fabric, resulting in a high-quality print that is vibrant and durable.

The Benefits of DTF Transfers in Custom Apparel

One of the primary advantages of DTF transfers is their remarkable versatility. This printing technique can be used on a variety of fabrics, including cotton, polyester, and blends, enabling creators to work on diverse projects ranging from T-shirts to high-performance athletic wear. The adaptability of DTF printing means that businesses can customize items according to their target market’s needs without being restricted by fabric type, opening doors for more creative possibilities.

Additionally, the durability of DTF transfers is unmatched; the prints produced are highly resistant to fading and cracking, even after multiple washes. This long-lasting quality is especially beneficial for businesses that want to provide their customers with high-quality products that withstand the test of time. Furthermore, DTF printing is often more cost-effective for small runs and unique custom designs, making it an attractive choice for startups and small enterprises looking to carve out a niche in the competitive apparel market.

DTF Printing Applications Across Industries

The applications of DTF transfers span a wide range of industries, showcasing the technique’s remarkable adaptability. In the fashion sector, designers can leverage DTF printing technology to develop unique apparel collections that stand out in a crowded market. Its ability to produce vibrant and intricate designs makes it ideal for fashion-forward brands looking to make a statement.

In the promotional merchandise industry, DTF printing serves as a perfect solution for businesses seeking to create branded items, such as T-shirts, tote bags, and caps. The clarity and vibrancy of the prints not only enhance the aesthetic appeal of promotional products but also reinforce brand identity, turning everyday items into powerful marketing tools. Beyond businesses, DTF printing also caters to the DIY community, enabling hobbyists to create personalized gifts and custom apparel for friends and family, further demonstrating its versatility.

Challenges of DTF Transfers and How to Overcome Them

Despite the numerous benefits that DTF transfers offer, there are some challenges that businesses and individuals should be aware of before diving into DTF printing. One significant hurdle is the initial equipment costs associated with purchasing a high-quality inkjet printer and a professional heat press. The investment can be daunting for smaller operations or new entrepreneurs, so it’s essential to weigh the potential return on investment against these upfront costs.

Additionally, mastering the DTF printing process entails a learning curve. Understanding the nuances of the DTF technique, such as the appropriate temperatures for heat activation and the right amount of pressure during transfers, is critical for achieving optimal results. Aspiring printers can mitigate these challenges by participating in workshops, accessing online tutorials, and practicing with the equipment to build confidence and skills.

Exploring the Future of DTF Printing

As technology continues to evolve, the future of DTF printing appears bright. Innovations in inks, transfer films, and printing equipment promise to enhance the efficiency and quality of the DTF printing process. With advancements like faster printing speeds and improved adhesion techniques, DTF transfers are expected to become even more accessible and user-friendly for businesses of all sizes.

Further, the growing demand for personalized and custom apparel suggests a robust market for DTF printing in the coming years. As sustainability becomes a higher priority, DTF transfers will also play a significant role with their ability to produce smaller batches of apparel while maintaining high-quality standards. By staying informed on the latest industry trends and technologies, businesses can leverage DTF printing to capture new opportunities and meet consumer preferences.

Integrating DTF Transfers into Your Business Model

For businesses looking to incorporate DTF transfers into their offerings, understanding the market demand is fundamental. Conducting thorough research into customer preferences and current design trends can help businesses effectively position their products. By offering customized apparel through DTF printing, companies can create a unique selling proposition that resonates with consumers who value personalization and originality.

Implementing DTF transfers into an existing business model may also require adjustments in operational processes. Ensuring that production workflows are optimized for DTF printing will lead to greater efficiency and improved output. This might include training staff on the technical aspects of the printing process or streamlining the design approval workflows to accommodate faster turnaround times for custom orders.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special transfer film which is then applied to fabric using heat and pressure. This innovative DTF printing process allows for vibrant designs on various textiles, making it an effective method for custom apparel.

What are the primary benefits of using DTF transfers?

The benefits of DTF transfers include versatility on multiple fabric types, durability of prints that resist fading, vibrant color reproduction, cost-effectiveness for small runs, and ease of use for newcomers to the printing industry.

Can DTF printing be applied to different fabric types?

Yes, DTF printing is highly versatile and can be applied to a wide range of fabrics, such as cotton, polyester, and blends. This adaptability makes DTF transfers suitable for diverse applications, from t-shirts to sportswear.

How does the DTF printing process compare to traditional screen printing?

Unlike traditional screen printing, the DTF printing process offers easier setup for small batches and customized designs at a lower cost. DTF transfers produce high-quality prints with detailed color vibrancy and can be used on both light and dark fabrics.

What industries can benefit from DTF printing applications?

DTF printing applications span various industries, including fashion for unique apparel design, promotional merchandise for custom items, sportswear production, and personal projects for hobbyists seeking to customize textiles.

What challenges should I consider when using DTF transfers?

Some challenges of DTF transfers include the initial setup costs for quality printers and heat presses, the learning curve associated with mastering the DTF printing process, and the importance of applying correct heat and pressure for optimal transfer quality.

| Key Points | Details | ||

|---|---|---|---|

| DTF Transfers Overview | Revolutionizes custom apparel printing with cost-effective, high-quality results. | ||

| Printing Process | 1. Design creation 2. Film printing 3. Powder application 4. Heat activation 5. Transfer process | ||

| Advantages | Versatile, durable, color vibrant, cost-effective, and easy to use. | ||

| Applications | Fashion, promotional merchandise, sportswear, personal projects. | ||

| Challenges | Initial costs, learning curve, application techniques must be mastered. | ||

Summary

DTF transfers are transforming the landscape of custom apparel printing by providing a method that balances affordability with high-quality output. These transfers employ a unique printing technique that allows for incredible detail and vibrant colors on a variety of fabrics. This guide outlines the DTF printing process, emphasizing the ease of use and cost-efficiency for both businesses and personal projects. As individuals and companies explore the possibilities of DTF transfers, they will find that this technology not only meets their printing needs but also elevates the quality and appeal of their products.