In the competitive realm of custom printing, the **DTF Gangsheet Builder** stands out as an essential tool for maximizing production efficiency and profitability. By leveraging a gang sheet, operators not only efficiently utilize their materials but also streamline their design application processes, which is crucial in today’s fast-paced market. This innovative approach can significantly boost your DTF printing efficiency while adhering to best practices in DTF printing. In this article, we’ll delve into practical gang sheet design tips that help you perfect your layouts and enhance overall output. From optimizing ink usage to reducing waste, understanding the benefits of DTF gangsheet builders is key to mastering profitable DTF techniques.

Within the landscape of direct-to-film printing, utilizing a gang sheet design method can greatly enhance operational effectiveness. This strategic approach allows multiple graphics to be printed simultaneously on a single film, promoting cost savings and material efficiency. Moreover, implementing effective gang sheet strategies ensures you achieve high-quality prints while minimizing waste. As we explore this topic further, we’ll uncover various direct-to-film best practices aimed at refining your printing workflow and boosting profitability. By embracing these advanced techniques, your custom printing endeavors can thrive in the highly competitive market.

Maximizing Efficiency with DTF Gangsheet Builder

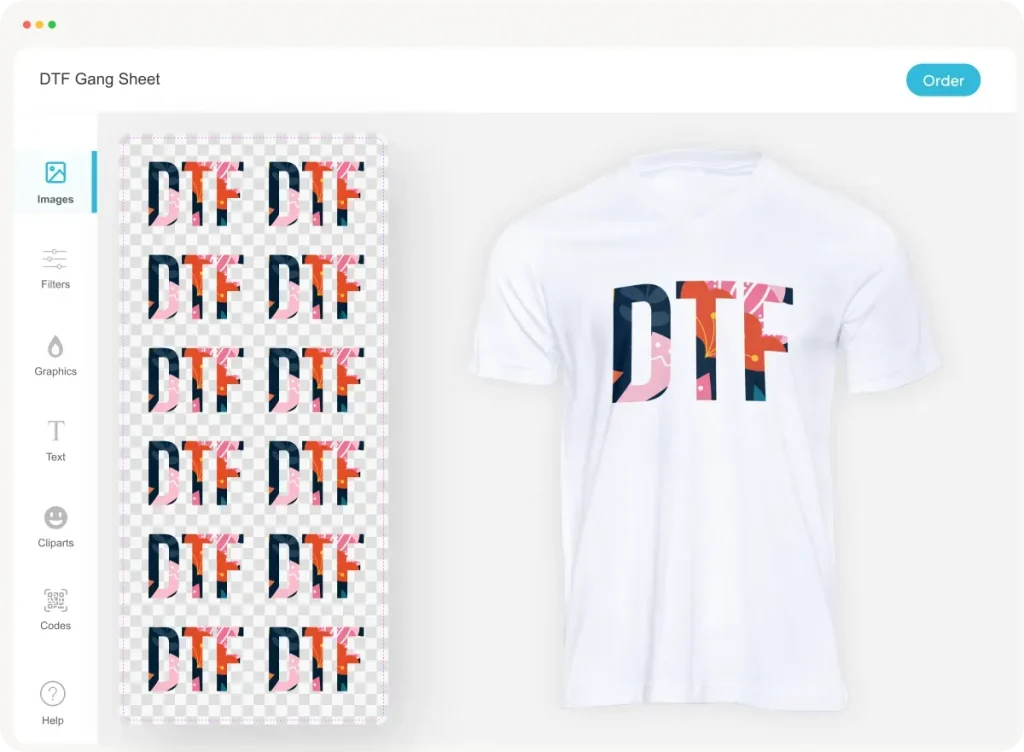

In the realm of custom printing, utilizing a DTF Gangsheet Builder can significantly enhance operational efficiency. This innovative tool allows print operators to arrange multiple designs on a single sheet, optimizing the space and resources used during production. By minimizing waste and maximizing the number of designs per film sheet, businesses can dramatically reduce material costs while increasing output. The strategic layout made possible by gang sheets not only simplifies the printing process but also streamlines future designs, making it easier to scale operations.

Moreover, employing a gangsheet builder facilitates better management of inventory and reduces the time spent on setup and adjustments. Print operators can quickly adapt designs to fit the gang sheet template, which means faster response times to customer orders. By integrating this tool into their workflow, businesses are not only bolstering their production capacity but are also positioning themselves to meet the demands of a competitive market, ultimately boosting profits.

Best Practices for DTF Printing

To achieve stellar results in DTF printing, adhering to best practices is essential. This includes understanding the intricacies of design placement on gang sheets to ensure they are optimally spaced, which can prevent issues like color bleeding and print overlap. The use of design software to visualize arrangements before printing can be a game-changer, allowing for minor adjustments that can enhance the final output. Following established best practices improves not just the efficiency of the process but also the quality of the prints, which is crucial for customer satisfaction.

Additionally, using high-quality inks and maintaining your equipment regularly are critical aspects of best practices in DTF printing. These measures ensure that prints maintain their vividness and durability over time. Operators should also keep themselves updated with the latest DTF printing techniques and materials, as this knowledge can help mitigate common pitfalls and enhance output quality.

Streamlining Gang Sheet Design Tips

Designing an effective gang sheet goes beyond merely placing designs close together to save space; it requires a thoughtful approach to layout. One key tip is to group designs with similar colors together to reduce the need for frequent ink changes during the printing process. This not only conserves ink but also enhances the overall efficiency of the print run. Adopting a systematic approach to design organization on gang sheets can lead to significant savings and improved turnaround times.

Another vital design tip is to consider the size and orientation of each design carefully. Larger designs should have adequate spacing to prevent overlapping while allowing for smaller graphics to fit strategically without compromising quality. Utilizing software that provides templates specifically for gang sheet layouts can streamline this process, making it easier to visualize and adjust as needed. With these tips, print operators can create gang sheets that maximize both productivity and quality.

Common Challenges in DTF Printing

While gang sheets offer numerous advantages, there are common challenges that operators may face. One significant issue is adhesion, where designs may not stick properly to the fabric, leading to peeling or damage upon washing. This problem can often be addressed by regularly maintaining equipment and ensuring that printers are clean. Adjusting settings based on the substrate material can also help improve adhesion and integrity of the prints.

Color mismatches are another prevalent challenge in DTF printing. Variations in ink quality or printer calibration can result in prints that do not accurately reflect the intended colors. It is crucial for operators to use the same brands and types of inks consistently and to conduct regular checks on printer calibration to ensure reliability in color outputs. Addressing these challenges proactively can lead to a smoother printing process and better overall product satisfaction.

Enhancing Profitability Through Strategic Practices

Enhancing profitability in DTF printing is a multifaceted endeavor, particularly when utilizing gang sheets. By carefully analyzing which designs are most popular, print operators can focus on creating more of these high-demand items, thus maximizing their revenue potential. Efficiency in material usage also plays a critical role in profitability; by minimizing waste through meticulous gang sheet planning, businesses can significantly reduce their costs over time.

Additionally, adopting a mindset focused on continuous improvement can lead to increased production runs. Collaborative discussions within team environments, or seeking feedback from customers, can identify areas for operational enhancements. This proactive approach not only leads to better financial outcomes but builds a solid reputation in the industry, driving more customers to choose your services over competitors.

Engaging in Continuous Learning for DTF Excellence

Continuous learning is paramount in the ever-evolving field of DTF printing. Operators and technicians must keep themselves informed about the latest technologies and trends that impact the industry. Engaging with online forums, attending industry workshops, and participating in training sessions can provide valuable insights and practical knowledge that directly improve printing processes and product quality. By investing in learning, businesses ensure they remain relevant and efficient amidst advancements in DTF technology.

Moreover, continuously assessing your printing processes can uncover new opportunities for efficiency enhancements and cost savings. Keeping an open line of communication regarding advancements with team members leads to innovative solutions that can be implemented rapidly. Those who embrace continuous learning not only refine their skills but also elevate the entire operation, driving growth and success in a challenging marketplace.

Frequently Asked Questions

What are the best practices for using the DTF Gangsheet Builder?

To optimize your use of the DTF Gangsheet Builder, focus on proper design arrangement, which includes maintaining adequate spacing between graphics to prevent overlaps, and strategically placing larger designs to accommodate smaller ones. Regular calibration of your printer and using high-quality inks will also enhance print clarity and quality.

How can I improve DTF printing efficiency with a gangsheet?

Improve DTF printing efficiency by utilizing the gangsheet to print multiple designs on a single film sheet. This approach minimizes material costs and waste while speeding up production times. Regular maintenance of your printing equipment and using design software for layout previews can further optimize your processes.

What are some common challenges faced when using a DTF gangsheet for printing?

Common challenges when using a DTF gangsheet include adhesion issues, color mismatches, and print clarity. To tackle these, ensure your print heads are clean, use high-quality inks for consistent color results, and perform regular printer calibrations to maintain clarity in your outputs.

How does gang sheet design impact profitability in DTF printing?

The design of your gang sheet directly impacts profitability by significantly reducing material costs and enhancing production runs. By efficiently organizing popular designs, you can maximize the output and speed of production, allowing for increased revenue and improved margins on high-demand products.

What are some profitable DTF techniques when using a gangsheet builder?

Profitable DTF techniques include analyzing your sales data to focus on high-demand designs, using the gangsheet builder to create streamlined layouts that reduce waste, and ensuring quick turnaround times on production to accommodate more orders, all leading to higher revenue.

How can I stay updated on best practices for DTF printing with gang sheets?

Stay updated on DTF printing best practices by participating in industry forums, attending workshops, and following the latest trends in DTF technology publications. Continuous learning will help you refine your skills and keep your processes competitive in the market.

| Key Point | Description |

|---|---|

| Introduction | DTF technology transforms garment printing, with gang sheets maximizing material use and production efficiency. |

| Understanding Gang Sheets | A method to print multiple designs on one sheet, offering cost savings and reduced waste. |

| Benefits of Using Gang Sheets | 1. Cost Efficiency 2. Reduced Waste 3. Enhanced Production Speed |

| Design Arrangement | Best practices include spacing, optimal placement, and using software tools for layout preview. |

| Common Challenges | Adhesion issues, color mismatch, and print clarity can affect outputs; regular maintenance is essential. |

| Profitability | Reduce costs, increase production runs, and focus on high-demand designs for better profits. |

| Continuous Learning | Stay updated on DTF technologies, engage in forums, and attend workshops to refine skills. |

Summary

The DTF Gangsheet Builder is a pivotal tool for anyone involved in custom printing, enabling the efficient transfer of designs onto garments while maximizing material usage. By understanding the best practices in utilizing gang sheets, addressing potential challenges, and engaging in continuous learning, you can significantly boost your production efficiency and profitability. Leveraging these insights not only enhances the quality of outputs but also positions your business favorably within the competitive printing landscape. As the market evolves, adopting these strategies ensures that your operations remain agile and responsive to the dynamic requirements of DTF printing.